Tool for processing cylindrical workpiece

A technology of solid workpieces and cylinders, which is applied in the field of processing tooling for cylindrical slender and thin-walled parts, can solve the problems of many processes and long auxiliary time, so as to reduce operators, reduce the number of clamping times and auxiliary time, Structural light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

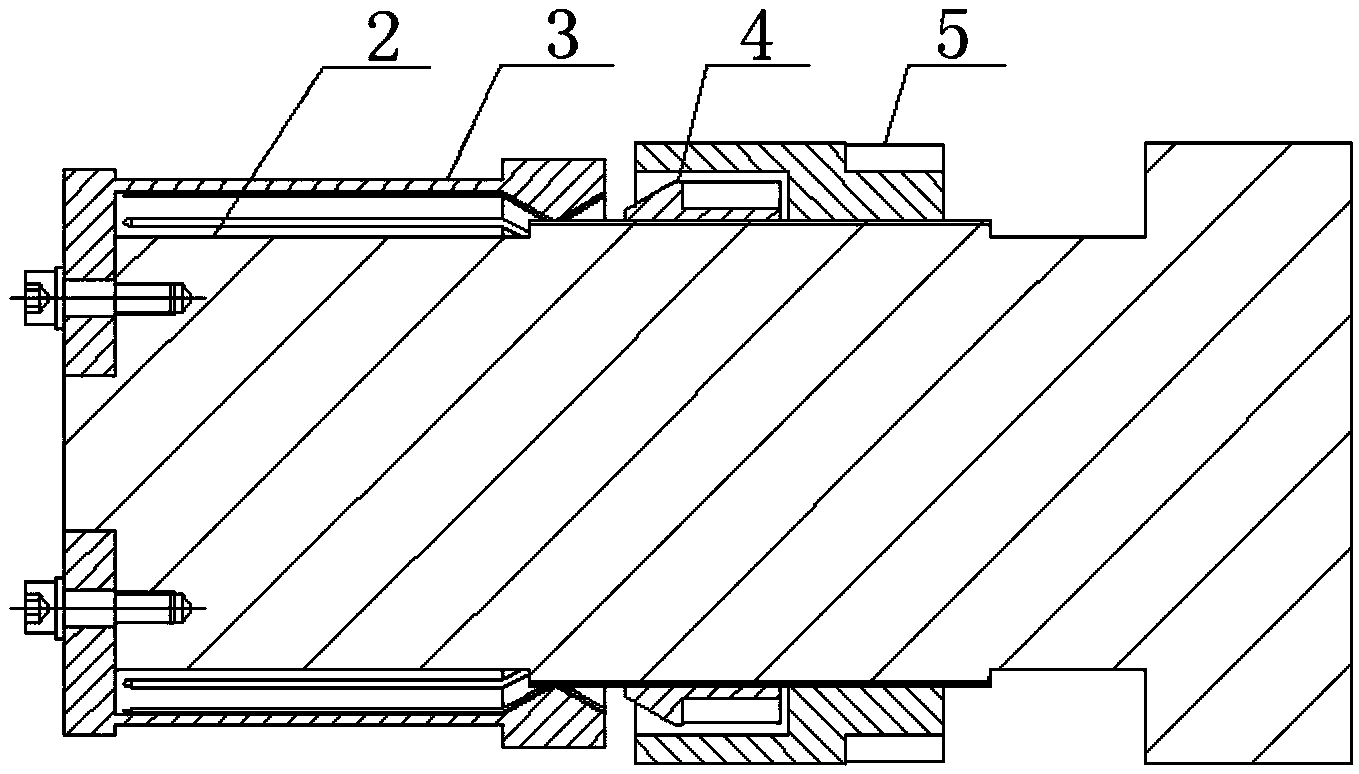

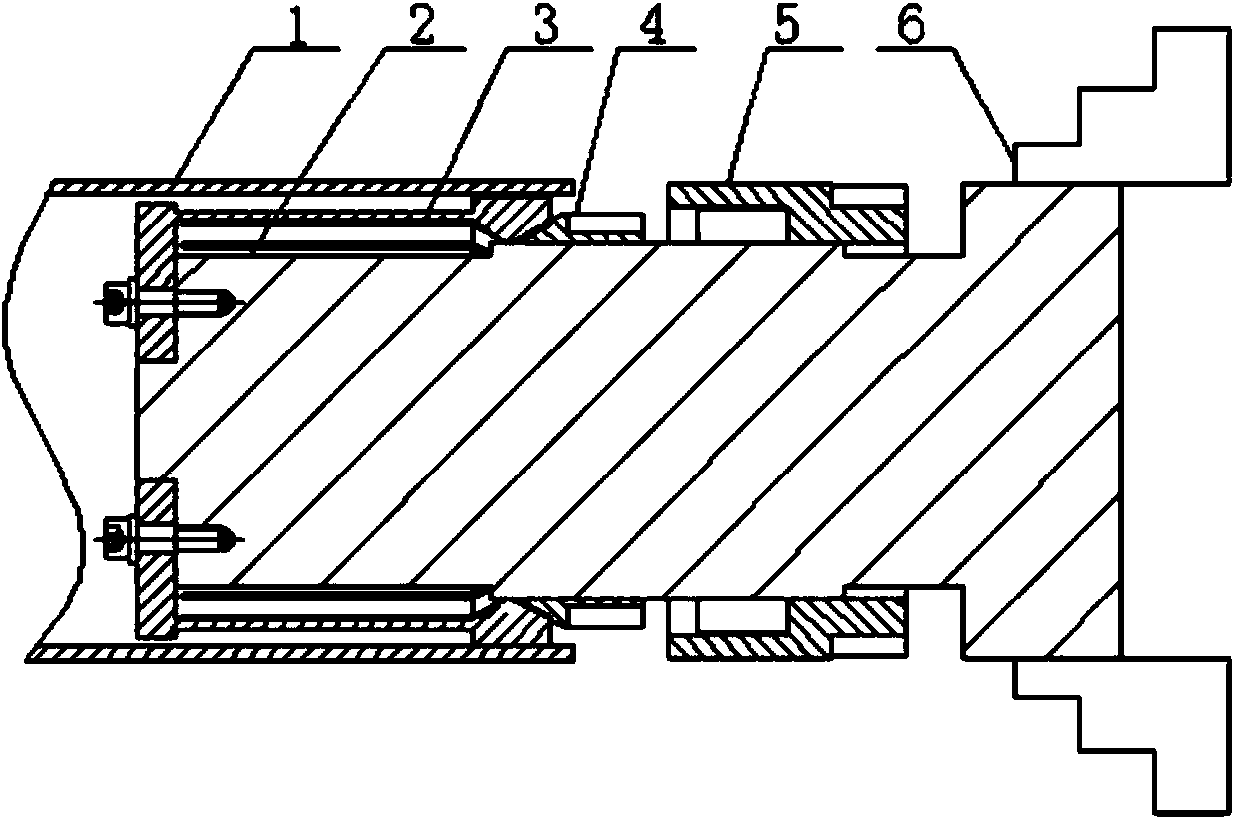

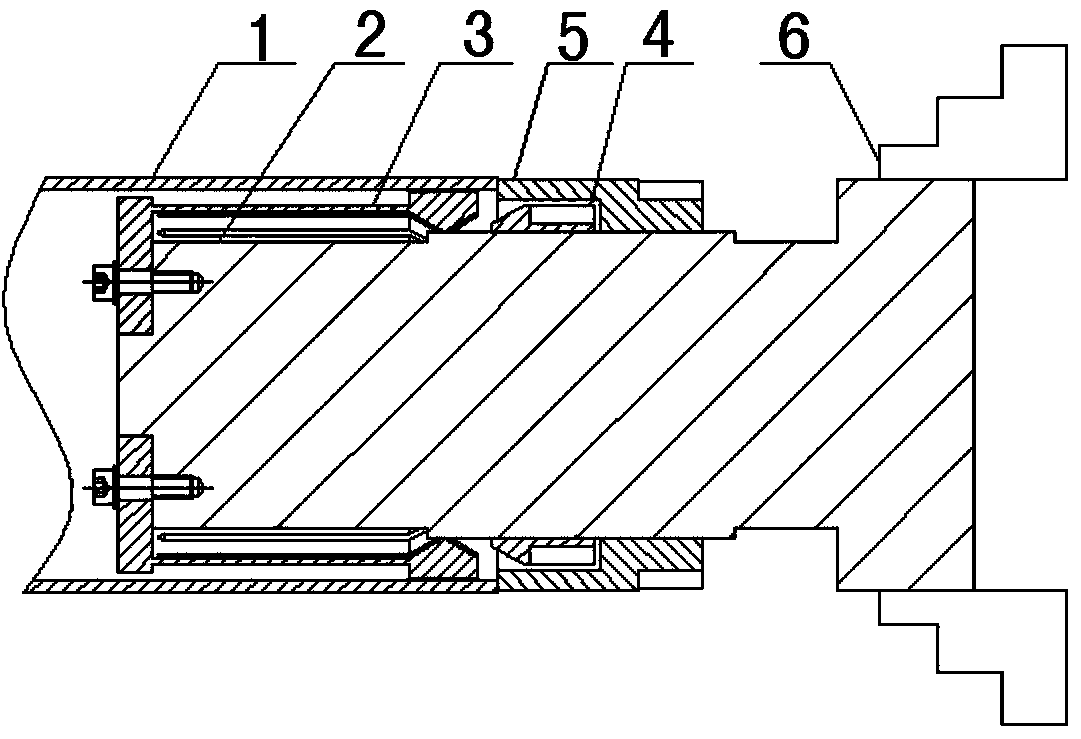

[0021] This embodiment is a thin-walled elongated cylindrical batch production processing tool.

[0022] In the present embodiment, the processed workpiece is a 30CrMnSiA thin-walled slender cylinder with an aspect ratio of 1900 / 125=15.2. The outer diameter of the workpiece is 125mm, and the inner diameter is 117mm. The total length of the cylinder is 1900mm. The ratio of the outer diameter to the wall thickness It is 125 / 2=62.5. The cylinder is formed by spinning. It is necessary to machine the annular belts of the two ends of the cylinder, wherein the axial length of the annular belt at one end is 60mm, and the axial length of the annular belt at the other end is 120mm, and the coaxiality of the annular belts at both ends is required to be 0.08; 2. Processing The ends of the cylinder. Since the cylinder has a large length-to-diameter ratio and high dimensional accuracy, it is necessary to effectively control product deformation and ensure processing efficiency.

[0023] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com