Machine tool loading and unloading silo

A machine tool and silo technology, applied in the field of machine tool loading and unloading silos, can solve the problems of reducing the feeding capacity of the feeding device, reducing production efficiency, increasing the number of workpiece pallets, etc., achieving high reliability and improving the effect of feeding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

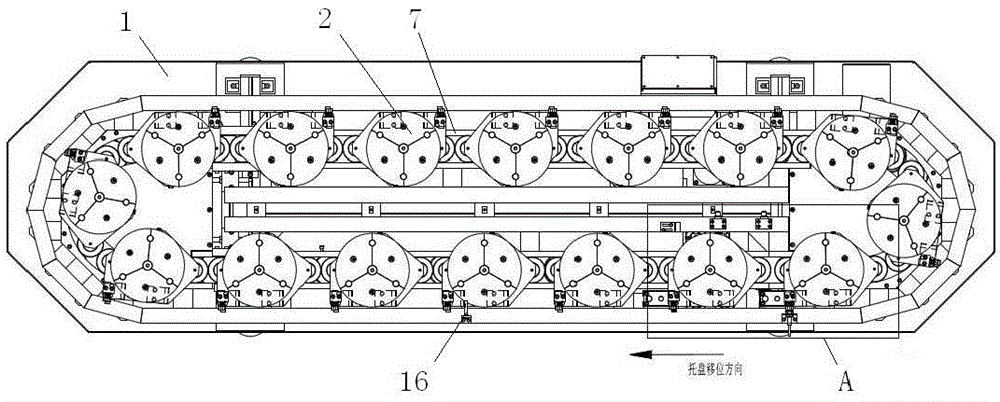

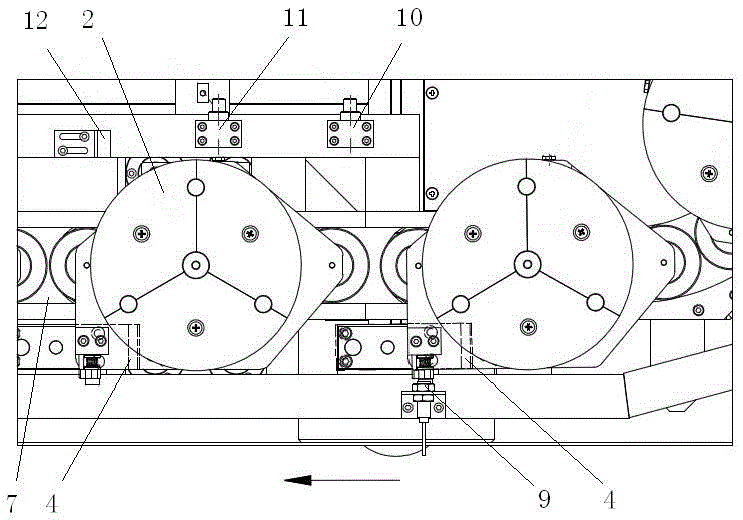

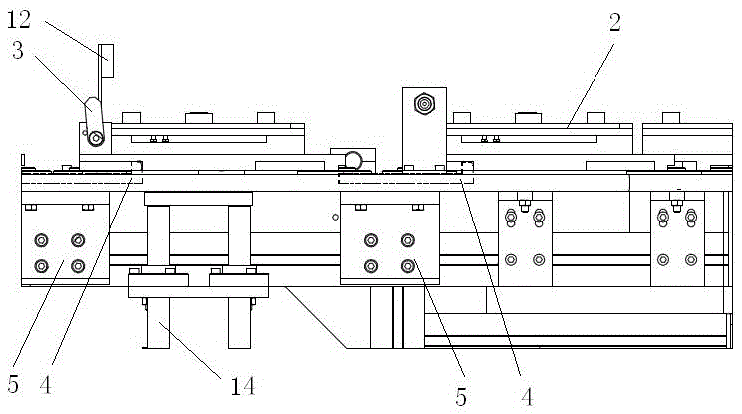

[0035] like figure 1 As shown, it is a structural schematic diagram of an embodiment of the loading and unloading bin of the machine tool of the present invention. The loading and unloading hopper of the machine tool in this embodiment includes a frame 1, on which a conveying device is arranged, and on the conveying device, a workpiece pallet 2 which is frictionally matched with it and is used for clamping workpieces is arranged at intervals, and the workpiece pallet 2 is provided with a For the state pointer 3 indicating whether there is a clamped workpiece and has two position states, two baffle mechanisms for limiting the position of the workpiece tray 2 are provided on the frame 1. The plate 4 and the baffle cylinder 5 used to drive the movement of the baffle 4, the conveying device area between the two baffles 4 is the workpiece grabb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com