Integrated hydrogen sensor made from mixed graphene film, noble metal particles and metallic oxide materials and preparation method thereof

A graphene film and sensor technology, applied in the direction of material resistance, can solve the problem of hydrogen selectivity and other problems, and achieve the effect of improving sensitivity

Inactive Publication Date: 2014-09-10

NANJING YIDEGUAN ELECTRONICS TECH +1

View PDF5 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, while the surface modification and doping of metal oxides have improved the sensitivity of sensitive materials to hydrogen and other gases in an all-round way, they still cannot solve the selectivity of hydrogen detection, which requires new technologies to cover the selective question

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0052] Preparation of Gra-Pd-ZnO thin film hydrogen sensor, the specific steps are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

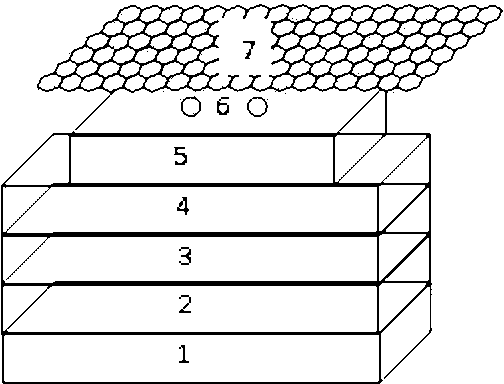

The invention discloses an integrated hydrogen sensor made from mixed graphene film, noble metal particles and metallic oxide materials and a preparation method of the integrated hydrogen sensor. The sensor comprises a substrate, a heating electrode, a heat-conducting insulation layer and a detection electrode; the heating electrode is placed on the substrate; the heat-conducting insulation layer is placed between the heating electrode and the detection electrode and further the sensor further comprises a metallic oxide film deposited on the detection electrode, the noble metal particles deposited on the metallic oxide film, and the graphene film covers the metallic oxide film on which the noble metal particles are deposited. The noble metal particles covering the metallic oxide film are single atoms, wherein the covering rate is 0.05-100 percent, the particle size is 0.2-0.4 nanometers, and the noble metal particles are randomly and uniformly arranged. The metallic oxide film is 10 nanometers to 2 micrometers in thickness. The graphene film is 0.5-1.2 nanometers in thickness. By adopting the integrated hydrogen sensor provided by the invention, high-sensitivity and high-selectivity detection and monitoring for hydrogen can be simultaneously achieved.

Description

technical field [0001] The invention belongs to the field of gas sensors, and in particular relates to an integrated hydrogen sensor of hybrid graphene film, noble metal particles and metal oxide materials and a preparation method thereof. Background technique [0002] Hydrogen, together with solar energy and nuclear energy, is known as the three major new energy sources due to its high combustion efficiency and non-polluting products. As a new energy source, hydrogen is widely used in aviation, power and other fields; at the same time, as a reducing gas and carrier gas, hydrogen plays an extremely important role in chemical industry, electronics, medical treatment, metal smelting, especially in the field of military defense. Value. However, hydrogen molecules are small and are easy to leak during production, storage, transportation and use. Since hydrogen is colorless, odorless, explosive, and its ignition point is only 585°C, and its content in the air is in the range of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N27/12

Inventor 章伟王瑞许泳李雨桐李涛秦薇薇高志强蔡依晨杨楠徐玫瑰

Owner NANJING YIDEGUAN ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com