A method and device for adjusting parameters of an EPS controller

A controller and parameter adjustment technology, applied in control/adjustment systems, program control, computer control, etc., can solve problems such as inability to parse data structures, not supporting MCU often looking at variable values, and limited debugging methods in the integrated compilation and debugging environment. Achieve the effect of integrating resources and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

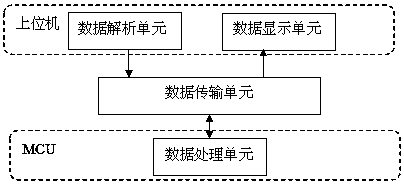

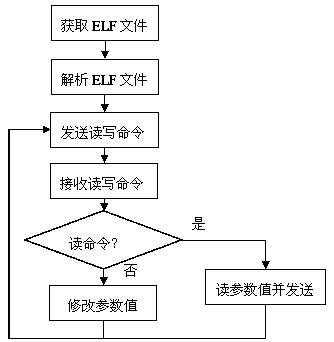

[0036] see Figure 1 ~ Figure 2 A parameter adjustment method of an EPS controller, firstly, under the integrated control environment provided by the MCU in the EPS controller, compile the EPS controller program to generate an ELF (Executable and Linkable Format) object file, and then analyze the ELF object file, After the ELF target file is parsed, the parameter information to be adjusted is encapsulated into read and write commands and sent to the MCU, and the MCU parses the read and write commands to complete the parameter adjustment of the EPS controller.

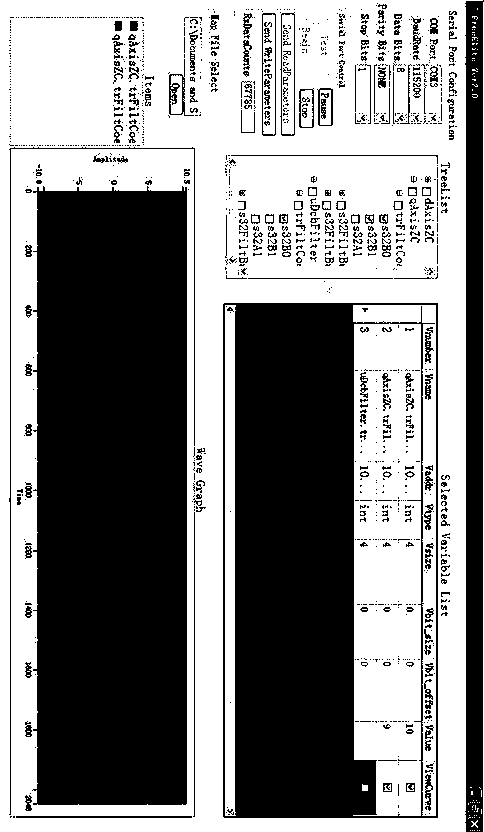

[0037] see image 3 A parameter adjustment interface for the EPS controller, including Serial port configuration: serial port configuration, Serial port control: serial port control, RxD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com