Full-automatic paint spraying assembly line

An automatic paint spraying machine and assembly line technology, which is applied in spray booths, spraying devices, coatings, etc., can solve the problems of low independent work efficiency of multiple devices, asynchronous work of multiple devices, and increased cleaning steps. The effect of labor cost, efficiency improvement, and time saving of mold washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

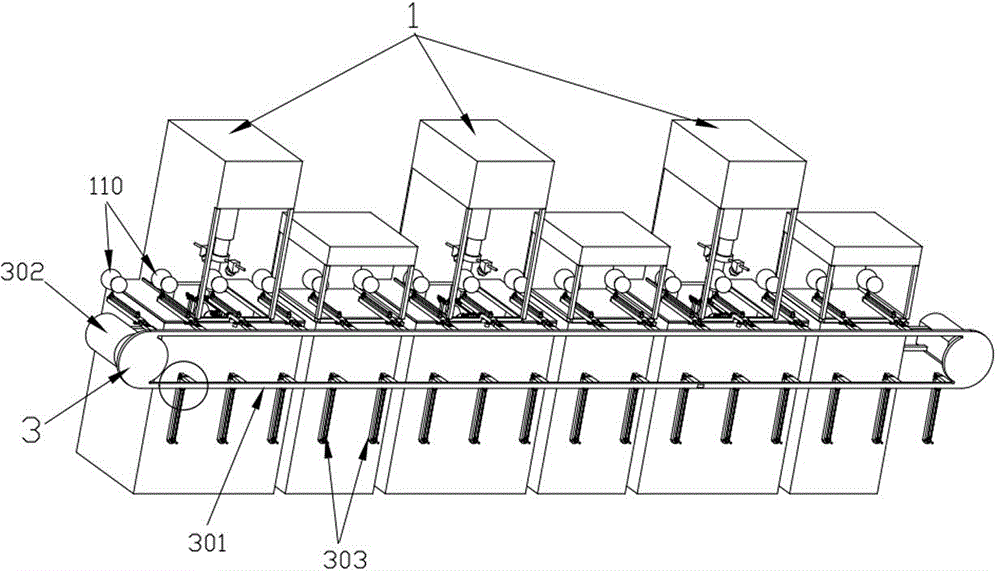

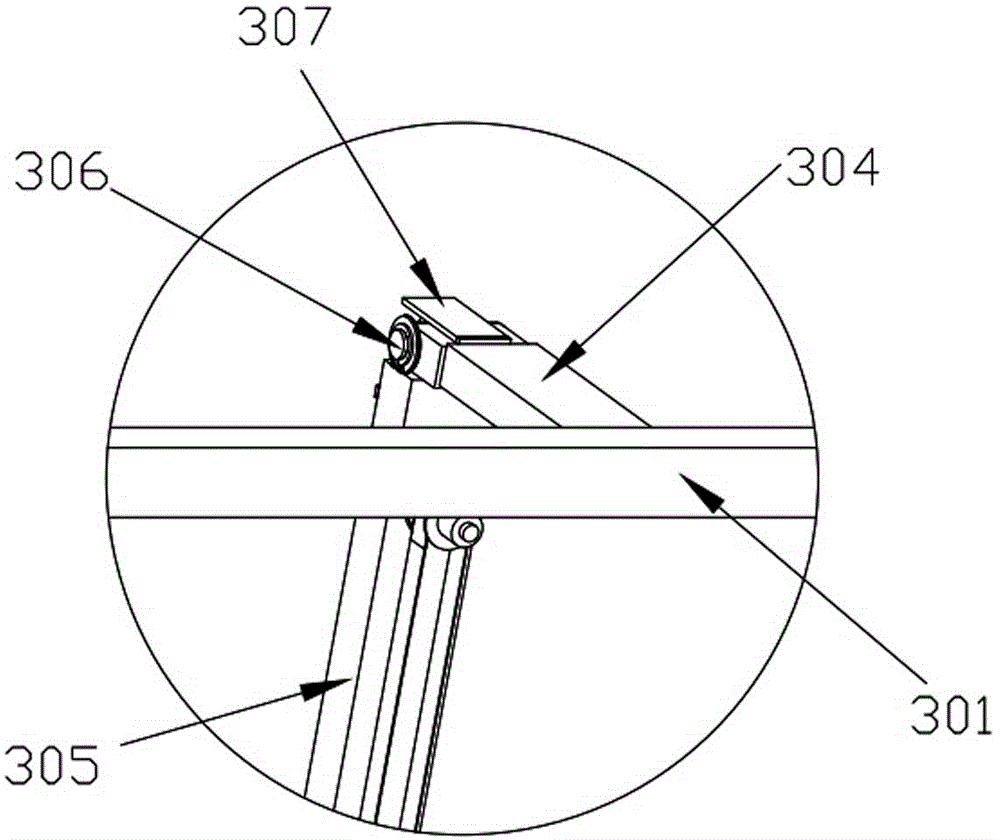

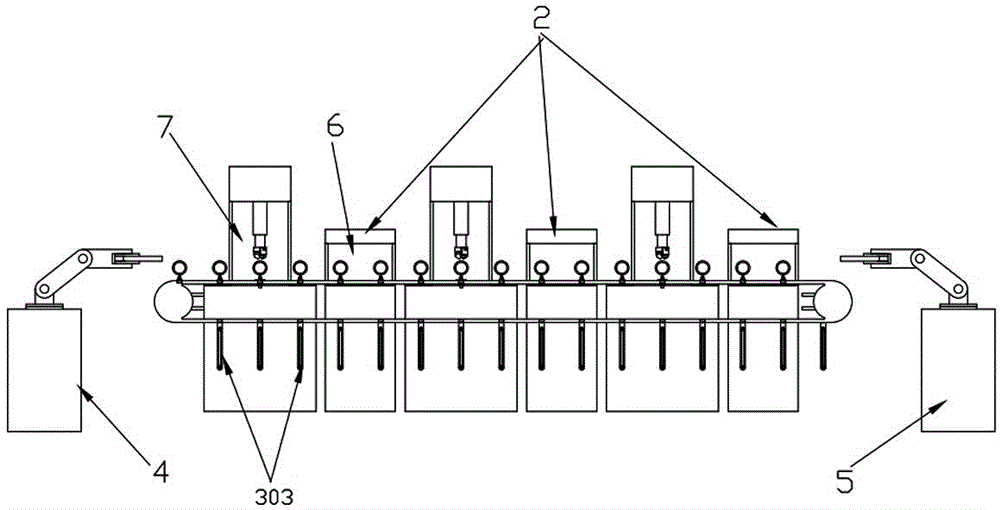

[0038] In this embodiment, refer to Figure 1 to Figure 6 , its specific embodiment includes an automatic paint spraying machine 1, an automatic dryer 2, an automatic assembly line 3, a feeding manipulator 4, an unloading manipulator 5 and a touch screen control platform for intelligently controlling the work of the assembly line.

[0039] Wherein, the automatic paint spraying machine 1 in the present embodiment is provided with three altogether, and the automatic dryer 2 corresponding to its quantity also is provided with three, is respectively positioned at the right side of each automatic paint spraying machine 1, makes automatic paint spraying machine 1 and automatic The dryers 2 are neatly arranged in a straight line. In order to ensure that the next process can be sprayed normally, fast drying is required after each spraying pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com