Method for synthesizing ordered macroporous-mesoporous-microporous hierarchical-pore molecular sieve by using hard template

A synthesis method and multi-level pore technology, applied in the direction of crystalline aluminosilicate zeolite, can solve problems such as limitations, and achieve the effects of improving catalytic activity, improving flow and diffusion performance, and shortening material transport paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

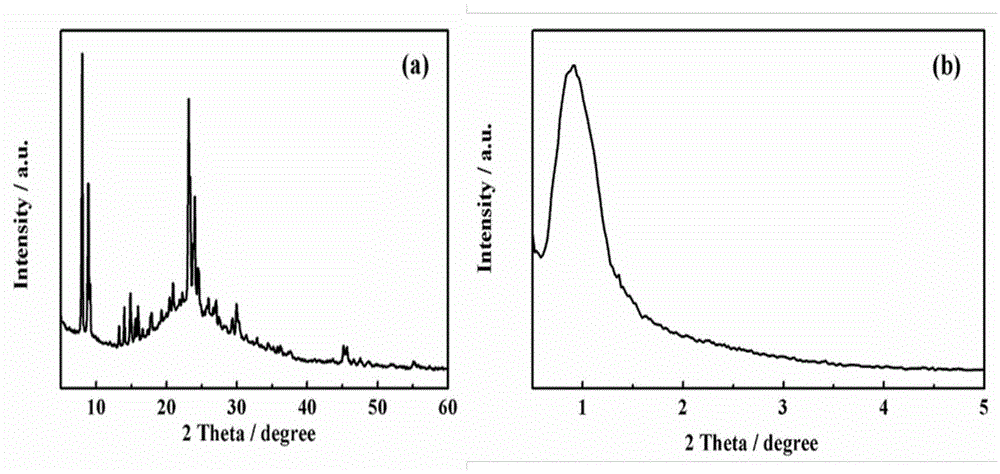

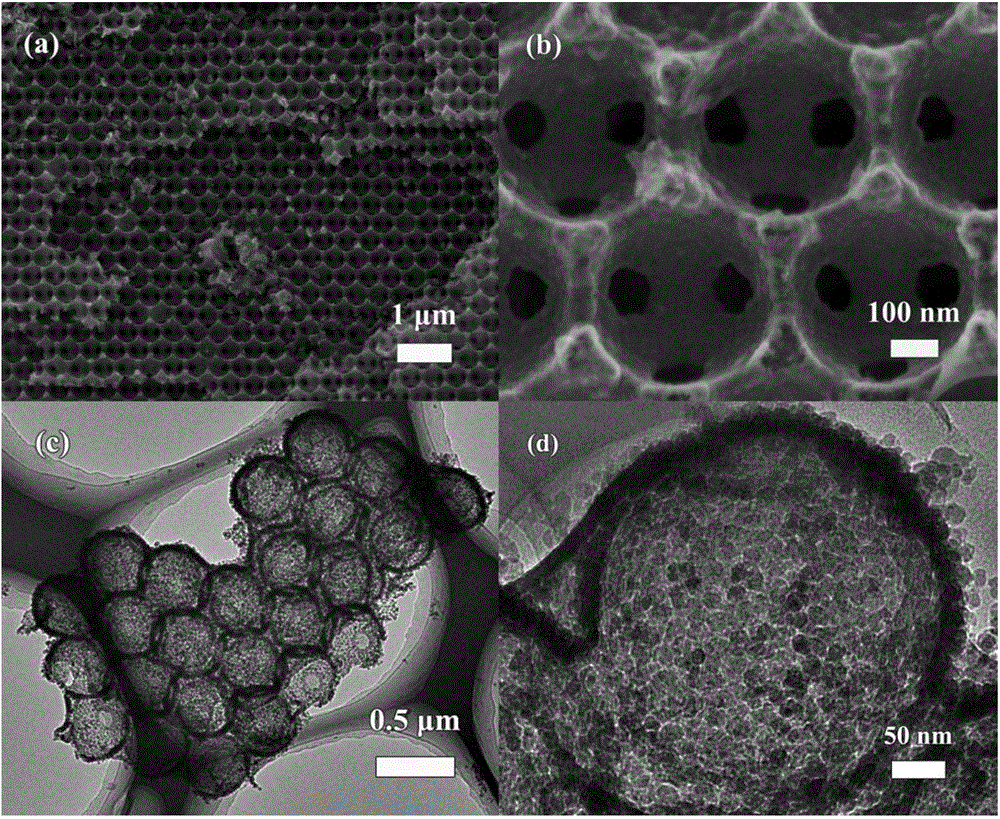

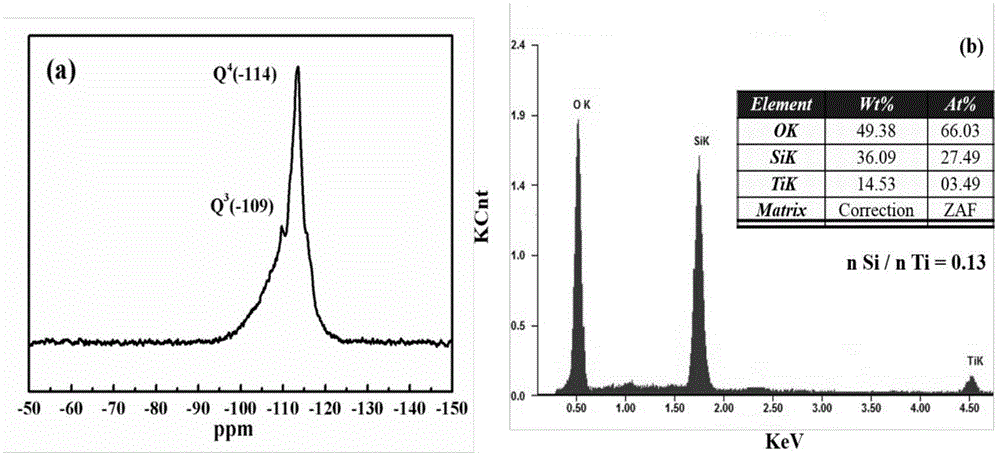

[0036] Example 1 Dissolve 1.52g of 1M aqueous solution of tetrapropylammonium hydroxide in 23.84g of deionized water, then add 0.69g of tetraethylorthosilicate dropwise into the above solution, and stir at 20°C for 24h to obtain a uniform Mixed solution; add 0.75g 10wt% titanium isopropoxide / isopropanol mixed solution to the obtained mixed solution, stir at 20°C for 8h to obtain a precursor solution; add 0.3g ordered macroporous-mesoporous hierarchical The carbon material (macropore diameter is 400nm, mesopore diameter is 20nm) is immersed in 20g of the prepared precursor solution and mixed evenly, the obtained mixture is moved to a 100mL hydrothermal reaction kettle, and hydrothermally heated at 130°C for 12h; the obtained product Wash and filter with deionized water for 5 times, then immerse in the newly prepared precursor solution again, carry out the second hydrothermal reaction under the same conditions, and repeat this 6 times; the final obtained TS-1 molecular sieve nanocr...

Embodiment 2

