A method of dynamic balancing of aircraft propeller by the method of center of mass dynamic correction

A dynamic correction and propeller technology, applied in the field of aircraft maintenance, can solve problems such as uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

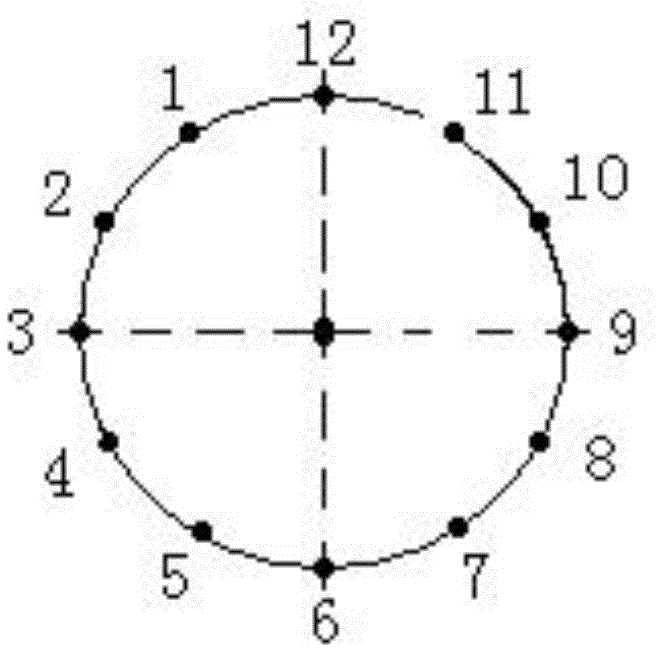

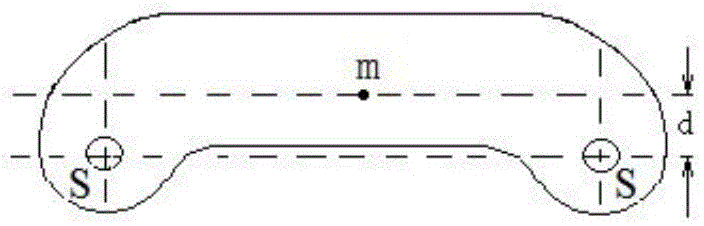

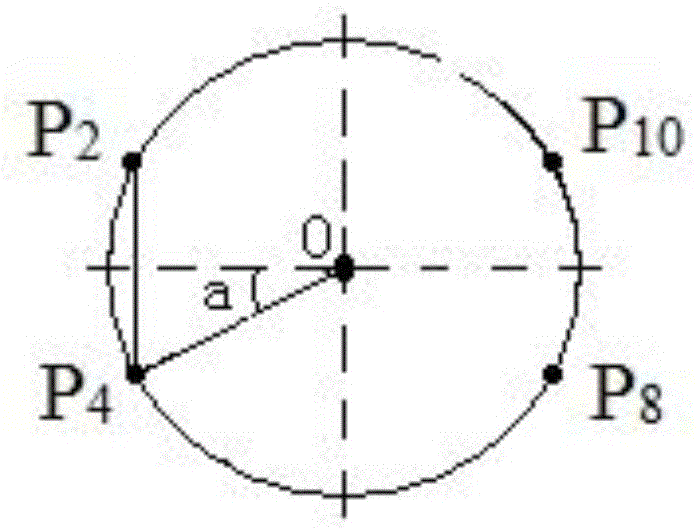

Image

Examples

Embodiment 1

[0118] Embodiment 1. The dynamic balance trimming effect contrast on TB200 aircraft:

[0119] 1) with the traditional method

[0120] The traditional method is that the propeller vibration value tester directly outputs the calculation result as a solution based on the measured vibration value level and light point position data. The calculation process is solidified inside the tester as a part of the system software and is not disclosed to users as a technical secret , so when using the traditional method, you only need to select the function menu according to the prompts on the tester interface, and there is no problem of selecting the trim coefficient and dynamic correction of the center of mass, and the solution of the traditional method is to install a counterweight at one position.

[0121] The dynamic balance trimming process of the traditional method is as follows:

[0122]

[0123] The vibration value is reduced from 0.46IPS to 0.18IPS when trimming to the 7th time...

Embodiment 2

[0132] Embodiment 2. Comparison of dynamic balance and trimming effects on LE500 aircraft:

[0133] 1) with the traditional method

[0134] The traditional method is that the propeller vibration value tester directly outputs the calculation result as a solution according to the measured vibration value level and light point position data. You only need to select the function menu according to the prompts on the tester interface. There is no selection of trim coefficients and The problem of dynamic correction of the center of mass, and the solution of the traditional method is "trail" in nature, which is characterized in that a counterweight is installed at one position each time, and each balance is carried out on the basis of the previous one, and the final installed balance The weight is the accumulation of the mass of each installed counterweight.

[0135]

[0136] A total of 7 consecutive trimmings using the traditional method achieved an effect of 0.16IPS, and finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com