Wet joint construction for the connection between prefabricated bridge pier columns and cover beams

A technology of connecting parts and prefabricated assembly, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problem that the connection of prefabricated components cannot be directly realized, and achieve the effect of low construction difficulty, convenient construction and low construction precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

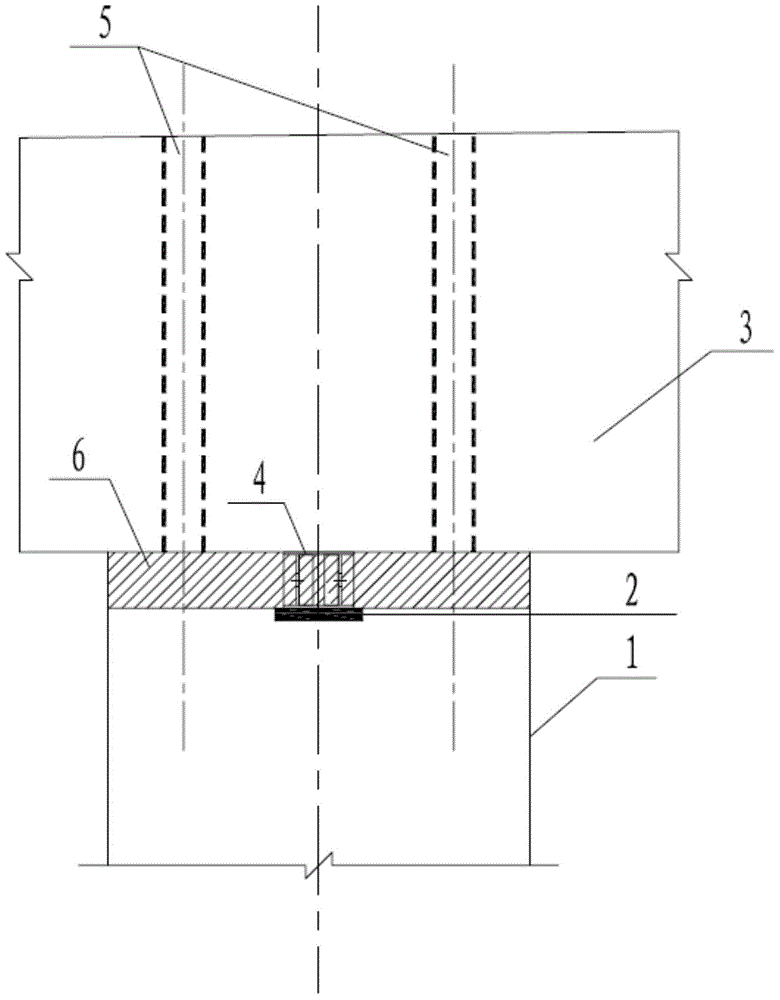

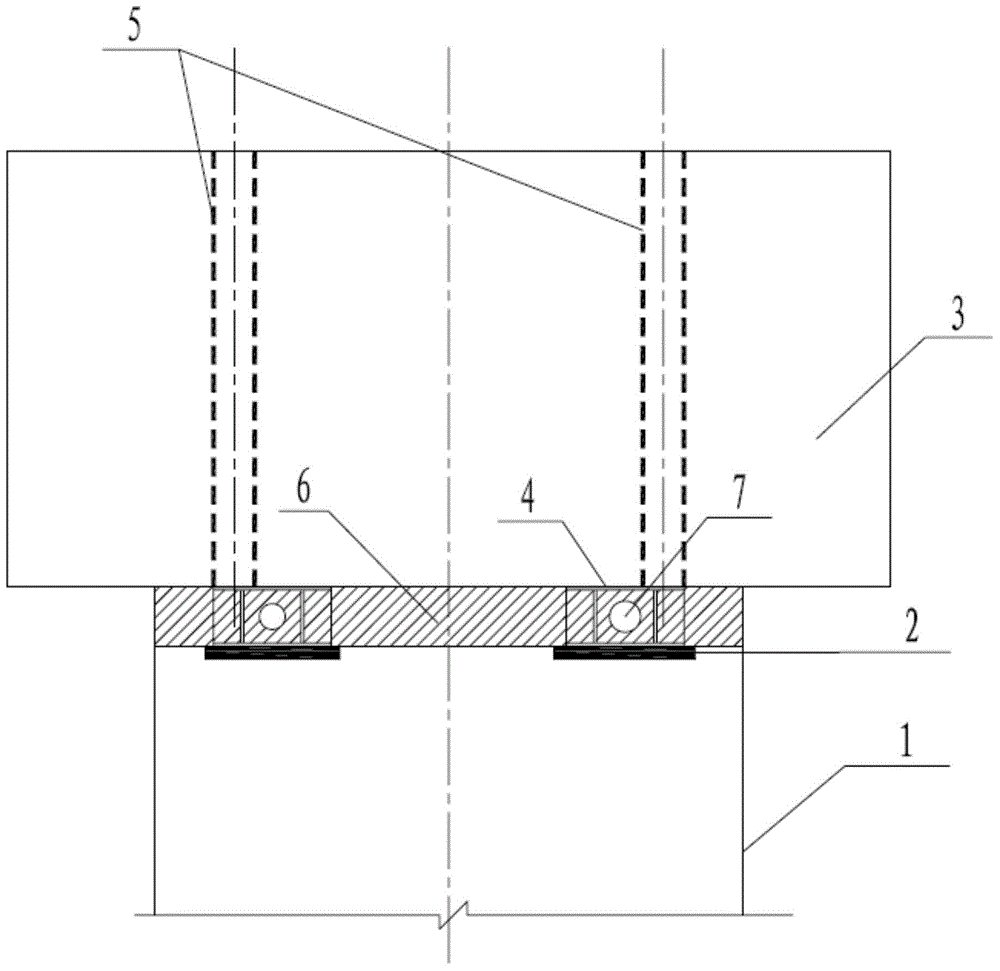

[0015] Such as Figure 1 to Figure 3 As shown, this embodiment proposes a wet joint structure for the connection between the prefabricated and assembled bridge pier column and the cap beam, which includes: a steel plate 2 pre-embedded on the top surface of the bridge pier column 1, and pads are arranged on the pier column 1 and the cap beam 3. The spacer 4 in between passes through the hole 5 provided on the cap beam 3 and the cast-in-place concrete layer 6. As shown in the figure, the cushion block 4 of this embodiment is fixed on the steel plate 2, the cast-in-place concrete layer 6 is filled in the connection part of the pier column 1 and the cap beam 3, and one port of the hole 5 is connected to the cast-in-place concrete layer 6, the steel plate 2 and the cushion block 4 are all wrapped in the cast-in-place concrete layer 6.

[0016] Specifically, the cushion block 4 of this embodiment is two box-shaped steel structure cushion blocks, and the web of the cushion block 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com