Plate end soft fixed monolithic composite material leaf spring suspension structure

A composite material board, single-piece technology, applied in suspension, elastic suspension, interconnection system, etc., can solve the problems of small space for shape and performance change, short service life, many accessories, etc., to improve ride comfort and stability, ensuring driving smoothness and stability, and improving the effect of driving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

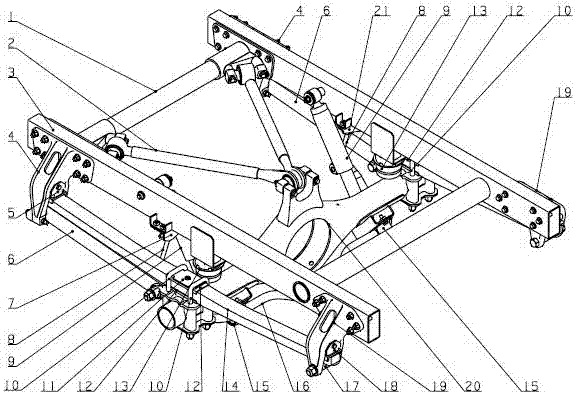

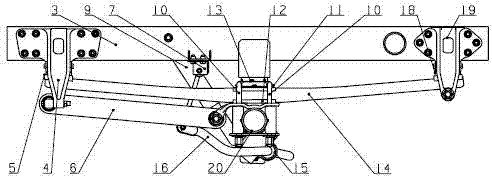

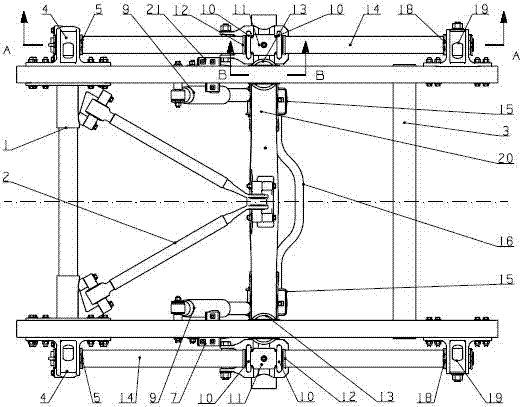

[0048] The plate end softly fixed monolithic composite leaf spring suspension mechanism includes a front beam 1, a V-shaped thrust rod 2, a vehicle frame 3, a front bracket 4, a front plate end soft slider 5, and a longitudinal variable section thrust rod 6 , left stabilizer bar connecting rod bracket 7, stabilizer bar connecting rod 8, shock absorber 9, U-shaped bolt 10, type bolt backing plate 11, leaf spring guard plate 12, variable characteristic buffer block 13, composite material leaf spring 14, stabilizer Rod support 15, stabilizer bar 16, rear drum 17, soft slide block 18 at rear plate end, rear support 19, rear axle 20, right stabilizer bar connecting rod support 21 etc.

[0049] First, the soft slider 5 at the front plate end and the soft slider 18 at the rear plate end are pre-installed on the front bracket 4 and the rear bracket 19 respectively with bolts, as figure 1 , Figure 7 , Figure 9 , Figure 11 shown.

[0050] Eight bolts are used to fix the two front b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com