Vacuum arc-extinguishing chamber with closing self-hold function

A vacuum interrupter and self-holding technology, applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of complex structure of the operating mechanism, accelerated closing action, and difficulty in closing the vacuum load switch. To achieve the effect of simplifying the operating mechanism and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

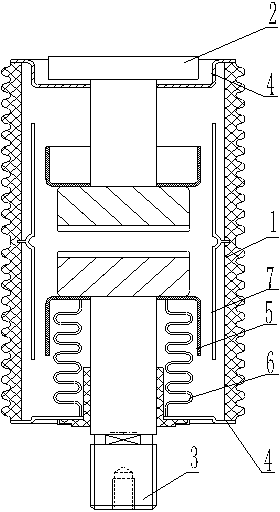

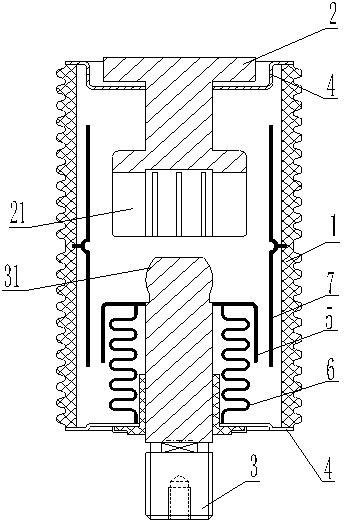

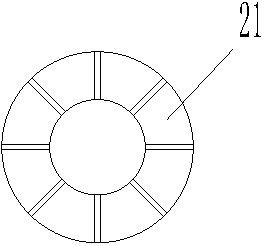

[0020] Embodiment one: if Figure 2~3 As shown, a vacuum interrupter with a closed self-holding function includes an insulating cylinder 1, the two ends of the insulating cylinder 1 are respectively provided with a static contact 2 and a moving contact 3, and the two ends of the insulating cylinder 1 Sealing flanges 4 are also provided, and bellows 6 for sealing are set on the movable contact 3. The insulating cylinder 1, sealing flange 4, static contact 2, moving contact 3 and bellows 6 together form a vacuum space, one end of the static contact 2 and the moving contact 3 passes out of the insulating cylinder 1, and the end of the static contact 2 in the insulating cylinder 1 is formed by several rings Composed of metal flaps 21, the metal flaps 21 form a cylindrical cavity, the end of the movable contact 3 in the insulating cylinder 1 is arc-shaped, and the arc-shaped end 31 is inserted into the cylindrical cavity to make The static contact 2 and the movable contact 3 are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com