Capacitive voltage transformer live detector

A voltage transformer and capacitive technology, applied in the field of 220kV capacitive voltage transformer live detectors, can solve the problems of large primary investment, unsatisfactory overall test results, and high secondary maintenance costs, and achieve simple operation and light weight. , The effect of convenient and safe wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

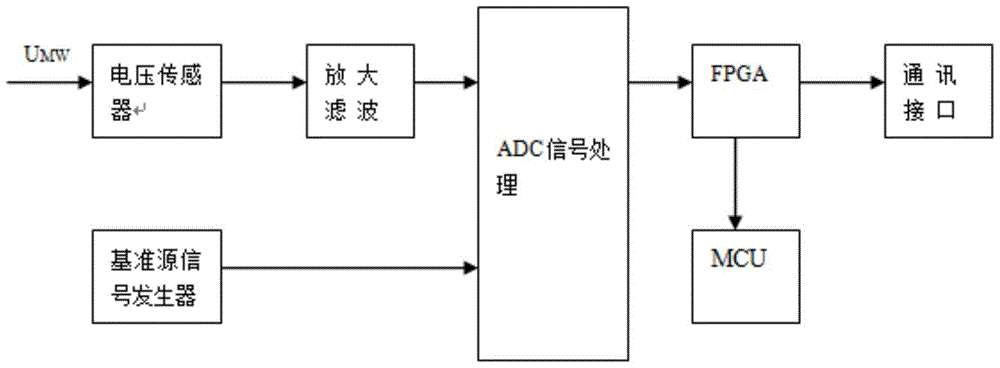

[0019] As shown in the attached figure, the CVT electrification detector includes three parts: current unit, voltage unit and notebook computer, see figure 1 . The shielded network cable is used between the units for signal transmission between the units, the shielded cable is used to power the voltage unit, and the 485 bus and USB to 485 serial port are used to realize the information transmission between the current and voltage units and the computer.

[0020] Voltage unit: used to measure bus PT voltage U MW , U MW After the voltage sensor is amplified and filtered, the reference signal generated by the reference source signal generator is processed by the ADC signal, and the analog signal is converted into a digital signal that can be recognized by the machine, and then input to the microcontroller (MCU) through the field programmable gate array (FPGA) It is stored in the computer, communicates with the current unit through the FPGA and the communication interface, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com