Hybrid magnetic-circuit torquer and flexible gyroscope comprising the same

A flexible gyroscope and hybrid magnetic circuit technology, which is applied in the direction of rotating gyroscopes, electrical components, electromechanical devices, etc., can solve the problems of large dynamics and high precision, and it is difficult to meet the requirements of fast use of moving carriers, etc., to achieve the realization of work The effect of rapidity requirements, improvement of successive stability accuracy, and reduction of the influence of magnetic flux leakage torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

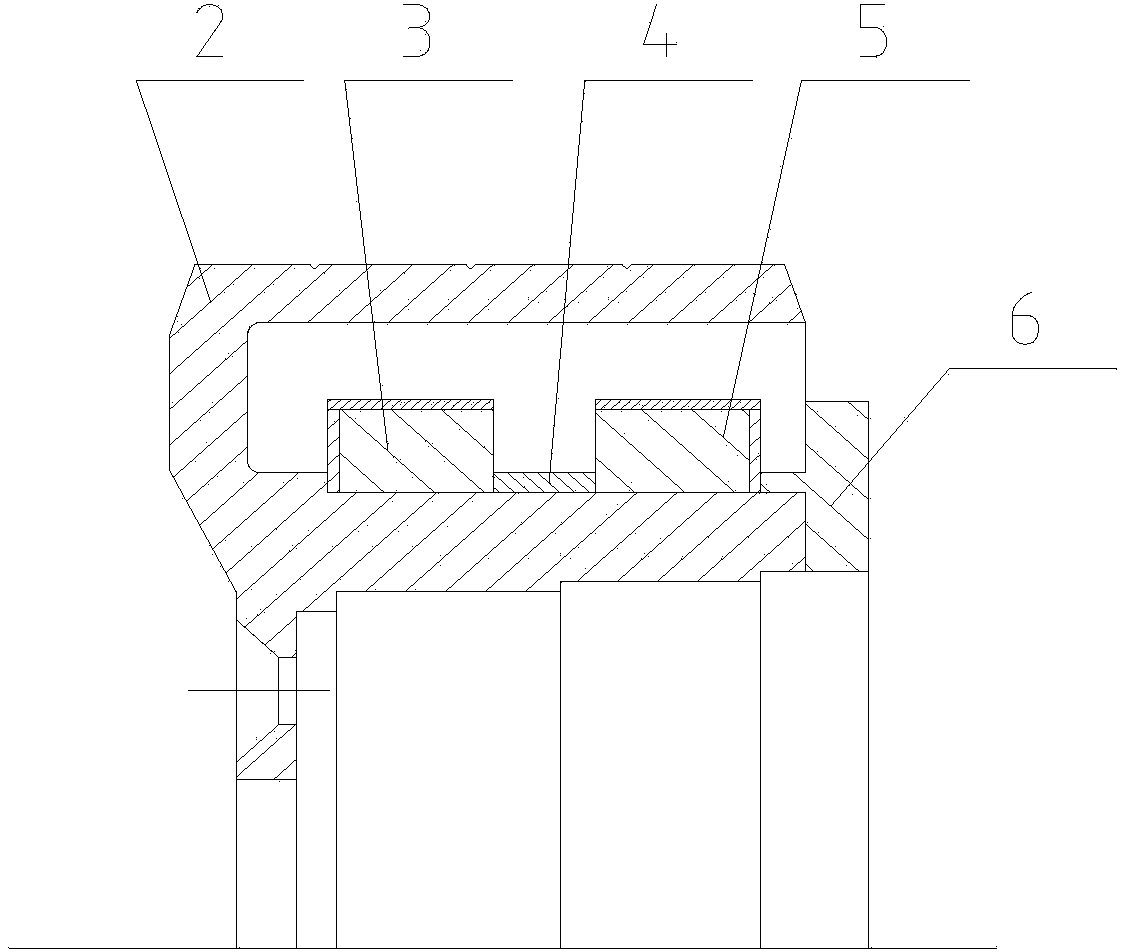

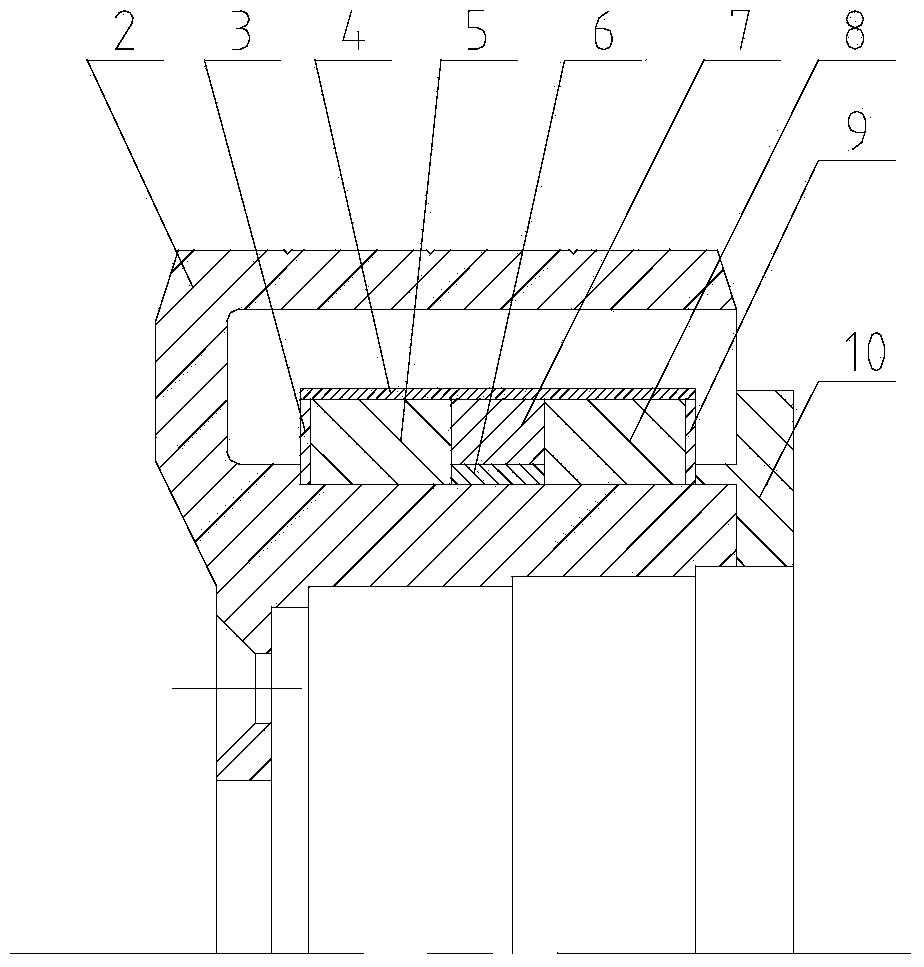

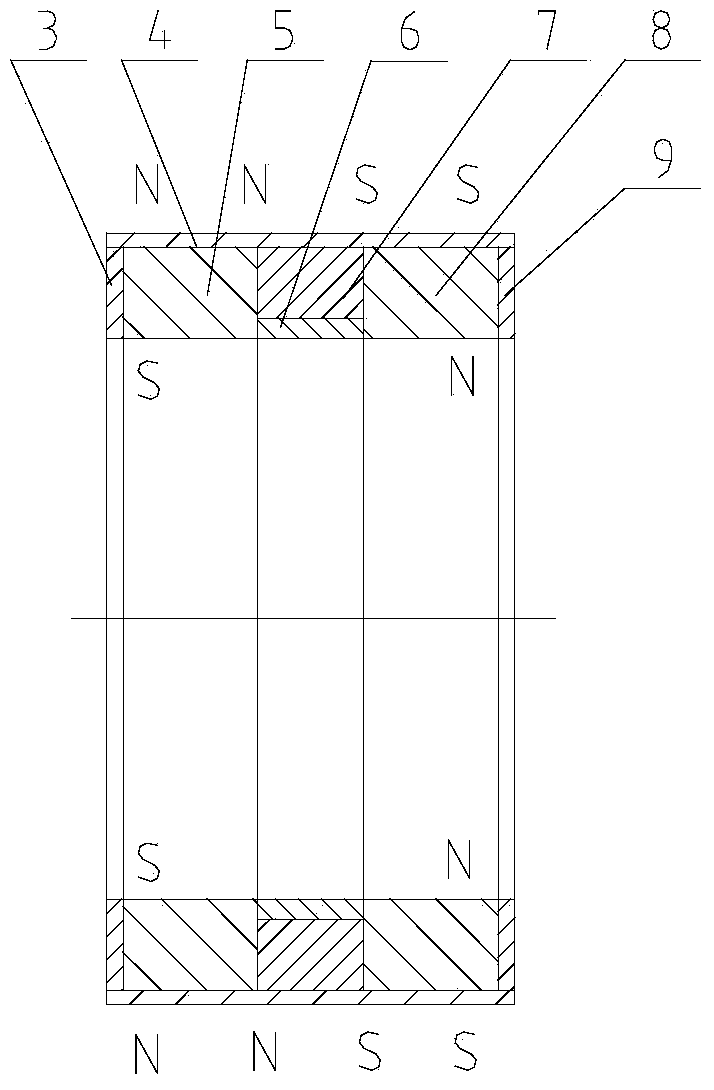

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] According to the precession principle of the flexible gyroscope, the tracking angular rate ω of the gyroscope is:

[0029] ω=M / H………………………………………(1)

[0030] In the formula (1): M—the electromagnetic control torque produced by the torque device:

[0031] H—gyroscope angular momentum;

[0032] ω—tracking angular rate.

[0033] In order to improve the tracking angular rate ω of the gyroscope and achieve a large dynamic measurement range, it can be carried out from two aspects. One is to increase the electromagnetic torque M of the torque device, and the other is to reduce the angular momentum H of the gyroscope. The relationship between the electromagnetic torque M and the coil current is:

[0034] m 电 =k M .i………………………………………(2)

[0035] In formula (2): M 电 - the electromagnetic torque generated by the energized coil under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com