A self-lubricating balanced rotating partition with double tie rods

A rotating baffle, self-lubricating technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., to achieve the effect of good effect, flexible rotation and low pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

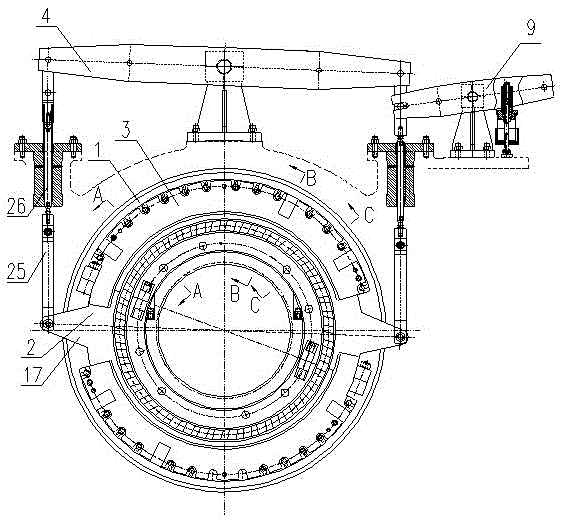

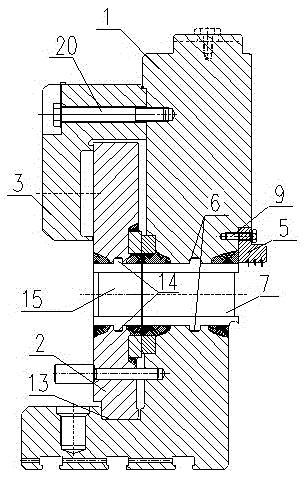

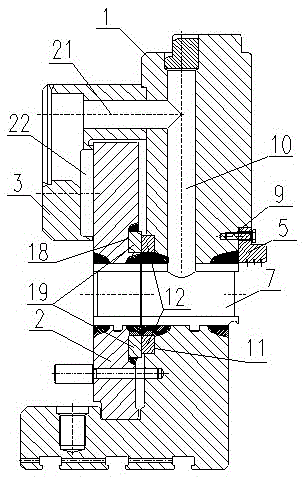

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the double tie rod self-lubricating balanced rotating diaphragm described in this embodiment includes a diaphragm body 1, a rotating ring 2, a steam balance chamber cover ring 3, an adjusting connecting rod 4 and a steam seal body 5, and the diaphragm The body 1 is divided into upper and lower semicircular structures, which are detachably connected by bolts; the partition body 1 has an annular passage along a circumferential line, and a first steam vane ring groove 6 is opened on the inner circumferential surface of the annular passage. The first cascade 7 is installed in the first steam vane annular groove 6, and the first cascade 7 is composed of a plurality of first steam passage windows 8 of the same size and evenly distributed. There is a steam seal body 5 on the top; there are a number of first balance chambers 22 channels 10 in the radial direction on the outer ring of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com