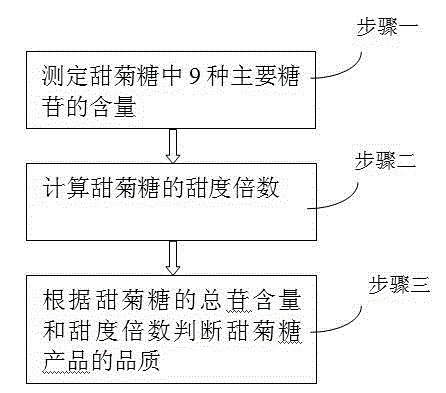

A method for evaluating the quality of stevia sugar

A stevioside quality technology, applied in the field of stevioside quality evaluation, can solve problems such as lack of objectivity, difficulty of stevioside, and complex composition of stevioside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Total glycosides 90 stevioside sample 1

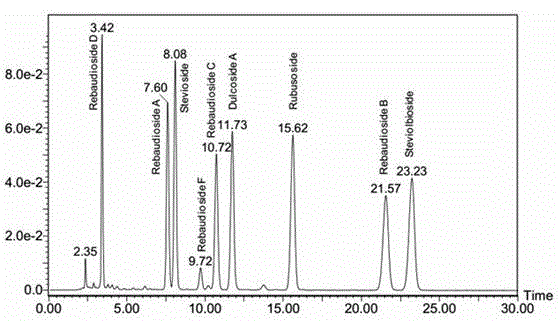

[0028] Get stevioside sample 1, detect according to JECFA standard, chromatographic conditions are as follows:

[0029] Chromatographic column: C18 column (250×4.6 mm, 5μm)

[0030] Mobile phase: acetonitrile-10mmol / L sodium phosphate (32:68), pH 2.6

[0031] Flow rate: 1ml / min

[0032] Detection wavelength: 210 nm

[0033] Column temperature: 40 o C

[0034] The results of content determination are shown in Table 2.

[0035]

[0036] Table 2 Contents of 9 kinds of glycosides in sample 1 of total glycoside 90 stevioside

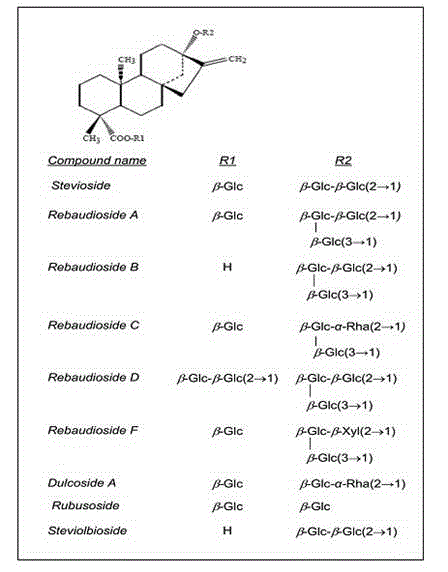

[0037] Total stevia glycosides content=64.2%+15.9%+5.8%+0.8%+0.6%+1.1%+1.5%+1.3%=91.2%

[0038] Stevia sweetness multiple = 64.2%×300+15.9%×400+5.8%×50+0.8%×200+0.6%×50

[0039] +1.1%×10+1.5%×50+1.3%×150=263.8

Embodiment 2

[0041] Total glycosides 90 stevioside sample 2

[0042] Assay method is the same as example 1, and the results are shown in Table 3.

[0043]

[0044] Table 3 Contents of 9 kinds of glycosides in sample 2 of total glycoside 90 stevioside

[0045] Total stevia glycosides content=22.9%+60.4%+0.8%+3.5%+1.2%+0.3%+0.5%+1.3%=90.9%

[0046] Stevia sweetness multiple=22.9%×300+60.4%×400+0.8%×10+3.5%×50+1.2%×200+0.3%×

[0047] 10+0.5%×50+1.3%×150=316.8

Embodiment 3

[0049] Total glycoside 95 stevioside sample

[0050] Assay method is the same as example 1, and the results are shown in Table 4.

[0051]

[0052] Table 4 Contents of 9 glycosides in total glycoside 95 stevioside samples

[0053] Total stevia glycosides content=50.8%+28.3%+1.1%+12.5%+1.3%+0.2%+0.5%+0.7%=95.4%

[0054] Stevia sweetness multiple=50.8%×300+28.3%×400+1.1%×10+12.5%×50+1.3%×200+0.2%×

[0055] 50+0.5%×50+0.7%×150=276

[0056] Stevia glycosides 90 and glycosides 95 series have become the most popular products in the market due to their high cost performance, and the prices of the two are quite different. Examples 1 and 2 show that although the two steviosides are of the same specification (both total glycosides 90), there is a large difference in sweetness. Examples 2 and 3 show that high-standard products (total glycosides 95) may not It is sweeter than the low specification product (total glycosides 90). According to the requirements of the national standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com