A construction method of all-welded box truss composite segments

A construction method and all-welding technology, applied in construction, bridge construction, erection/assembly of bridges, etc., can solve the problems of not being able to meet the construction period of Hutong Railway, increasing the risk of the construction process, and the large span of the main span, etc. The effect of maintenance workload, shortened installation period and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

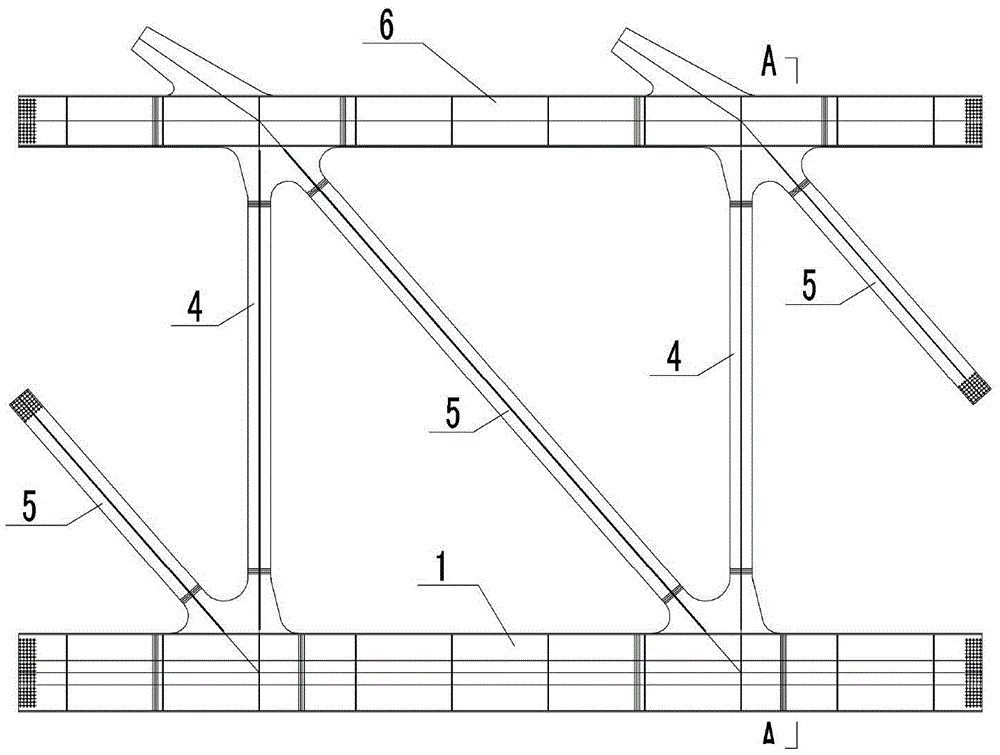

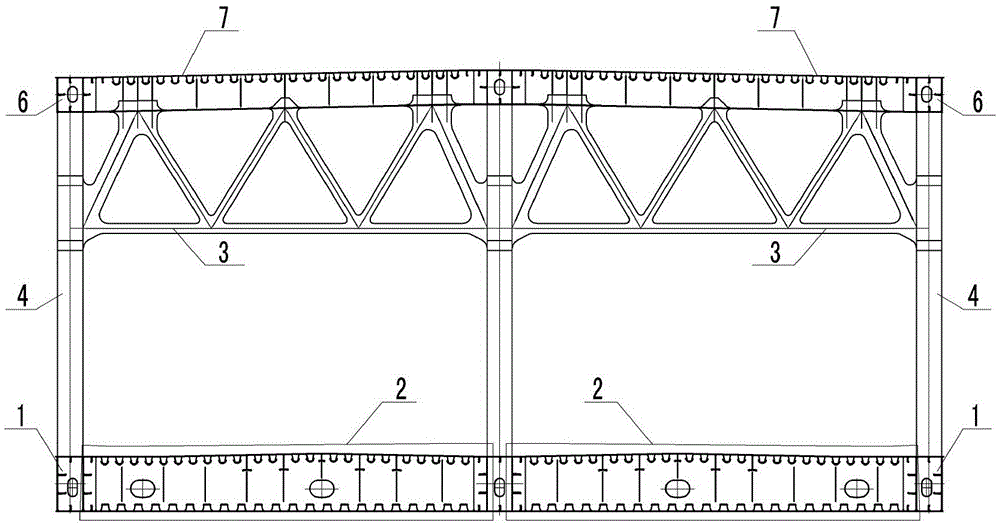

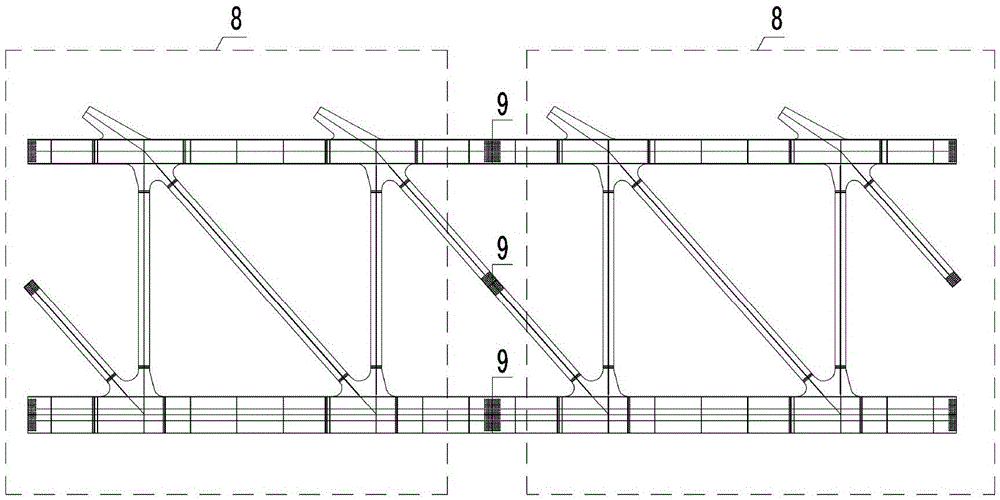

[0018] refer to figure 1 , figure 2 , the concrete construction steps of the present invention are as follows:

[0019] 1) According to the sequence of installation, the main girder is divided according to the length between two sections as a new type of box-truss composite section,

[0020] 2) Fabrication of new box truss composite segments:

[0021] ①Make plate unit: make the plate unit of each unit unit that composes the box truss composite segment, the plate unit includes the main truss lower chord, the main truss upper chord, the upper bridge deck, the lower bridge deck steel box, the main truss vertical bar, and the oblique bar And the horizontal connecting plate unit;

[0022] ② Welding of combined segment unit elements: welding the lower chord 1 of the main truss and the steel box 2 of the lower deck, welding the upper chord 6 of the main truss and the deck 7 of the upper deck, welding the transverse connecting system 3 and the vertical bar 4 of the main truss, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com