Disperse black dye composition, dye product containing composition, use and colored product

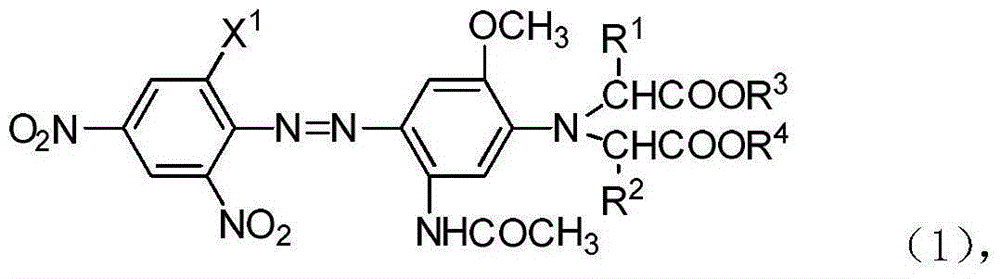

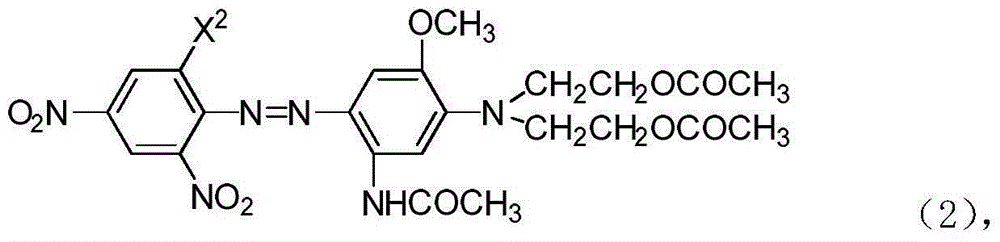

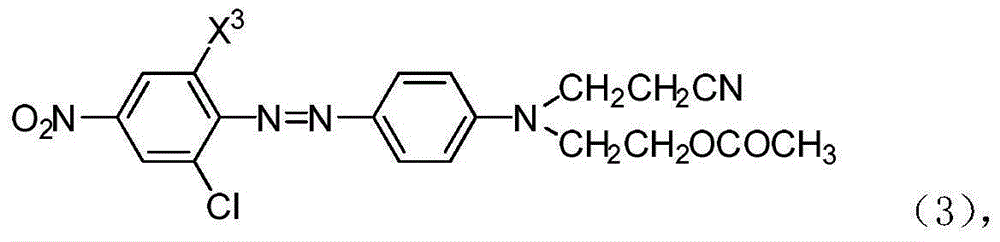

A dye composition, a technology of dispersing black, applied in dyeing method, organic dyes, textiles and papermaking, etc., can solve the problems of inability to repair color, affect product quality, fabric color and so on, and achieve the effect of perspiration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Combine 29 grams of component A represented by formula (1-1), 6.0 grams of component B represented by formula (2-1), 14 grams of component C represented by formula (3-1), 1.0 grams of formula ( Component D shown in 4-1) is mixed, pulverized with a pulverizer, and mixed to obtain the disperse black dye composition of the present invention. Based on the components of the dye compound used, the mass fraction of component A represented by formula (1-1) is 58%, and the mass fraction of component B represented by formula (2-1) is 12%, as shown in formula (3-1) The mass fraction of component C is 28% and the mass fraction of component D shown in formula (4-1) is 2.0%.

[0054] 50 grams of the disperse black dye composition, 60 grams of dispersant MF and 200 grams of water are used for micronization (for dispersion treatment) with a sand mill, and then spray-dried to obtain a solid product of the disperse black dye composition.

[0055] The double-layer filter paper filtration meth...

Embodiment 2~5

[0058] According to the dosage shown in Table 1, Component A, Component B, Component C, Component D, additives, synergists and 200 grams of water were used to grind and disperse with a sand mill, and then spray dried to prepare A solid dye product that is a mixture of disperse black dyes.

[0059] Table 1

[0060]

Embodiment 6~9

[0062] According to the dosage shown in Table 2, grind and disperse component A, component B, component C, component D, additives, water or synergist together with a sand mill. When the particle size is less than 2 microns Use a filter to filter out the dye slurry to obtain a liquid dye product of a disperse black dye mixture.

[0063] Table 2

[0064]

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com