Motor vehicle headlamp

A technology for headlights and motor vehicles, which is applied to motor vehicles, road vehicles, lighting devices, etc., can solve problems such as unsightly appearance and short lighting distance, and achieve the effects of beautiful appearance, long lighting distance, and increased luminous flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

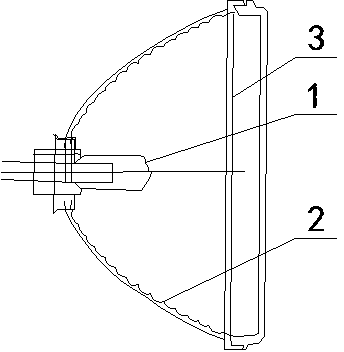

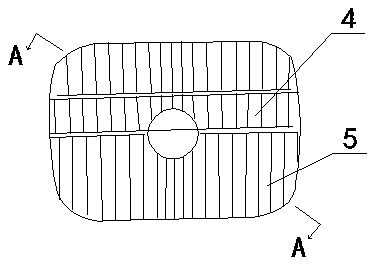

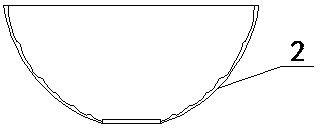

[0014] Specific embodiment 1: as figure 1 , 2, and 3, the headlight is composed of a bulb 1, a lamp body 2, and a lampshade 3, the lampshade 3 is a plane, and the inner surface of the lamp body 2 is composed of an upper reflective surface 4 and a lower reflective surface 5, and the reflective surfaces are all composed of a common The parabolic units of the main optical axis are connected, and the upper reflective surface is composed of upper and lower reflective surfaces. Headlights with such a structure, when low beam, can rely on the upper reflector to evenly illuminate the light emitted by the light source on the front side of the car, and will not cause glare to the other driver; Irradiate to the distance, in line with the requirements of the national standard GB4599-84.

Embodiment 2

[0015] Example 2: as figure 1 , 4, and 5, the headlight is composed of a bulb 1, a lamp body 2, and a lampshade 3. The lampshade 3 is a plane, and the inner surface of the lamp body 2 is composed of an upper reflective surface 4 and a lower reflective surface 5. The reflective surfaces are all composed of a common The parabolic units of the main optical axis are connected, and the upper reflective surface is composed of left and right reflective surfaces. The left and right reflective surfaces form an angle of α degrees, preferably 15°C. Headlights with such a structure, when low beam, can rely on the upper reflector to evenly illuminate the light emitted by the light source on the front side of the car, and can increase the low beam irradiation distance without causing glare to the other driver: , Relying on the lower irradiation mirror to irradiate the light evenly to the distance, it also meets the requirements of the national standard GB4599-84.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com