Micro-power mining machine capable of obtaining both high-quality river sand and multiple metal mineral powder

A technology for mining machines and metal mines, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of high water content in ore sand, inability to extract, rapid water flow, etc., and achieve simple machine structure, easy operation, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

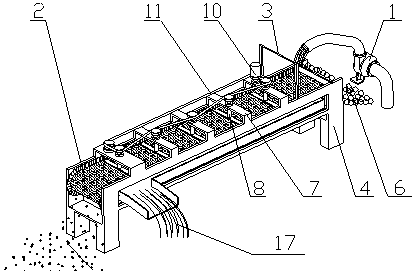

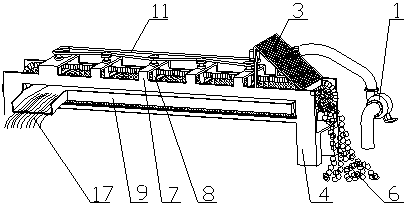

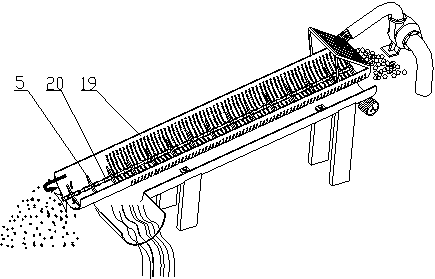

[0017] Such as figure 1 , figure 2 As shown, on the double-layer frame body 4, a conveyor belt 2 driven by a motor is set (the motor driving the conveyor belt is omitted in the figure), and a stirring block installation mechanism is also provided on the frame body, that is, in a plurality of agitator frames On 7, stirring block 8 is installed respectively, and stirring block 8 is suspended on the conveyer belt and just contacts lightly with conveyer belt or slightly has spacing. Its working method is: the sand suction pump 1 sprays the stones, river sand, water, etc. sucked from the river bed to the filter screen 3, and filters out impurities such as larger pebbles 6, and the water column falls into the conveyor belt covered with drainage holes. After it is installed, the diameter of the drain hole is between 0.20-0.30mm. In order to allow the river sand to be stirred during the transmission process so that more fine sand is leaked, a plurality of stirring blocks 8 are stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com