Maintenance method of insulation refractory material for horizontal beam of heating furnace

A technology for overhauling and maintaining horizontal beams, which is applied in the field of overhauling and maintaining horizontal beams for heating furnaces. It can solve the problems of high maintenance costs and long maintenance times for horizontal beams for heat-insulating and refractory materials, reducing labor costs and reducing spare parts costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

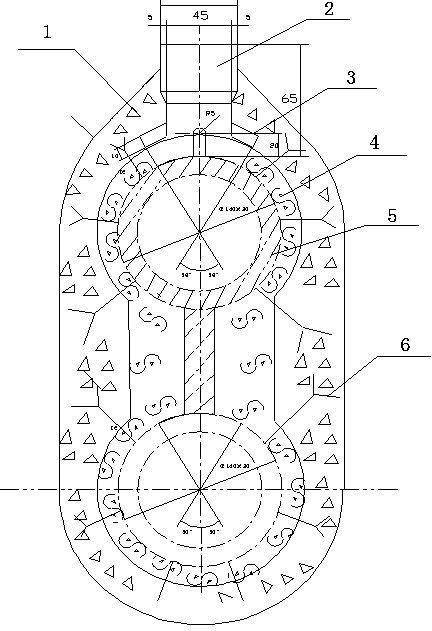

[0029] The specific implementation method is:

[0030] (1) Preparation of spare parts and preparation of materials:

[0031] According to the preparations before the repair and repair of the horizontal beam insulation and refractory materials of the hot-rolled walking heating furnace: the equipment that needs to be manufactured is:

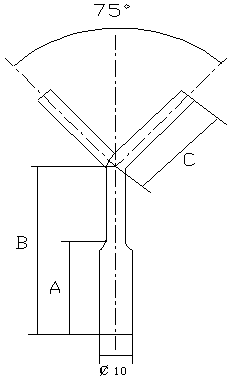

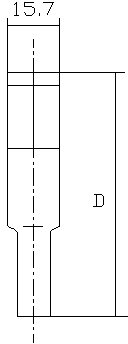

[0032] 1) Y-shaped anchor hook, such as figure 1 as shown,

[0033] The Y-type anchor hook is made of round steel with a diameter of 10mm, and the material is Cr25Ni20; the Y-type split angle is 75°±5°. The three different sizes are:

[0034]

[0035] Among them, the height dimension accuracy is ≤±1mm, and the unevenness is ≤1mm.

[0036] 2) The materials required for procurement are: directly purchased plastic repair materials, stainless steel welding rods, and 20mm thick high-aluminum fiber felt.

[0037] Among them, the plastic repair material is high-aluminum plastic AL78, and its performance meets the material standard GB / T6900-1986....

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com