High-density low-detonation velocity explosive and preparation method thereof

A low-explosive, high-density technology, applied in explosives and other directions, can solve problems such as reducing the density of explosives, and achieve the effects of excellent comprehensive performance, high density and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

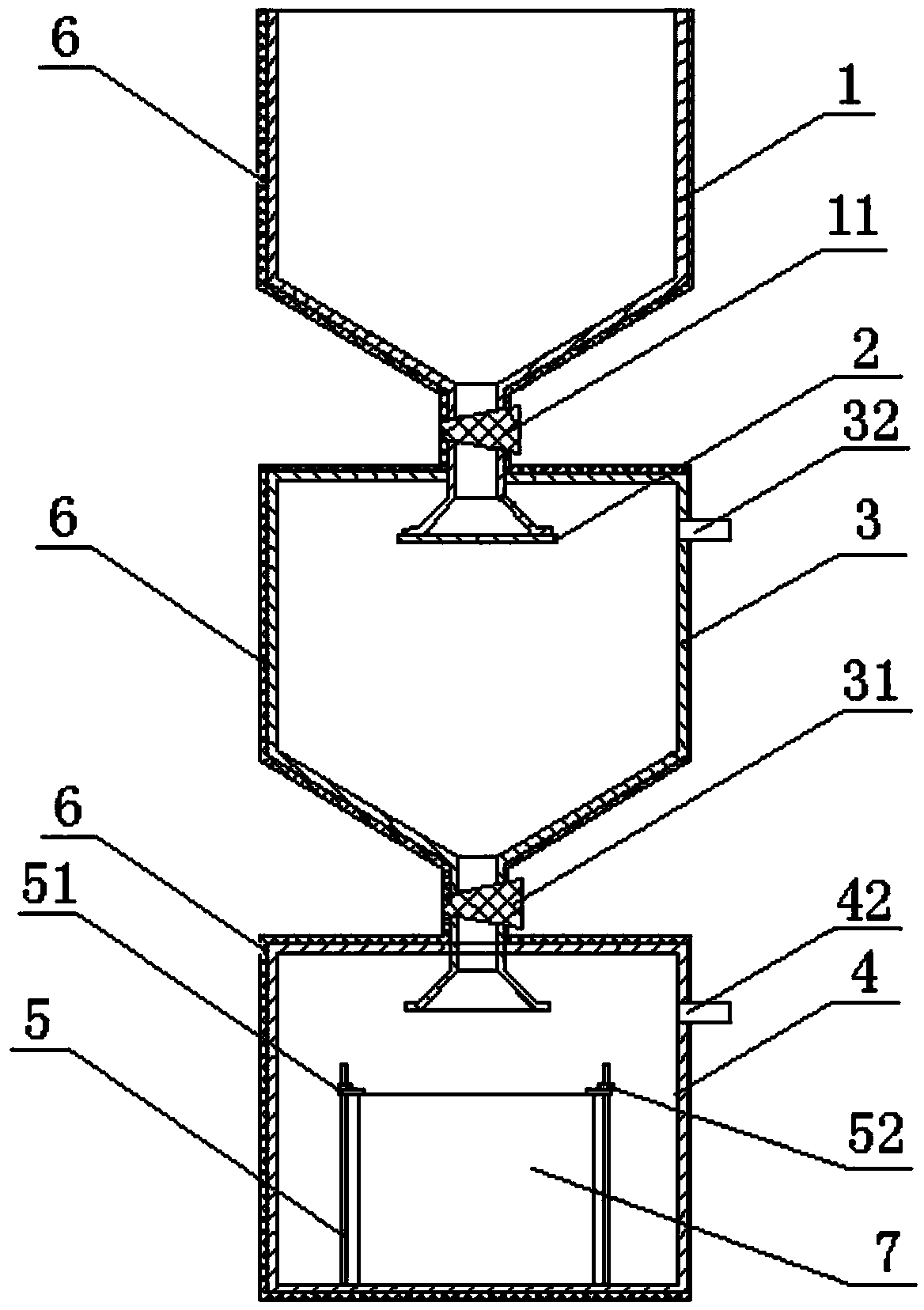

Image

Examples

Embodiment 1

[0031] The composition of the high-density low-detonation velocity explosive is: 14kg RDX (7kg of which has a particle size of 0.250mm-0.420mm, and the other 7kg has a particle size of ≤0.05mm), 65kg of barium nitrate with a particle size of 0.010mm-0.025mm, 15kg binder pentaerythritol acrolein resin, 4kg plasticizer diisooctyl sebacate and 0.7kg curing agent diethyl sulfate, its preparation process is: first adopt batch feeding and kneading mode to carry out mixing, kneading The equipment is a kneader. Knead 15kg of pentaerythritol acrolein resin and 4kg of di-octyl sebacate at 65°C for 10 minutes to obtain product I, then stop the machine to clean up the kneader blades and materials at dead ends, and then mix product I with 7kg of pellets RDX with a diameter of 0.250mm to 0.420mm was kneaded at 70°C for 8 minutes to obtain product II, and the kneader was shut down to clean up the kneader blades and materials at dead ends. Knead twice at ℃ for 12 minutes each time. After each...

Embodiment 2

[0035] The composition of the high-density low-detonation velocity explosive is: 16kg of RDX (7kg of which has a particle size of 0.250mm-0.420mm, and another 9kg of which has a particle size of ≤0.05mm), 64kg of barium nitrate with a particle size of 0.010mm-0.025mm, 16kg binder pentaerythritol acrolein resin, 5kg plasticizer diethyl phthalate and 0.6kg curing agent benzene methanesulfonic acid, its preparation process is: first adopt batch feeding and kneading mode to carry out mixing, kneading The equipment is a kneader. Knead 16kg of pentaerythritol acrolein resin and 5kg of diethyl phthalate at 70°C for 8 minutes to obtain the product I, and then mix the product I with 7kg of Hexogen with a particle size of 0.250mm to 0.420mm Kneading at 65°C for 10 minutes to obtain product II, then kneading product II with 9kg of Hexogen with a particle size of ≤0.05mm at 70°C twice for 10 minutes each time to obtain product III, and finally mixing product III with 0.6kg of benzidine Su...

Embodiment 3

[0037]The composition of the high-density low-detonation-velocity explosive is: 15kg RDX (8.25kg of which has a particle size of 0.250mm to 0.420mm, and the other 6.75kg has a particle size of ≤0.05mm), 66kg of nitric acid with a particle size of 0.010mm to 0.025mm Barium, 15.5kg binder pentaerythritol acrolein resin, 4.5kg plasticizer diethyl phthalate and 0.5kg curing agent benzene methanesulfonic acid, its preparation process is: first adopt batch feeding and kneading mode to mix The kneading equipment is a kneader. Knead 15.5kg of pentaerythritol acrolein resin and 4.5kg of diethyl phthalate at 68°C for 9 minutes to obtain product I, and then mix product I with 8.25kg of particle size of 0.250mm~ 0.420mm RDX was kneaded at 70°C for 8 minutes to obtain product II, then product II was kneaded with 6.75kg RDX at 66°C twice for 8 minutes each time to obtain product III, and finally Knead product III and 0.5kg benzene methanesulfonic acid twice at 65°C for 9 minutes each time t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com