Beverage filter bag lifting rope end label connection processing method and production device

The technology of a production device and a processing method is applied in the field of connection processing of labels on the rope end of a beverage filter bag and its production device, which can solve the problems of high label difference and reject rate, slow reaction speed of cylinders, complicated operation and adjustment, etc. Automate production, improve work efficiency, and improve product aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

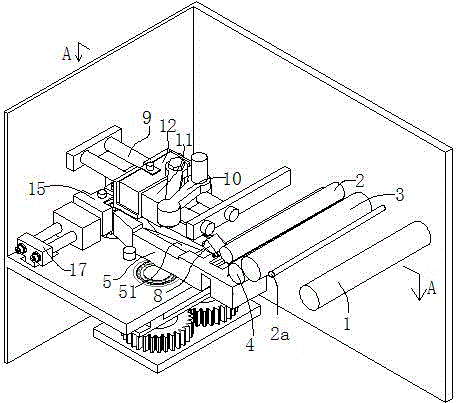

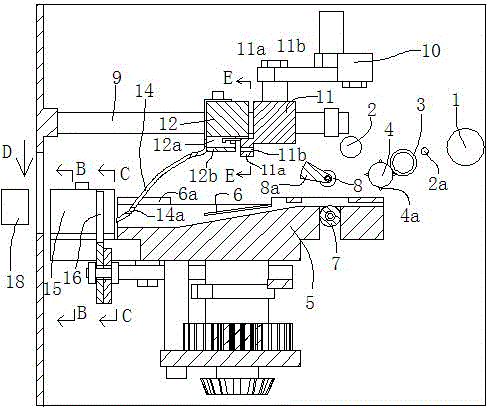

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

[0029] A processing method for connecting and labeling labels at the rope end of a beverage filter bag, including front and back label tapes, carried out according to the following steps:

[0030] (1) Cut out a strip of paper tape, process the transmission positioning notch on the side edges of the paper tape to facilitate the transmission and positioning of the production device, and process the center line of the paper tape along the length direction to facilitate the transmission of the production device Positioned notched through holes, the tape is coated with hot melt adhesive on one side;

[0031] (2) Place the paper tape processed in step (1) on the transmission production line, pass through the notches o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com