Start-up burner igniter nitrogen protection device

A technology of nitrogen protection device and start-up burner, which is applied in the direction of combustion ignition, burner, ignition by electric spark, etc., which can solve the problems of ensuring the safety of the ignition rod head, the large impact of the ignition rod head, and the easy carbonization of sealing materials. , to prevent the danger of carbonization, easy to operate, and prevent radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the practical application structure of the present invention is not limited to the following embodiments.

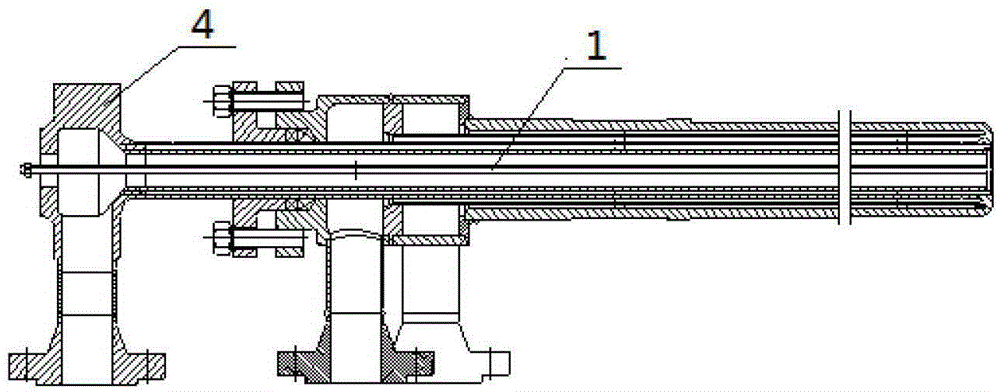

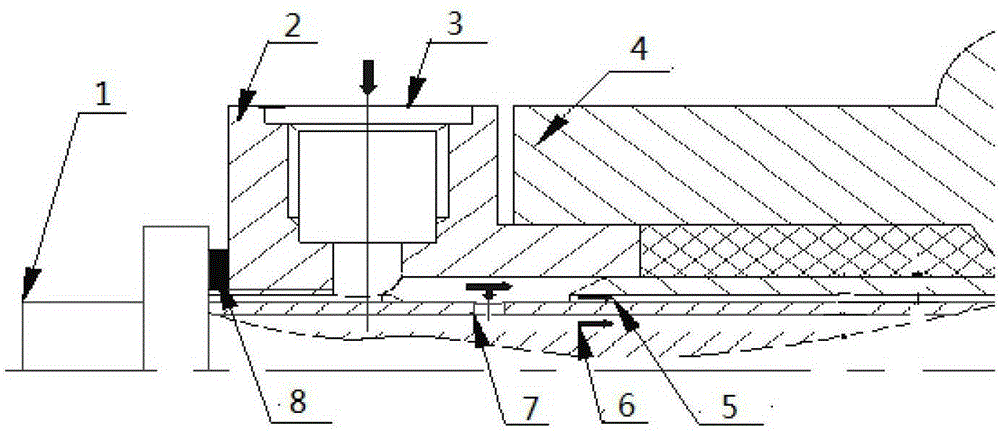

[0013] Referring to the accompanying drawings, the start-up burner igniter nitrogen protection device according to the present invention includes a sleeve 2 and an ignition rod 1 fitted on the start-up burner 4, the sleeve 2 is set on the rear part of the center channel of the start-up burner 4, and the ignition The rod 1 passes through the sleeve 2 and is pushed in from the tail of the start-up burner 4, and extends to the head of the burner through the central channel of the start-up burner 4. The side wall of the barrel 2 is provided with a nitrogen inlet 3 leading into the central channel of the start-up burner 4, and a nitrogen inlet 7 is provided on the rear wall of the ignition rod 1. In actual work, before the start-up burner runs, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com