Flatbed knitting machine equipped with movable sinker

A sinker and flat knitting machine technology, applied in weft knitting, textiles, papermaking, knitting, etc., can solve problems such as large stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

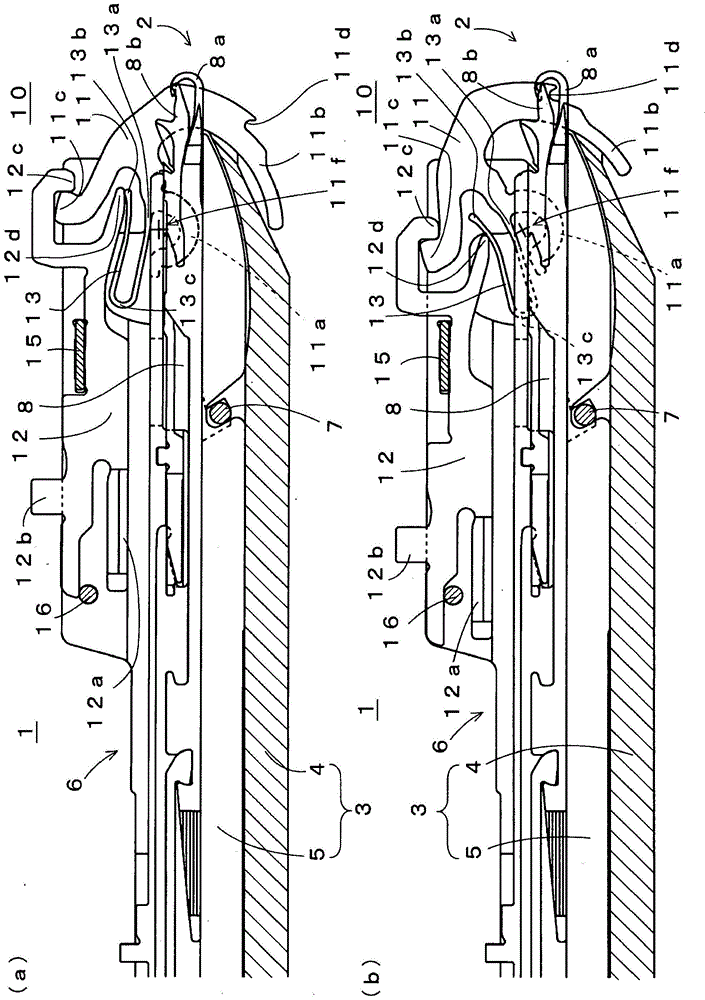

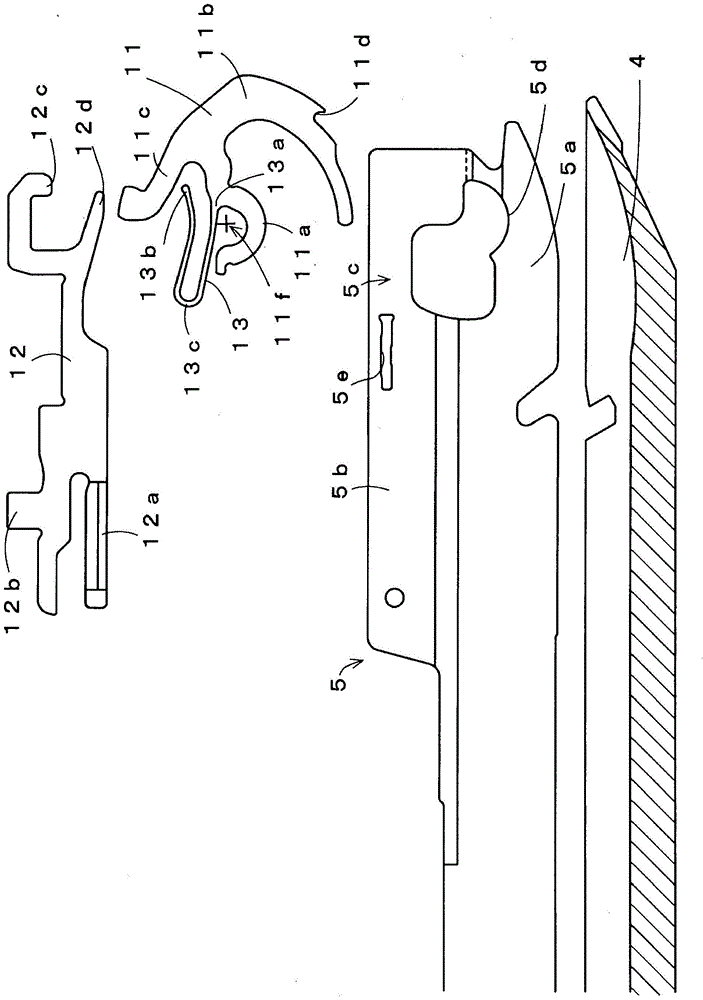

[0050] figure 1 A schematic structure and operation of a flat knitting machine 1 provided with a movable sinker 10 as Embodiment 1 are shown, figure 1 (a) represents the closed state, figure 1 (b) represents the open state. The flatbed knitting machine 1 knits a knitted fabric on the needle bed 2 side, and needle plates 5 are arranged side by side on a base 4 to form a needle bed 3 . Needle grooves 6 are formed between needle plates 5 juxtaposed at a constant pitch in a direction perpendicular to the paper surface. The base 4 and the needle plate 5 are positioned by the metal wire 7 penetrating in the direction perpendicular to the paper surface. The knitting needles 8 are accommodated in each needle groove 6 . The knitting needle 8 shown in the figure is a compound needle that opens and closes the hook provided at the front end of the needle body 8a on the tooth mouth 2 side by a tongue portion (tang) arranged at the front end of the needle mouth 2 side of the slider 8b, ...

