A connecting and folding belt correcting and bending mechanism

A technology of bending mechanism and shape correction, which is applied in the field of cold stamping and bending, can solve the problems of increasing mold manufacturing cost and maintenance cost, complicated bending process, and unguaranteed accuracy, so as to improve bending work efficiency and save replacement Mold time and the effect of shortening the time for mold replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

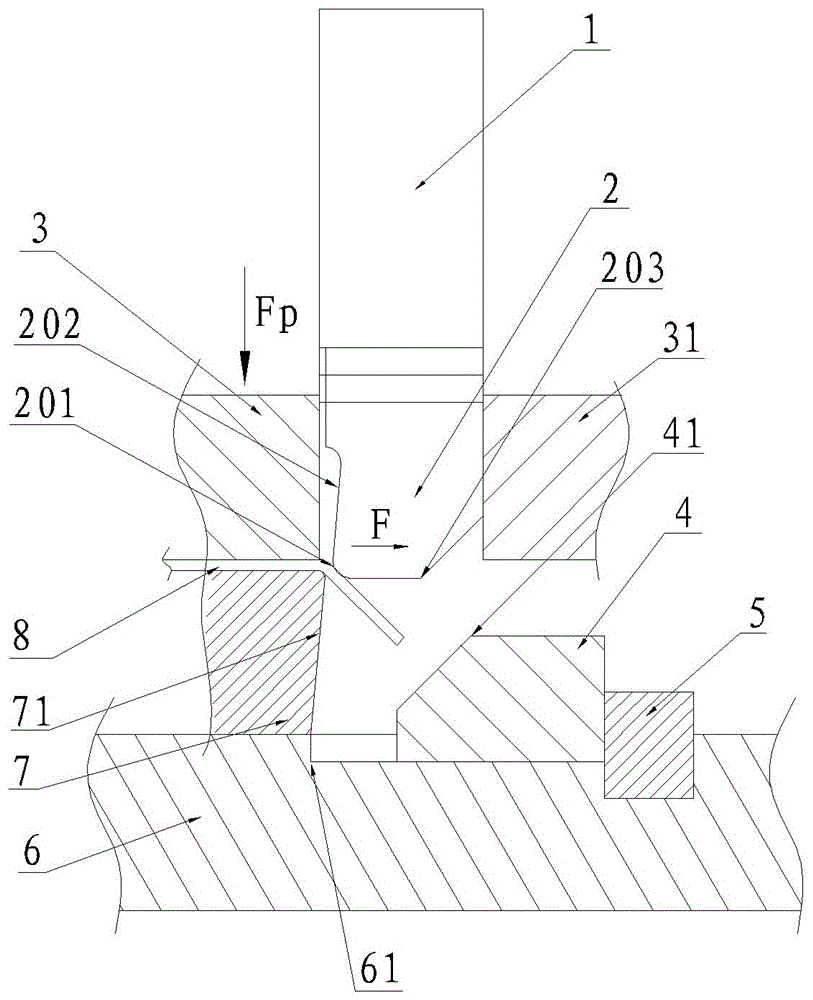

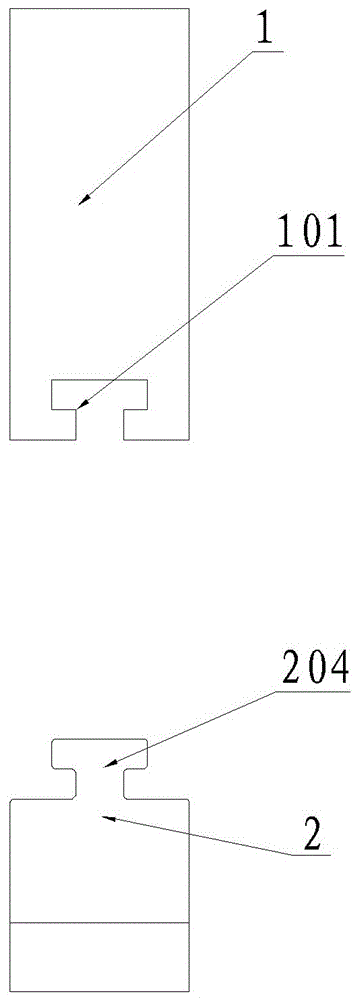

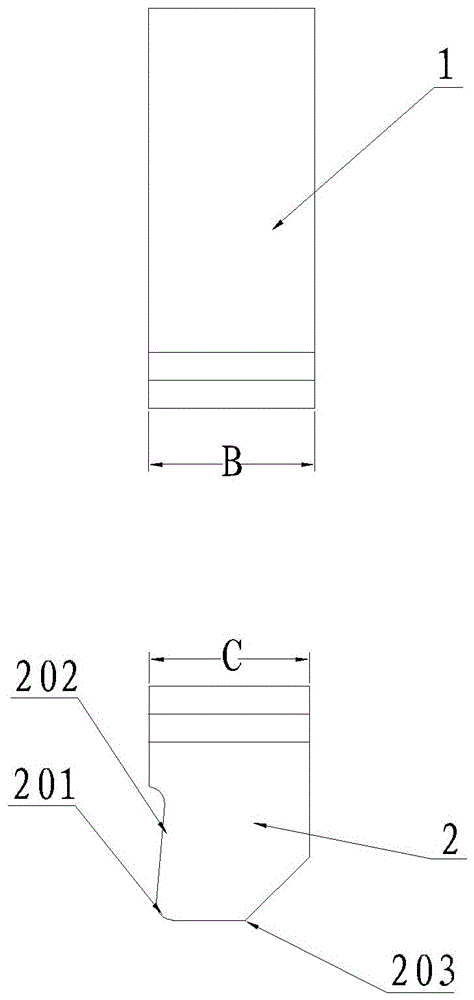

[0042] like figure 1 , Figure 4 and Figure 5 As shown in , it is a schematic diagram of the cold stamping process of a simple part using a set of fixed bending punches and movable bending punches, where figure 1 for figure 1 It is the state when the movable bending punch of an embodiment of the present invention has just touched the product. At this time, the movable bending punch 2 is under the action of the friction force F with the workpiece 8 to be processed along the 45 When the fixed bending punch 1 touches the 45-degree inclined surface of the workpiece 8 to be processed, the fixed bending punch 1 starts to stamp the workpiece 8 to 90-degree bending state; Figure 4 It is a schematic diagram of the structure of the movable bending punch of an embodiment of the present invention, where the weight of the movable bending punch becomes Fa. At this time, the 90-degree bending ends, and the 90-degree shape correction begins to prepare; Figure 5 It is a bending state...

Embodiment 2

[0045] In order to satisfy as Figure 10 For the part to be bent with two ears shown, a pair of through holes 9 are opened on the ears 10 of the part to be bent with two ears. The design requires that the coaxiality of the pair of through holes 9 on the two ears should not be greater than 0.2, and the material is SPFH540 , thickness T=2.0, need mass production.

[0046] Process analysis: The material has large springback, and it is difficult to bend with corners. The opening size requires 8+0.2, the tolerance is small, and the stability of the bending angle is the key factor affecting the coaxial 0.2 of the two holes on the side.

[0047] Process plan: continuous mold, two steps of bending, the first step adopts the existing technology to bend 45 degrees, and the second step uses the continuous folding belt shaping and bending mechanism of the present invention, such as Figure 11 Shown is a schematic diagram of the continuous folding belt shaping structure of the double-eare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com