An automatic tube loading machine and tube loading method for a medicinal glass bottle making machine

A glass tube and bottle making machine technology, applied in glass forming, glass manufacturing equipment, glass reshaping, etc., can solve the problems of low efficiency of feeding and feeding tubes, increase labor costs, reduce production efficiency, etc., and achieve reduction Labor costs, improved worker safety, and the effects of increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and the pipe-up method, but it is not intended to limit the protection scope of the present invention.

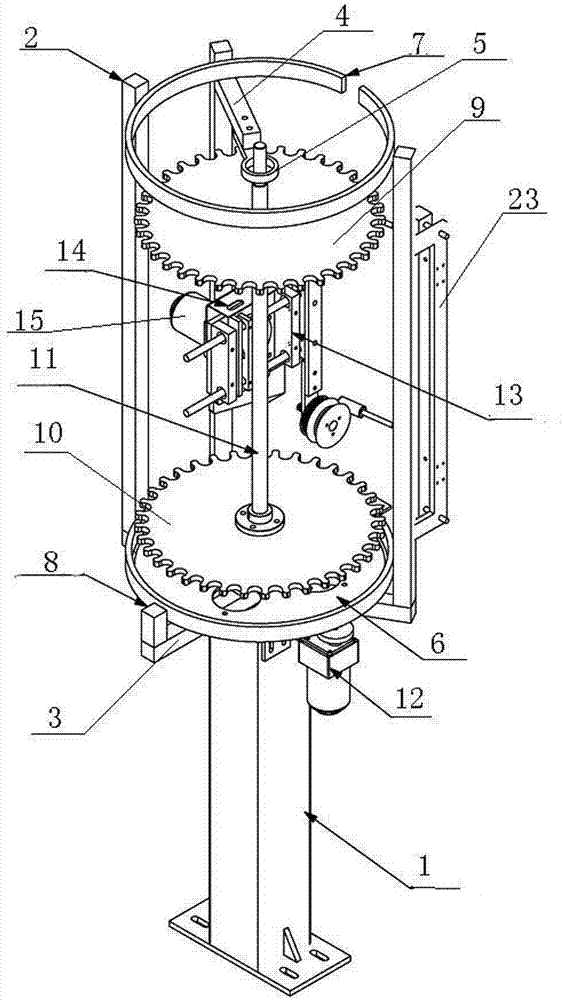

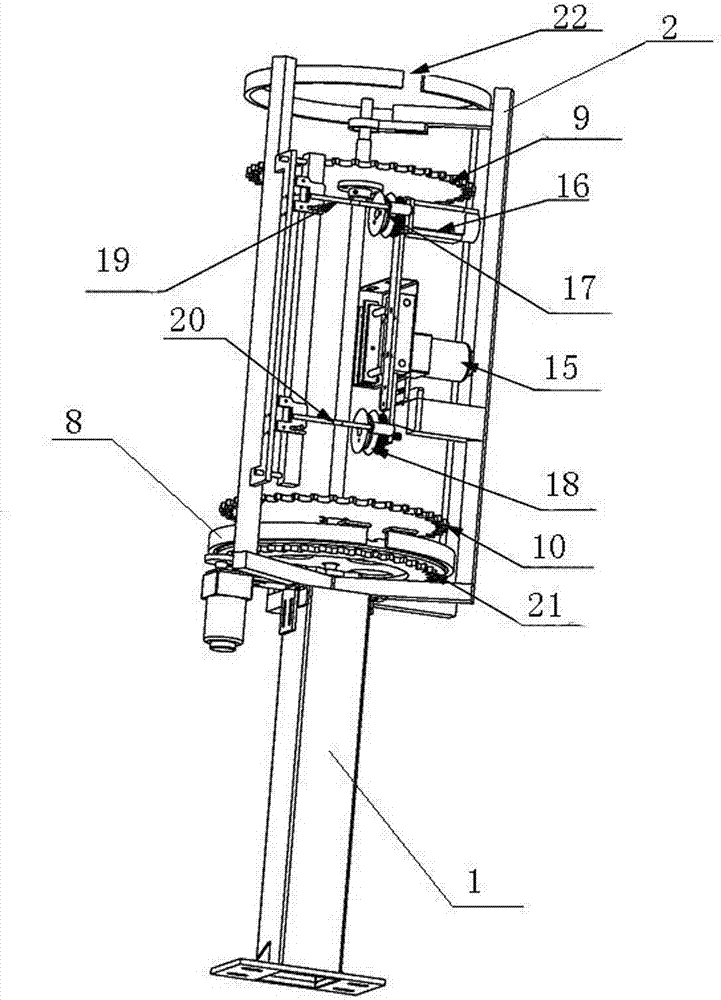

[0032] Such as figure 1 with 2 As shown, a tube loading machine for a medicinal glass bottle making machine, including a tube storage mechanism and a tube delivery mechanism,

[0033] The tube storage mechanism includes a glass tube rack, a glass tube chassis 6 arranged at the bottom of the glass tube rack, a lower annular ring 8 of the glass tube rack arranged above the glass tube chassis 6 and an upper annular ring 7 of the glass tube rack arranged on the top of the glass tube rack , the center of the glass tube rack is provided with a glass tube rotating column 11, and the glass tube chassis 6 is rotatably connected to the bottom of the glass tube rotating column 11;

[0034] The tube delivery mechanism includes a tube delivery trolley 13, a tube deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com