Full-automatic single wet tissue packaging machine

A wet tissue, fully automatic technology, applied in the field of fully automatic single-piece wet tissue packaging machine, can solve the problems of incorrect folding width of raw materials, waste of raw materials, lower product packaging quality, etc., to solve the problem of insufficient manual inspection and manual counting of sheets Difficulty, the effect of improving the quality of product packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

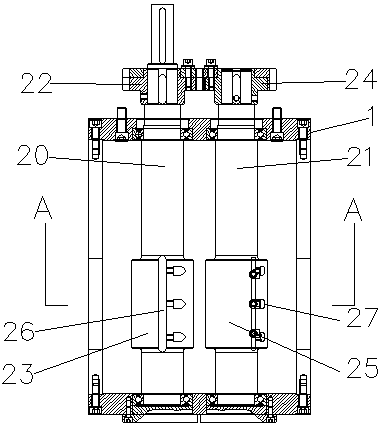

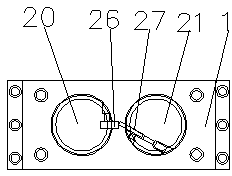

[0041] refer to Figure 1 to Figure 13 As shown, the fully automatic single-piece wet tissue packaging machine includes a frame 1 and an optical fiber probe installed on the frame. The frame 1 is provided with a rotating shaft 10 for fixing raw materials and a conveying device for conveying raw materials. 11. The lifting cylinder 12 for controlling the up and down movement of the conveying device, the deviation correction mechanism 13 for correcting raw materials, the longitudinal folding mechanism 14, the horizontal folding mechanism 15, the cutting mechanism 2, the wrapping mechanism 17, and the rotating shaft for fixing the packaging film 18. Coding machine for printing packaging film 19. Packaging film traction mechanism for conveying packaging film 3, Packaging film longitudinal sealing mechanism 4, Packaging film traction exhaust mechanism 5, Packaging film horizontal sealing mechanism 6, Blowing and rejecting Sprinkler 16, finished product conveyor belt 7, counting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com