Medium-thick plate flame cutting sampling device and sampling method thereof

A technology of flame cutting and sampling device, applied in sampling device and other directions, can solve the problems of increasing production cost, inability to align the gun head, high labor intensity, etc., and achieve the effect of saving production cost, convenient and fast sampling process, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with examples.

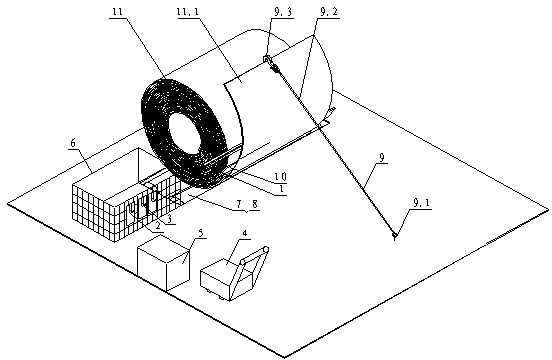

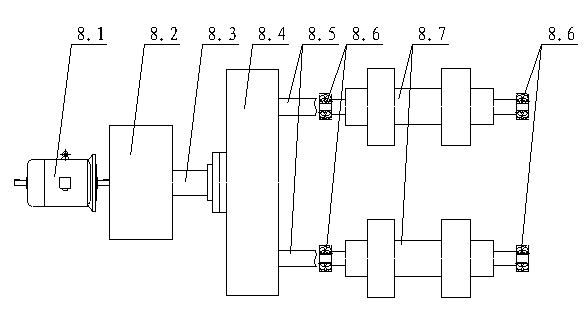

[0036] Depend on figure 1 , 2 It can be seen that the flame cutting and sampling device for medium and thick plates includes a driving car, a flame gun 1, an air wrench 2, a pneumatic packing machine 3, a sampling trolley 4 and a storage box 5, and the device also includes a set on the bottom surface of the sampling station. Pit 7, a ground roller 8 for supporting and rotating steel coils is set in the pit, and a drawstring wire rope 9 is set on the ground on one side of the pit to be perpendicular to the axis of the ground roller; a guardrail 6 and a baffle are set in the pit above the drive motor of the ground roller (not marked in the figure), flame guns, pneumatic wrenches and pneumatic balers are hung around the guardrail, and the baffle is matched with the pit to ensure that the gap between the ground roller and the ground roller does not hinder the free rotation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com