Wire cutter chain transmission tensioning assistance device

A technology of chain drive and auxiliary device, applied in the direction of conveyor, transportation and packaging, can solve the problems of shutdown, difficult to adjust the locking of the support plate 13, and the tensioning device can not be effectively tensioned, so as to achieve easy installation, Simple structure, no maintenance required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

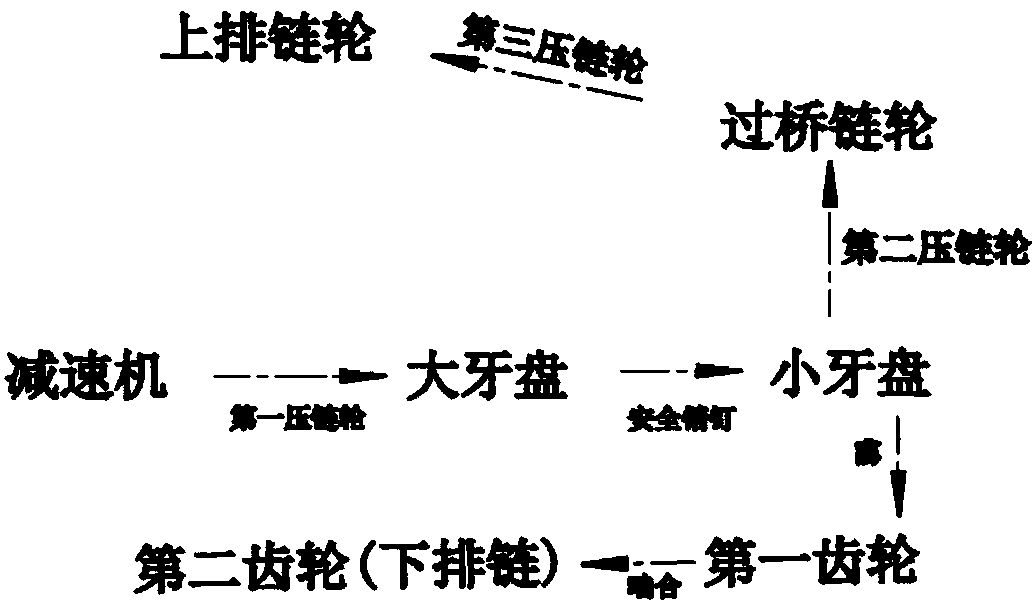

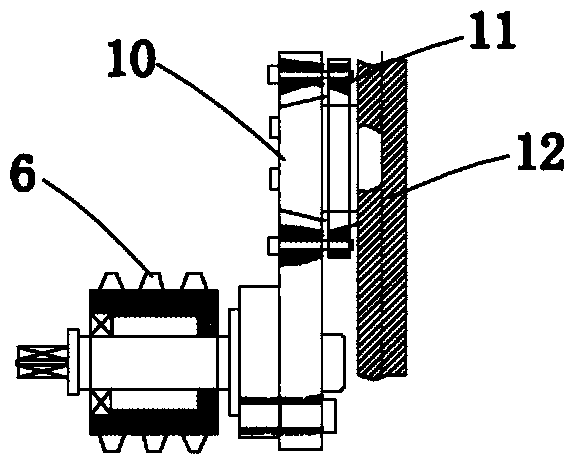

[0019] Embodiment: In conjunction with the accompanying drawings, the chain drive tensioning auxiliary device of the shredding machine of this embodiment, wherein, the chain transmission mechanism of the shredding machine includes: the sprocket on the output shaft of the reducer 1 is connected with the big crankset 2 through a chain, and the big crankset 2. It is coaxially connected with the small tooth plate 3 through the safety pin 9. The first gear is installed on the small tooth plate 3 through a key. The first gear meshes with the second gear to transmit the power to the lower chain; It is connected with the bridge crankset 4, and the bridge crankset 4 is connected with the upper sprocket 5 through the chain, and the power is transmitted to the upper chain, and the first pressure sprocket 6 is arranged on the chain between the reducer and the large crankset , the chain between the small chainring 3 and the bridge chainring 4 is provided with a second pressure sprocket 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com