A casing coding device and method

A sleeve and coder technology, applied in printing devices, copy/marking methods, typewriters, etc., can solve the problems of difficult production quality assurance, high labor intensity, shortened ship construction cycle, etc., to ensure quality and stability, avoid The effect of repeated coding and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: A casing coding device.

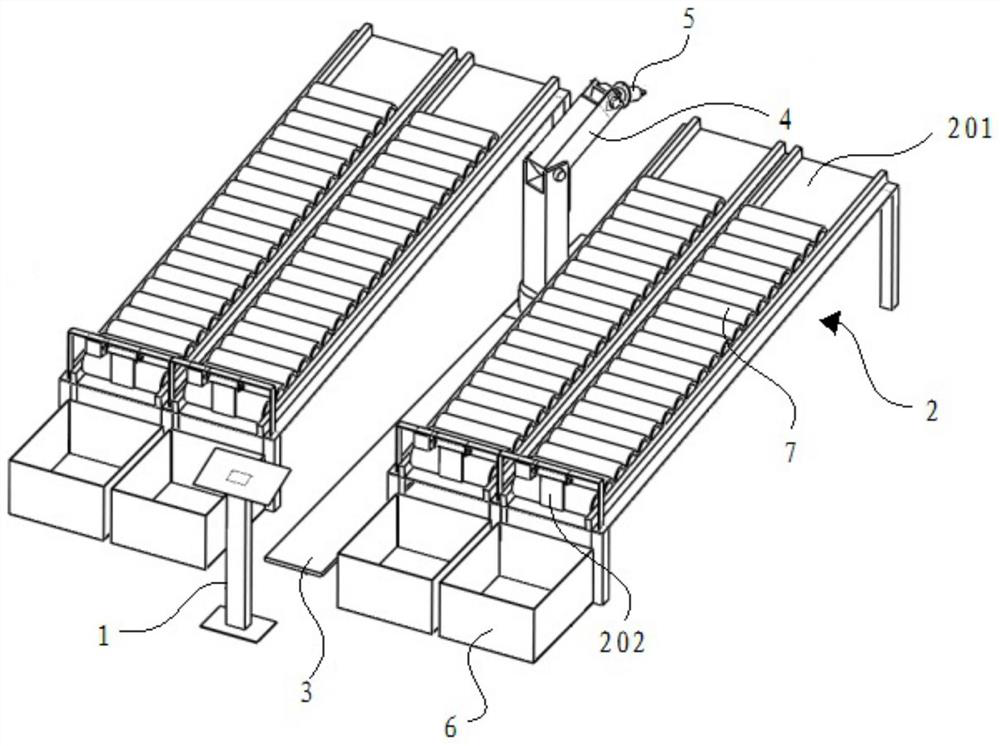

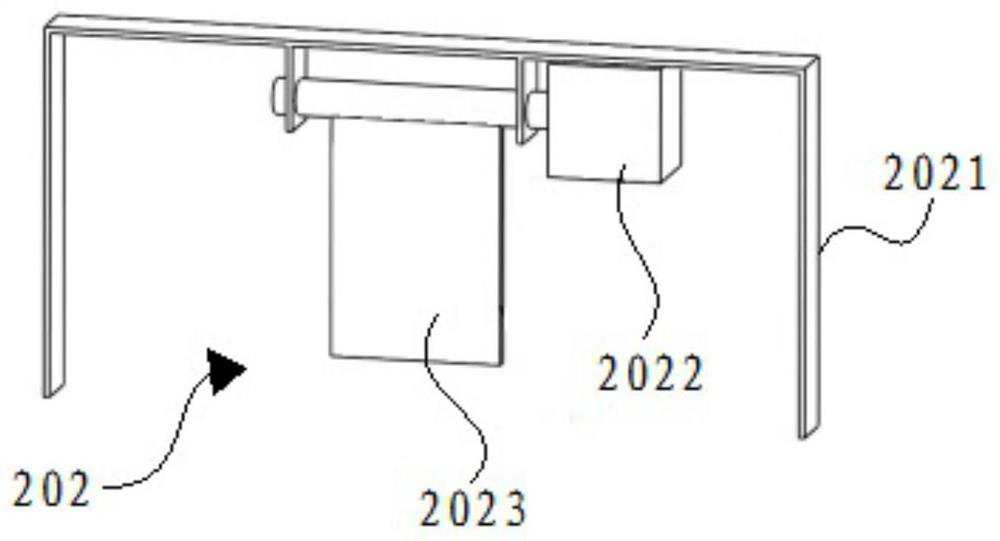

[0030] like figure 1 As shown, a casing coding device according to a preferred embodiment of the embodiment of the present invention includes: a controller 1, a plurality of storage racks 2, and slide rails 3; each of the storage racks 2 is arranged in parallel for storing casings 7. The storage rack 2 includes a slideway 201 and a baffle mechanism 202. The slideway 201 is in the shape of a slope, and the lower end of the slideway 201 is installed with a stopper for holding the sleeve 7 to prevent it from sliding down. A plate mechanism 202, the baffle mechanism 202 is electrically connected to the controller 1; the slide rail 3 is arranged in parallel with each of the storage racks 2, and a robot 4 is slidably installed on the slide rail 3, and the robot 4 is provided with a coder 5 , the robot 4 is electrically connected to the controller 1 , and the coder 5 is electrically connected to the controller 1 .

[0031] Based on the...

Embodiment 2

[0039] Embodiment 2: A casing coding method.

[0040] A casing coding method according to a preferred embodiment of the embodiment of the present invention is based on the casing coding device as described in any of the above, and the method steps include:

[0041] S1, the controller receives the coding information sent from the external PC, matches the casing of the corresponding specification according to the coding information, and detects whether the storage rack storing the casing of the corresponding specification has uncoded casing;

[0042] S2, when it is detected that there is an uncoded casing, the controller sends a control signal to the robot, and the robot slides to the front of the corresponding storage rack and feeds back the signal to the controller;

[0043] S3, the controller receives the feedback signal from the robot and sends the control signal to the coder, and the coder identifies the uncoded casing and codes it;

[0044] S4, after the coder completes c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com