Embroidery bead feeding device and embroidery machine comprising same

A technology of feeding device and embroidery machine, applied in the direction of automatic control embroidery machine, embroidery machine, embroidery machine mechanism, etc. Bead supply method or structure and other issues to achieve the effect of solving industry problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

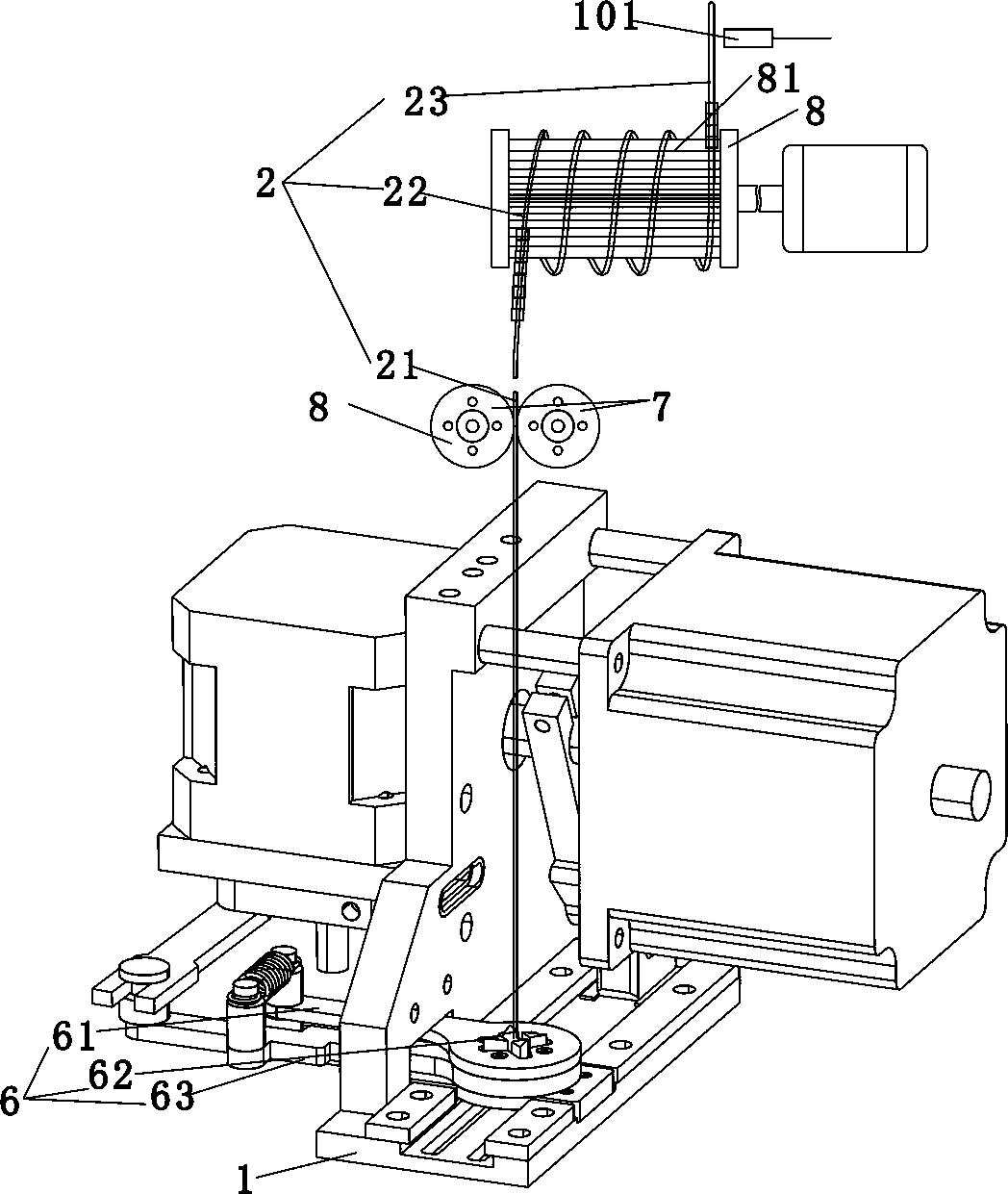

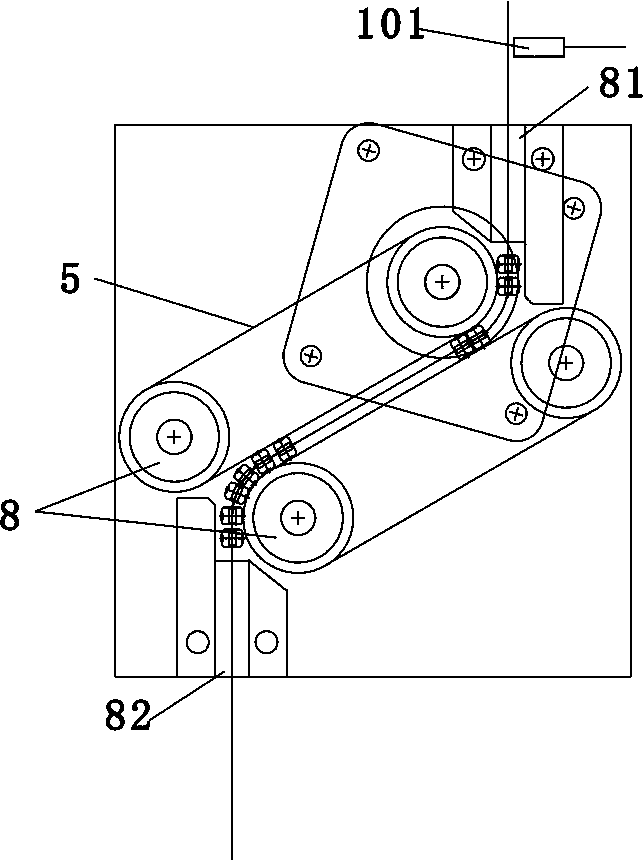

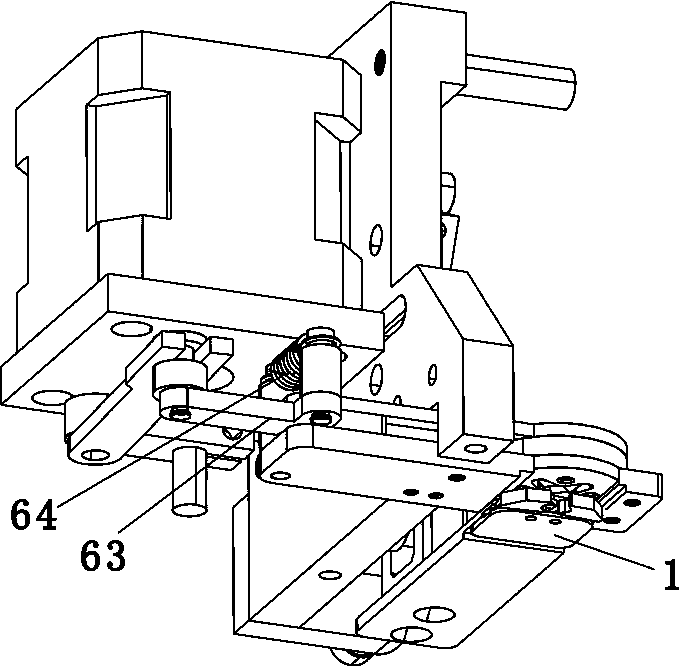

[0028] see Figure 1-12 , this implementation case includes a body (not shown in the figure), an embroidery machine head 1a, a beam 2a that can place a thread rack, and an embroidery bead feeding device is provided on the machine head 1a, and the feeding device includes sending the embroidery beads one by one to the embroidery needles of the embroidery machine The feed mechanism 1 directly below the feed mechanism 1 is suspended above the feed mechanism 1 to supply the beads to the guide rod 2 of the feed mechanism 1, and the beam 2a is suspended above the thread rack to supply the beads guide rod 2 to embroider. The bead stringing device 3a is suspended on the beam 2a with a support frame 4a for placing the bead stringing device 3a. The support frame 4a can be suspended above the beam 2a through other brackets. In this embodiment, the support frame 4a is directly arranged above the beam 2a through a support rod, and the wire frame is located between the support frame 4a and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com