Electrical control system and method for food waste processor

A food waste treatment and electrical control system technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of reducing the service life of food waste processors, hidden safety hazards, etc., and achieve convenient operation range and water saving Quantity, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

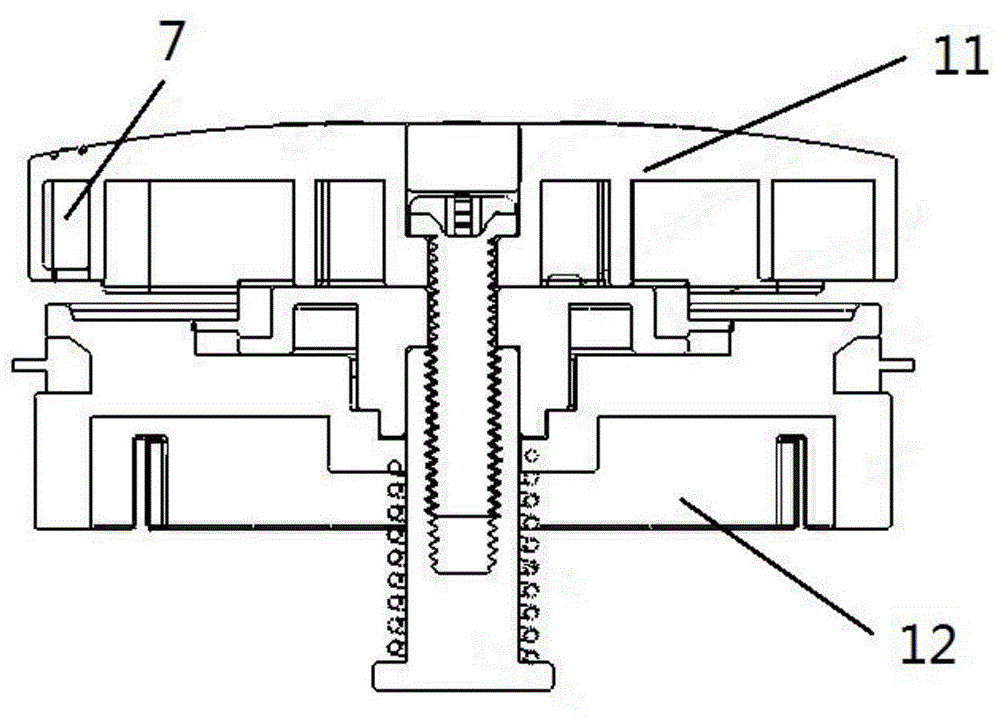

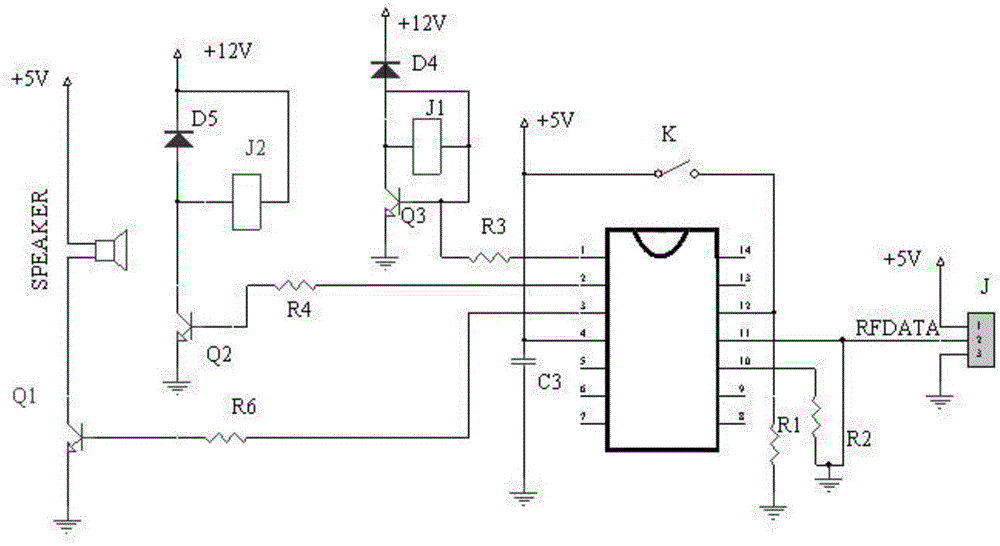

[0035] Such as figure 1 , figure 2 In the described embodiment, an electrical control system of a food waste disposer includes a water plug switch 1, a water plug connecting seat 2, a cavity 3 and a DC motor assembly, and the water plug switch 1 is installed through the water plug connecting seat 2 At the upper end of the cavity 3, the DC motor assembly is installed at the lower end of the cavity 3, and the water plug switch 1 is provided with a magnet 7, which is a square magnetic steel, wherein the water plug switch 1 includes a water plug cover 11 and a water plug The lower cover 12, the water plug upper cover 11 is flexibly connected with the water plug lower cover 12, the magnet 7 is installed on the inner side of the outer circumference of the water plug upper cover 11, the water plug lower cover 12 is fixedly installed on the water plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com