[0039] Dissolve 1.52g of 1M tetrapropylammonium hydroxide aqueous solution in 23.84g of deionized water, stir evenly, then add 0.69g of tetraethyl orthosilicate dropwise into the above solution, and stir at 20°C for 24h to obtain a uniform 0.10g15wt% titanium isopropoxide / isopropanol mixed solution was added to the mixed solution obtained, and stirred at 20°C for 8h to obtain a precursor solution; 0.4g ordered macroporous-mesoporous multi-level The porous carbon material (with a macropore diameter of 400nm and a mesopore diameter of 20nm) was immersed in 25g of the precursor solution prepared above and mixed evenly, and the obtained mixture was transferred to a 100mL hydrothermal reaction kettle, and hydrothermally heated at 100°C for 12h; The obtained product was washed with deionized water for 5 times and then immersed in the newly prepared precursor solution again, and the second hydrothermal reaction was carried out under the same conditions, and this was repeated 8 times; ...

Embodiment 3

[0042] Dissolve 1.52g of 1M tetrapropylammonium hydroxide aqueous solution in 23.84g of deionized water, stir evenly, then add 0.69g of tetraethyl orthosilicate dropwise into the above solution, and stir at 40°C for 8h to obtain a uniform 2.4g 5wt% titanium isopropoxide / isopropanol mixed solution was added to the mixed solution obtained, and stirred at 40°C for 2h to obtain a precursor solution; 0.2g ordered macroporous-mesoporous multi-level The porous carbon material (with a macropore diameter of 400nm and a mesopore diameter of 30nm) was immersed in 15g of the prepared precursor solution and mixed evenly, and the obtained mixture was transferred to a 50mL hydrothermal reactor, and heated at 110°C for 12h; the obtained The product was washed with deionized water and filtered for 5 times, then immersed in the newly prepared precursor solution again, and the second hydrothermal reaction was carried out under the same conditions, and this was repeated 7 times; the final TS-1 mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com