Laminate type magnetic ball

A chip and magnetic bead technology, applied in the direction of electrical components, inductors, circuits, etc., can solve the problems of low rated current, limited application range, high DC resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

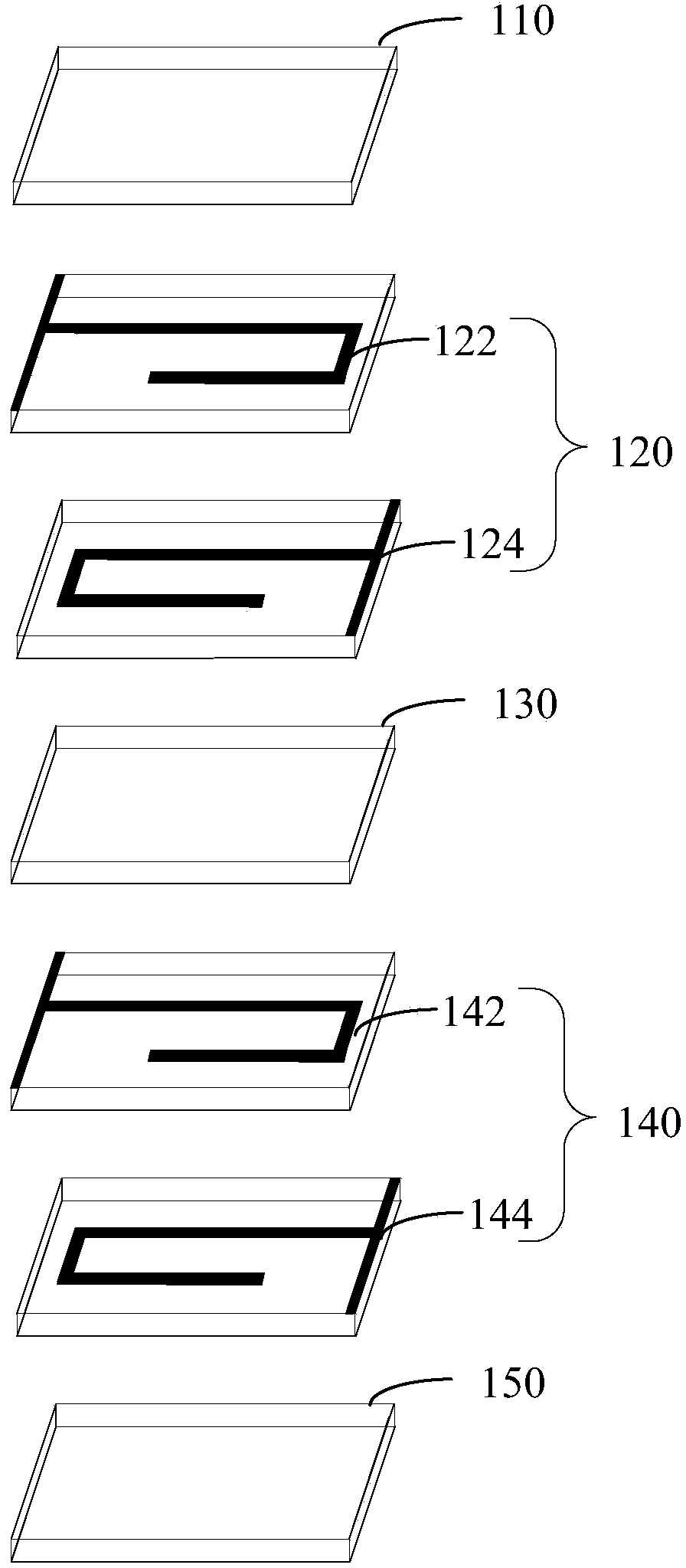

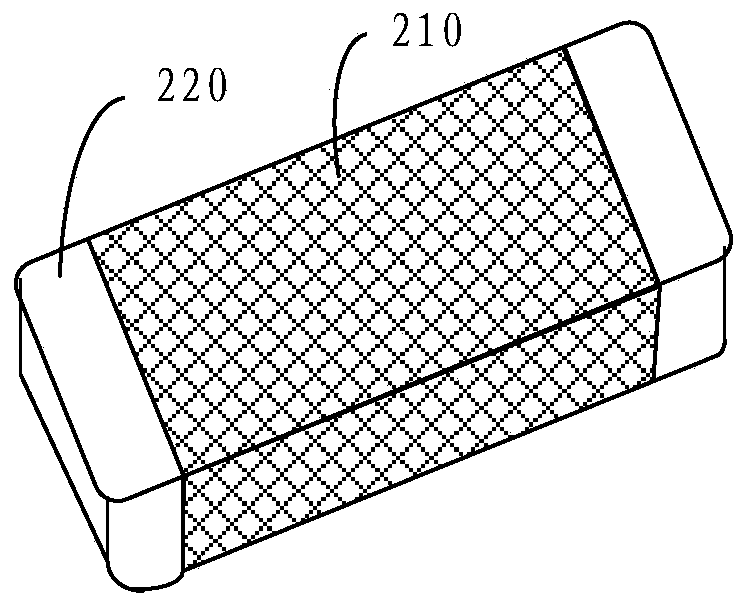

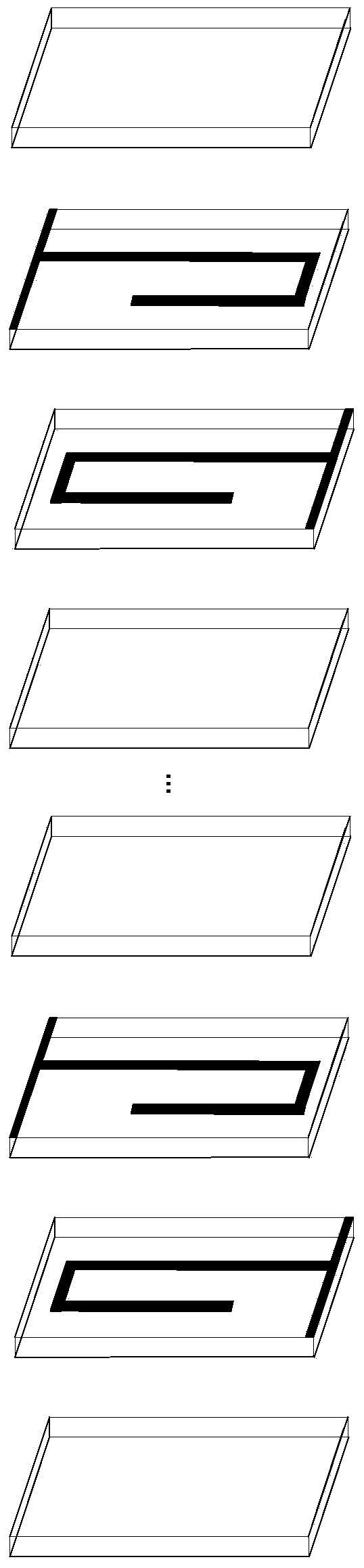

[0016] Please refer to figure 1 with figure 2 , are respectively an internal structure diagram and an external structure diagram of a laminated chip magnetic bead according to an embodiment. figure 1 As shown, the laminated chip magnetic bead includes a base membrane 110 , an inner electrode coil 120 , a base membrane 130 , an inner electrode coil 140 and a base membrane 150 .

[0017] In this embodiment, the base membrane 110 , the base membrane 130 and the base membrane 150 are all ferrite material membranes, which are formed by tape casting during fabrication.

[0018] A complete inner electrode coil 120 includes an inner electrode 122 and an inner electrode 124, and the inner electrode 122 and the inner electrode 124 are connected to each other through a metal conductor. The inner electrode coil 120 is located between different layers of base membranes (base membrane 110 , base membrane 130 ). Similarly, the inner electrode coil 140 includes an inner electrode 142 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com