Automobile storage battery holder assembly

A battery bracket and assembly technology, applied in the direction of vehicle components, electric power devices, power devices, etc., can solve the problems of affecting the safety distance of surrounding parts, small bolt installation and operation space, weak bracket assembly strength, etc., to achieve good modal , high installation efficiency and small cabin space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

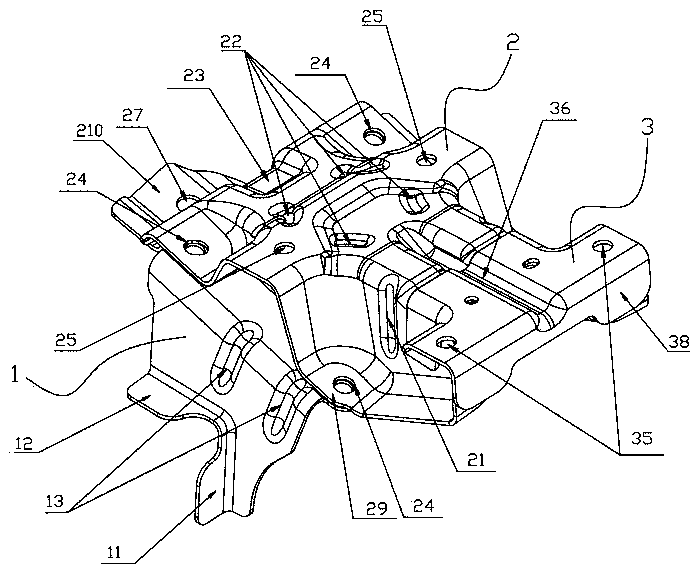

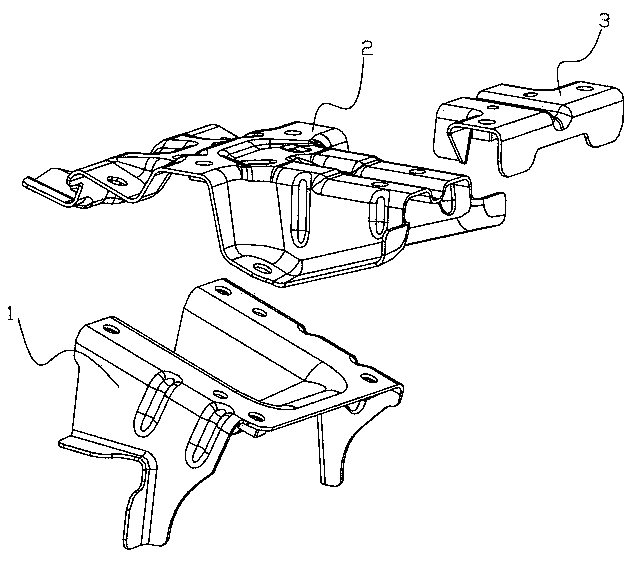

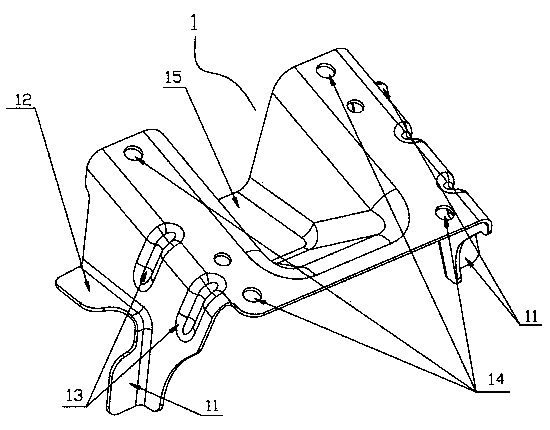

[0024] Such as Figure 1 to Figure 10 The shown car battery bracket assembly includes a lower bracket 1 , an upper bracket 2 and an upper bracket reinforcement 3 welded on the upper bracket 2 . The cross-section of the lower bracket 1 is M-shaped, and the lower edges on both sides are provided with a first lap flange 11 welded to the side of the longitudinal beam and a second lap flange 12 welded to the top surface of the longitudinal beam. The lower concave surface 15 welded on the top surface of the longitudinal beam is an inclined surface at an angle of 20° (or 30°, 40° or 45°) with the lower concave surface, and two brackets are provided on the front of the inclined surface Lower mounting holes 14, the rear of the inclined surface is also provided with two mounting holes 14 under the bracket, and the two sides of the lower bracket 1 are provided with lower brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com