Winding core transformer unloading turning frame

A technology for transformers and coiled iron cores, which is applied in the field of coiled iron core transformer unloading and turning frame, which can solve the problems of heavy core weight, inability to meet the unloading work of large coiled iron core transformer cores, and difficulty in the center of gravity of the iron core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

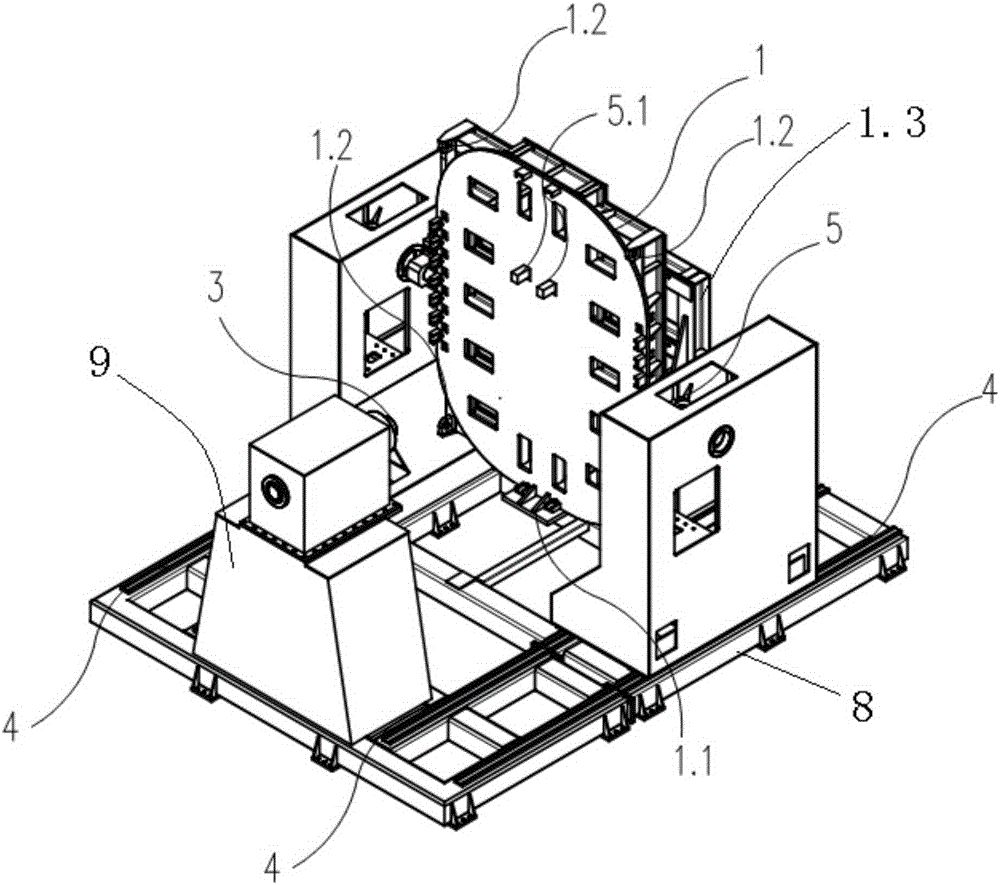

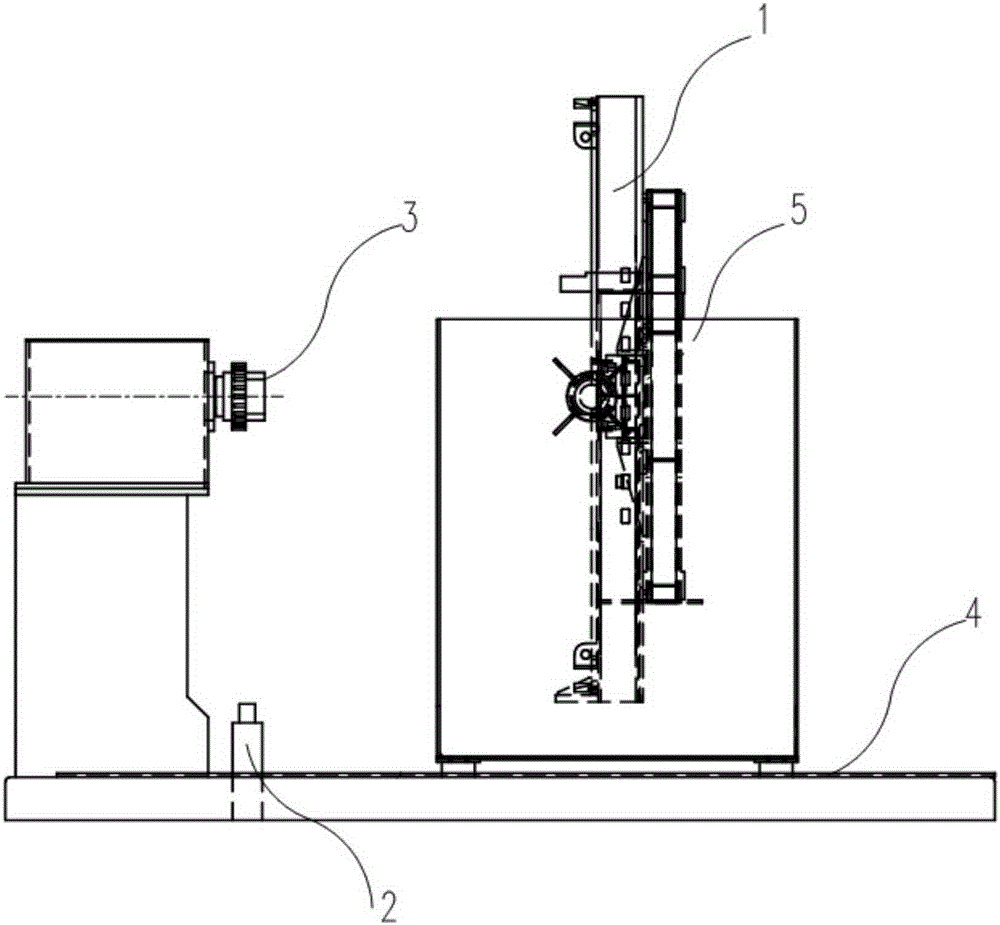

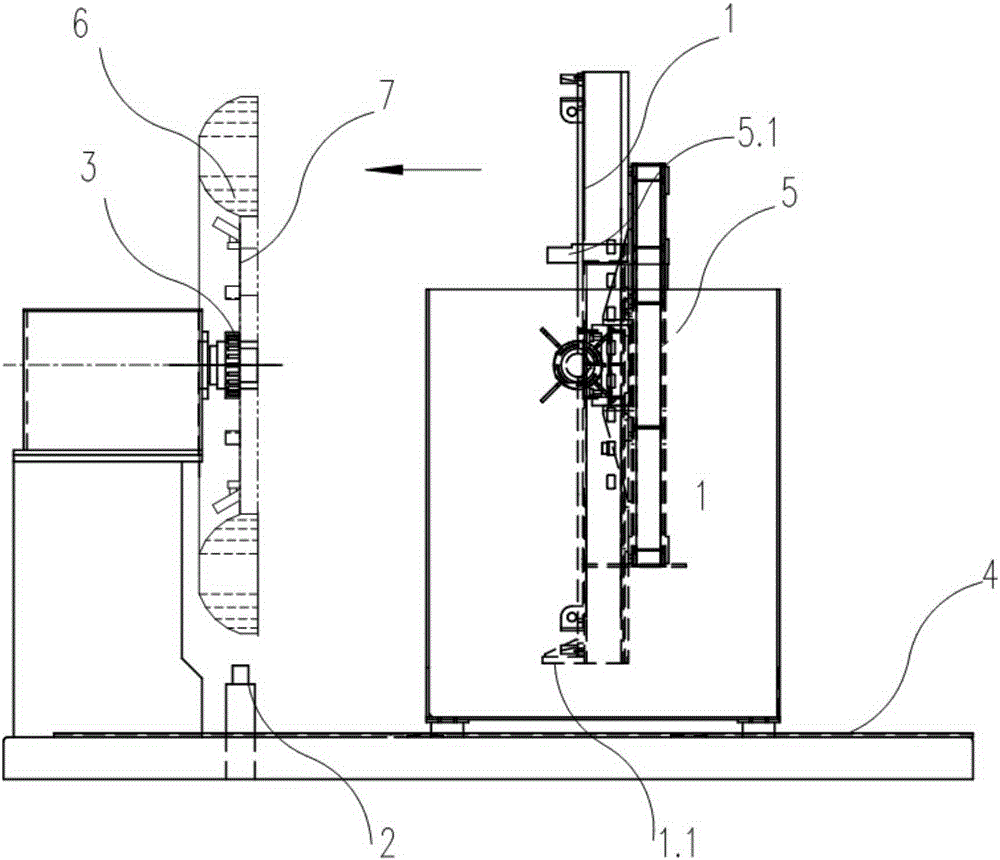

[0018] Such as figure 1 , 2 As shown, a rolling iron core transformer unloading turning frame, which includes iron core support and hoisting jig 1, jacking device 2, iron core core mold expansion mechanism 3, frame 8, turning frame 1.3, unloading turning Support platform 5, rocker turning mechanism and driving device, iron core core mold expansion mechanism 3 is installed on the iron core winding machine 9, and is coaxial with its transmission shaft, turning frame 1.3 is rotatably supported on the unloading turning support platform 5, the rocker arm turning mechanism is arranged between the turning frame 1.3 and the unloading turning support platform 5 so that it drives the turning frame 1.3 to rotate relative to the unloading turning support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com