Embodiment 2

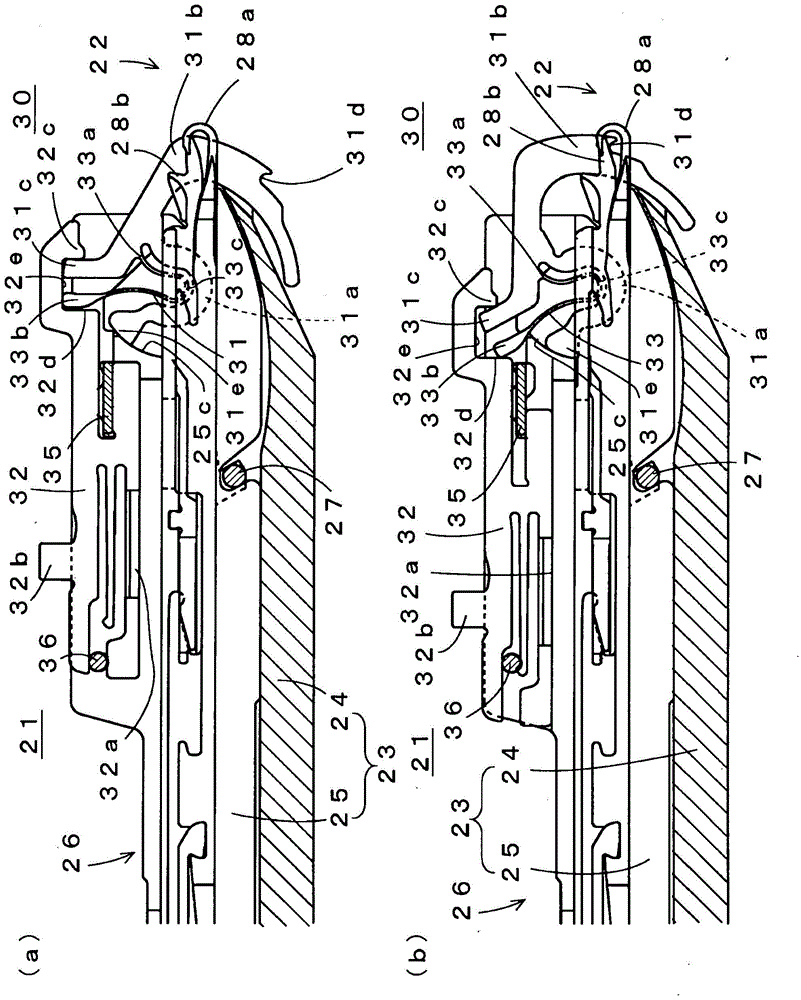

[0063] image 3 In Example 2, image 3 (a) The schematic structure and operation of the flat knitting machine 21 provided with the movable sinker 30 are shown in a closed state, image 3 (b) The schematic structure and operation|movement of the flatbed knitting machine 21 provided with the movable sinker 30 are shown in an open state. In this embodiment, although the bent portion 33c of the torsion spring 33 is accommodated inside the support portion 31a of the sinker 31, the other end 33b side of the torsion spring 33 is pushed by the passive arm 31c of the sinker 31 and the sinker. The action position of the front end portion 32c of the piece 32 is capable of pressing in the closed state from the pressing portion 32d on the side in the direction away from the tooth gap 22 . That is, near the front end of the sinker jack 32, one recess 32e opening downward is formed following the front end portion 32c. The recess 32e is formed such that the distance between the front end p...

Embodiment 3

[0068] Figure 5 In, as Example 3, Figure 5 (a) The schematic structure and operation of the flat knitting machine 41 provided with the movable sinker 50 are shown in a closed state, Figure 5 (b) The schematic structure and operation|movement of the flat knitting machine 41 provided with the movable sinker 50 are shown in an open state. In this embodiment, the swing of the sinker 51 is also supported by an upper support portion 51g and a lower support portion 51a corresponding to the support portion 11a of the first embodiment. Since the upper support portion 51g is provided, no space can be provided inside the lower support portion 51a, and the one end 53a side of the torsion spring 53 branches from the lower support portion 51a at a position in a direction away from the tooth gap 42 than the upper support portion 51g. The action arm 51b and the passive arm 51c are branched from the position in the direction close to the tooth gap 42 in the lower support portion 51a.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com