Whole collapse preventing high and large formwork supporting system

A technology of tall formwork and support system, applied in formwork/formwork/work frame, connection parts of formwork/formwork/work frame, on-site preparation of building components, etc. The structural system is unreasonable and other problems, so as to avoid the overall collapse and facilitate the rescue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention provides an overall collapse-proof tall formwork support system. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

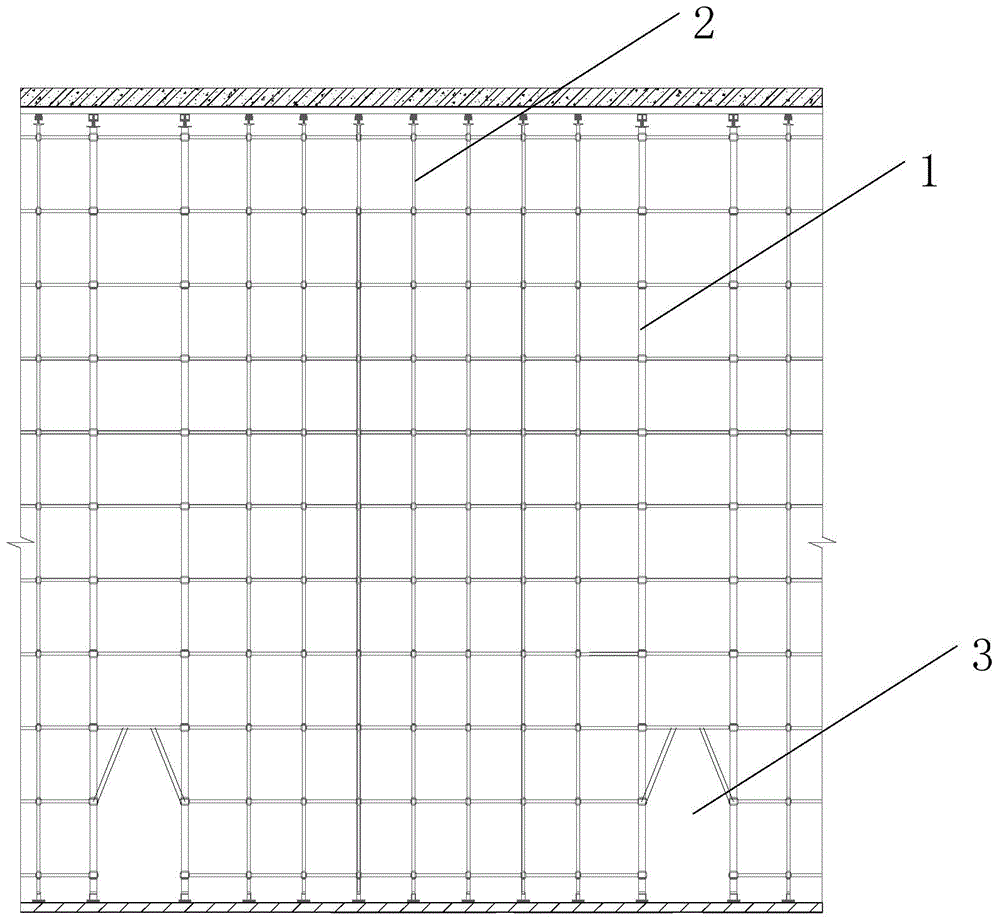

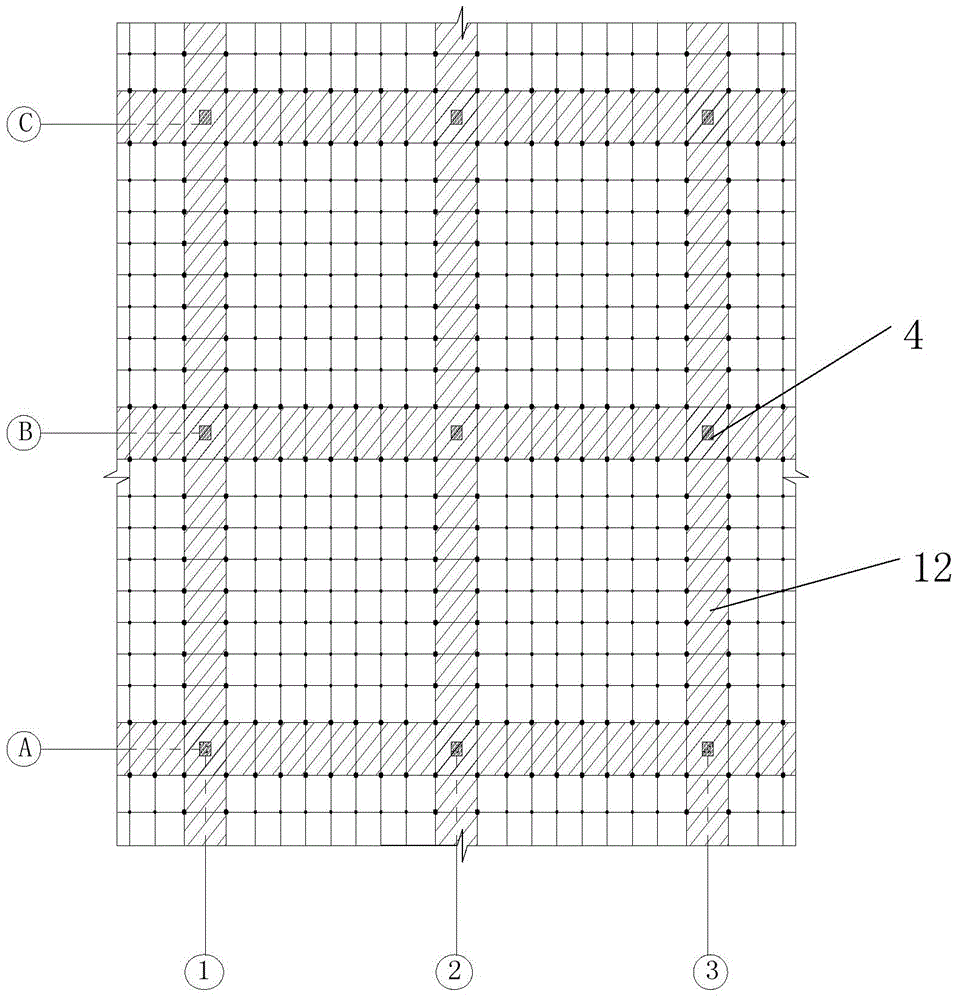

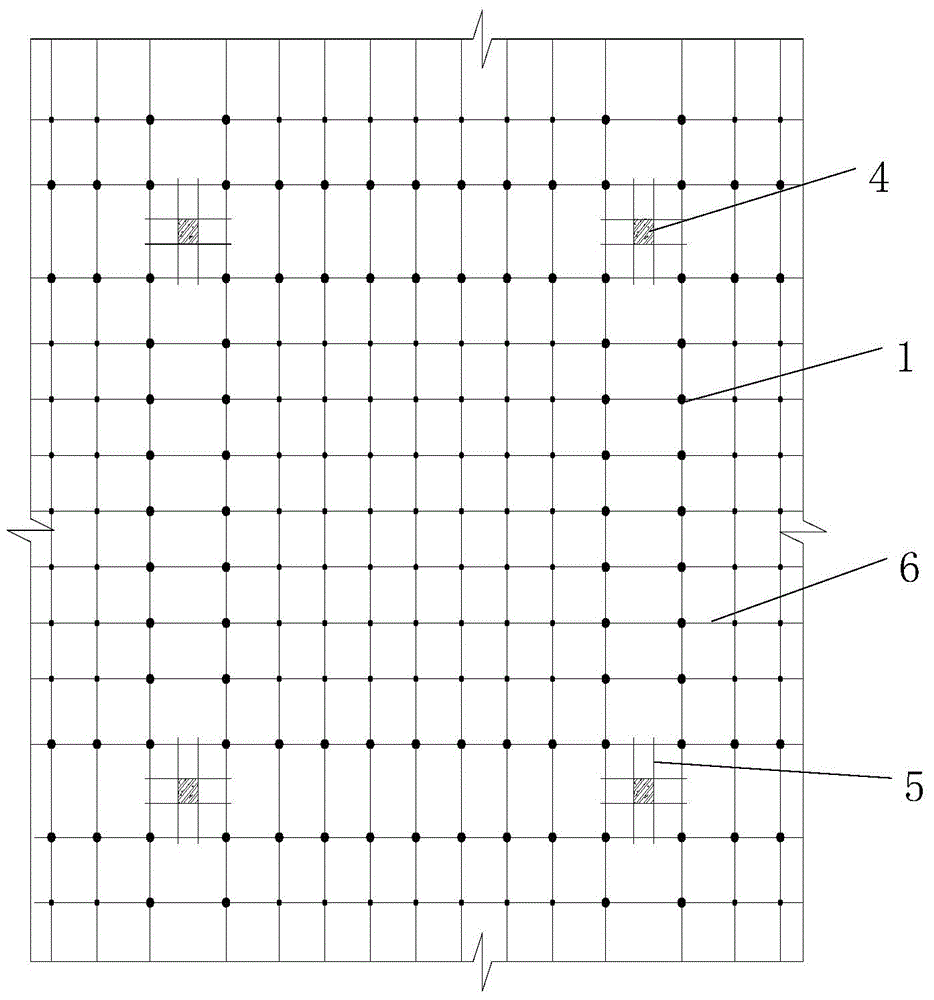

[0035] The support system consists of a dual-function structural system and a single-functional structural system, such as figure 1 , figure 2 with image 3 shown.

[0036] The dual-functional structural system includes the grid-shaped force-bearing walls 12 arranged in an orthogonal grid as the main vertical force-bearing structure, and the main keel 9, secondary keel 10 and connecting beam 11 as horizontal force-bearing components; The grid-shaped force-bearing wall is composed of two rows of thick uprights 1, crossbars 6 connecting the thick uprights 1, and vertical scissors 7 arranged on the plane of each row of thick uprights 1, forming a multi-layer structure in the vertical direction , the width of each grid-shaped force-bearing wall is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com