sequential coding device

A sequential and weight technology, applied in the field of automatic weight adding device, can solve the problems of the system not being able to measure and automatically compensate in real time, difficult to keep the pressure stable, and the error of the verification result, etc., and achieve the effect of accurate adding, simple device and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

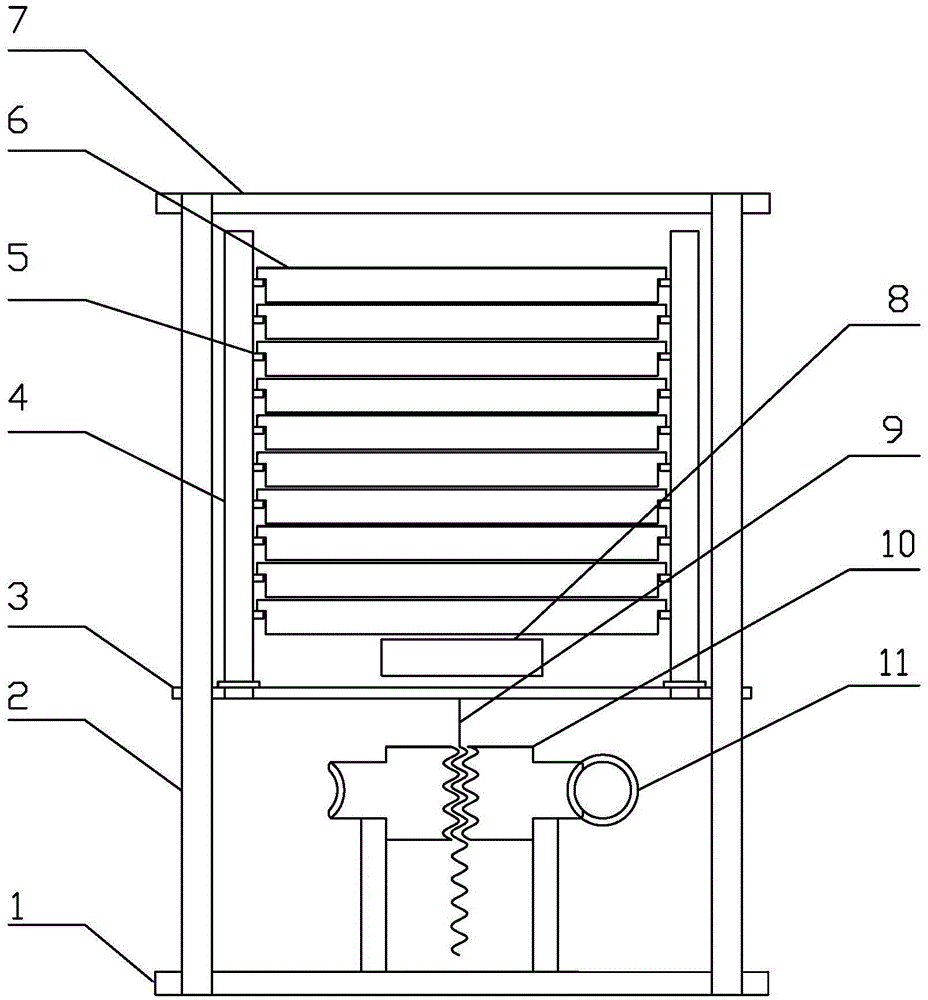

[0027] Such as figure 1 As shown, the sequential weighting device of the present invention mainly includes: a lower fixed plate 1, a support guide column 2 (the number is greater than or equal to 2), a supporting plate 3, a weight bracket guide column 4 (the number is greater than or equal to 2), weights Support block 5, weight 6 (weight can be different), upper fixed plate 7, weight pallet 8, connecting screw 9, worm wheel 10, worm screw 11.

[0028] Wherein, the lower fixed plate 1, the supporting guide column 2, the supporting plate 3, and the upper fixed plate 7 form the basic frame of the sequence adding device. The lower fixed plate 1 and the support guide column 2, and the support guide column 2 and the upper fixed plate 7 are fixedly connected; the supporting plate 3 can slide up and down along the support guide column 2; the worm wheel 10 and the worm screw 11 installed on the lower fixed plate 1 Constitutes the driving device of adding code sequentially with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com