A centering conveying mechanism and a centering conveyor having the same

A technology of conveying mechanism and centering mechanism, which is applied in the direction of conveyor objects, transportation and packaging, etc., which can solve the problems of goods deviating from the center of the conveyor, occupying space, and high cost, and achieve the effects of convenient transmission and exchange, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

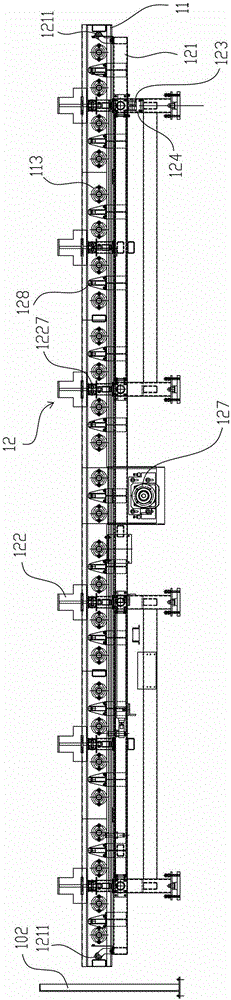

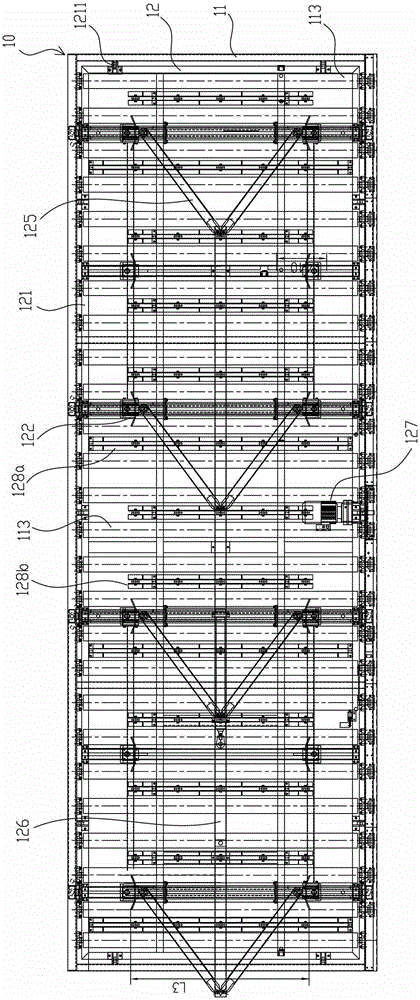

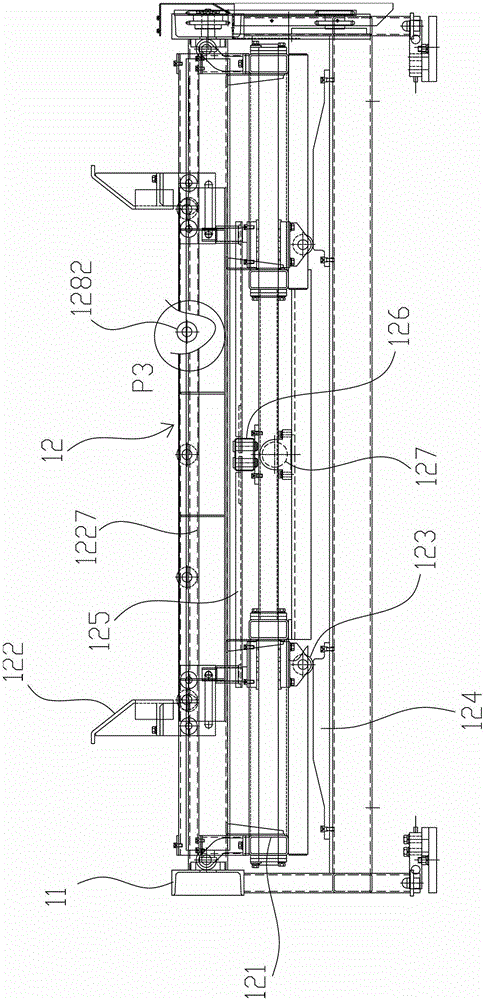

[0031] Such as Figure 1A ~ Figure 1C As shown, in a preferred embodiment of the present invention, the centering conveyor 10 of the present invention may include a conveying frame 11 and a centering conveying mechanism 12 to solve the problems of jacking and centering during the transportation of goods in and out of the warehouse . At one end of the centering conveyor 10, a door detection device 102 may be provided for detecting the entrance and exit of the warehouse.

[0032] combined reference Figure 2A ~ Figure 2C , in this embodiment, the conveying frame 11 includes a top frame part 111 and a bottom frame part 112, and the top frame part 111 is located on top of the bottom frame part 112 and is supported by it. The top frame part 111 may be a rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com