Construction method of hoisting prefabricated frame structure components

A frame structure and prefabricated assembly technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of inability to meet the construction requirements of prefabricated components, the inability to obtain economic benefits, and complicated hoisting steps, so as to achieve simple and fast hoisting construction , wide coverage, the effect of ensuring the quality of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

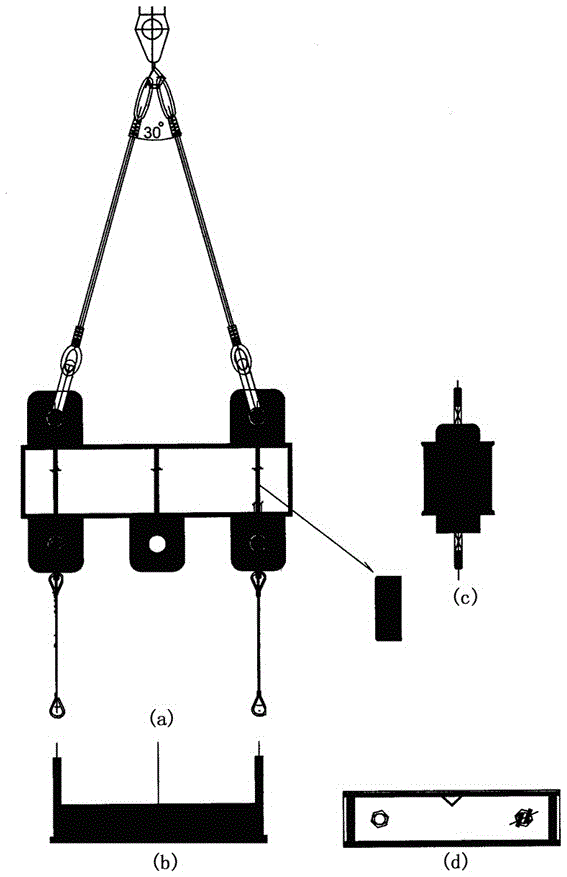

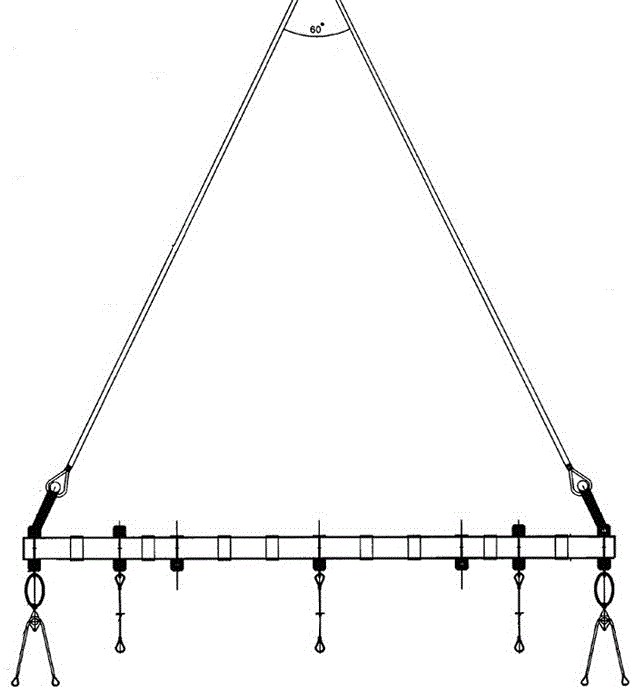

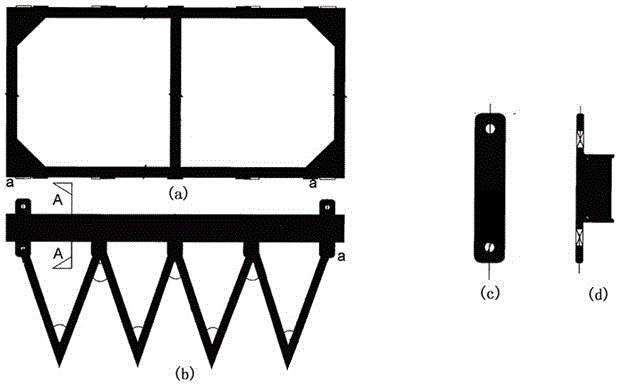

[0032] Below in conjunction with taking certain project construction as example in conjunction with accompanying drawing, the present invention is described in further detail.

[0033] Materials and equipment required by the method of the present invention: various hangers for prefabricated concrete components are made of HPB235 steel, and suspension rings are made of HPB300 steel bars that have not been cold-worked. The embedded nuts or embedded suspenders used for the hoisting of prefabricated components shall be selected according to the corresponding product standards and application technical regulations.

[0034] List of main auxiliary materials for hoisting

[0035]

[0036] Main mechanical watches required for hoisting

[0037] serial number

name

Specifications

quantity

purpose

1

500t·m

1

Prefabricated column hoisting

2

Wheeled Crane

50t

1

Prefab Assembly

3

Wheeled Crane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com