A rope-like textile processing system

A processing system and textile technology, applied in liquid/gas/vapor rope fabric processing, folding textile material storage, processing textile material containers, etc., can solve the problems of fabric knotting and entanglement, and achieve the effect of solving knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

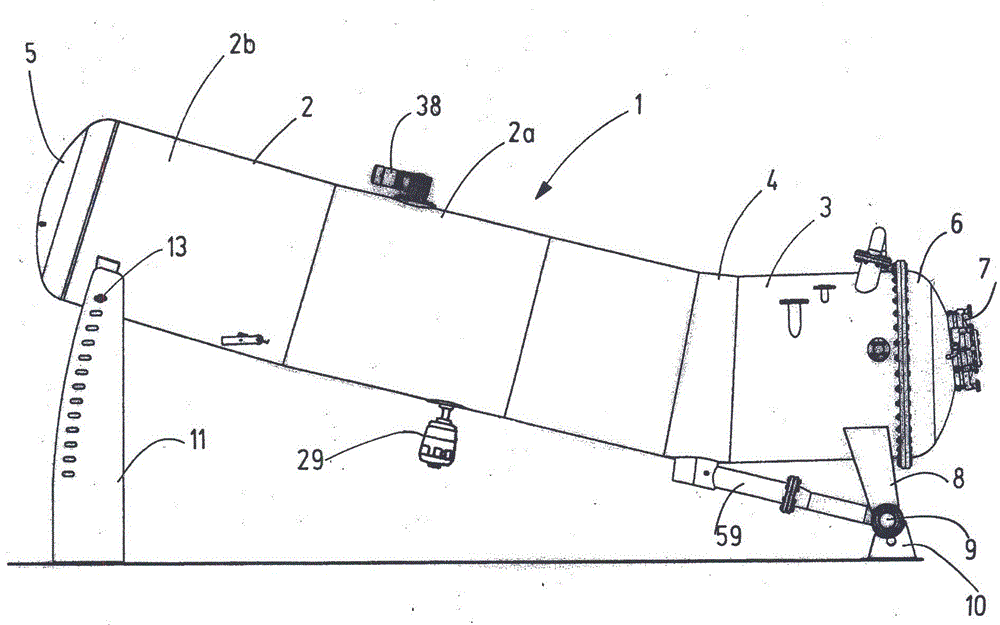

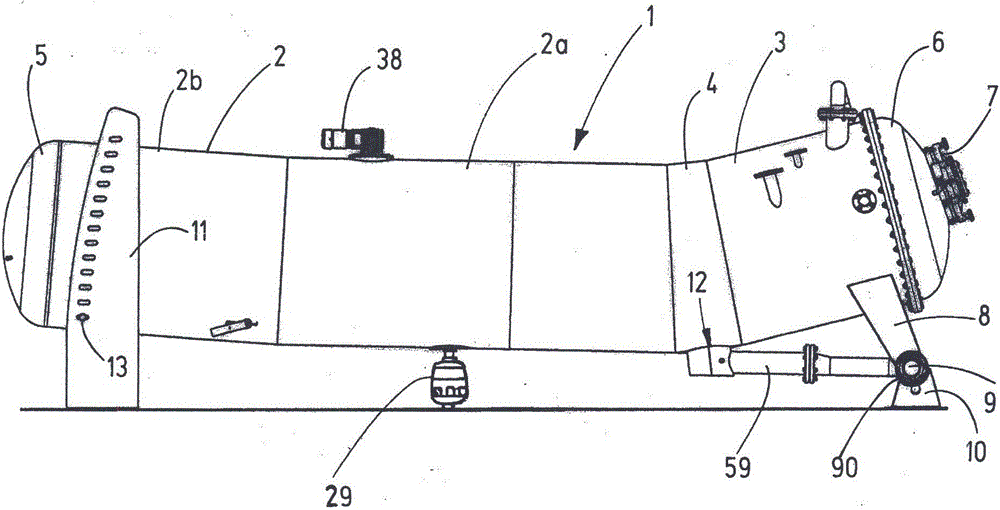

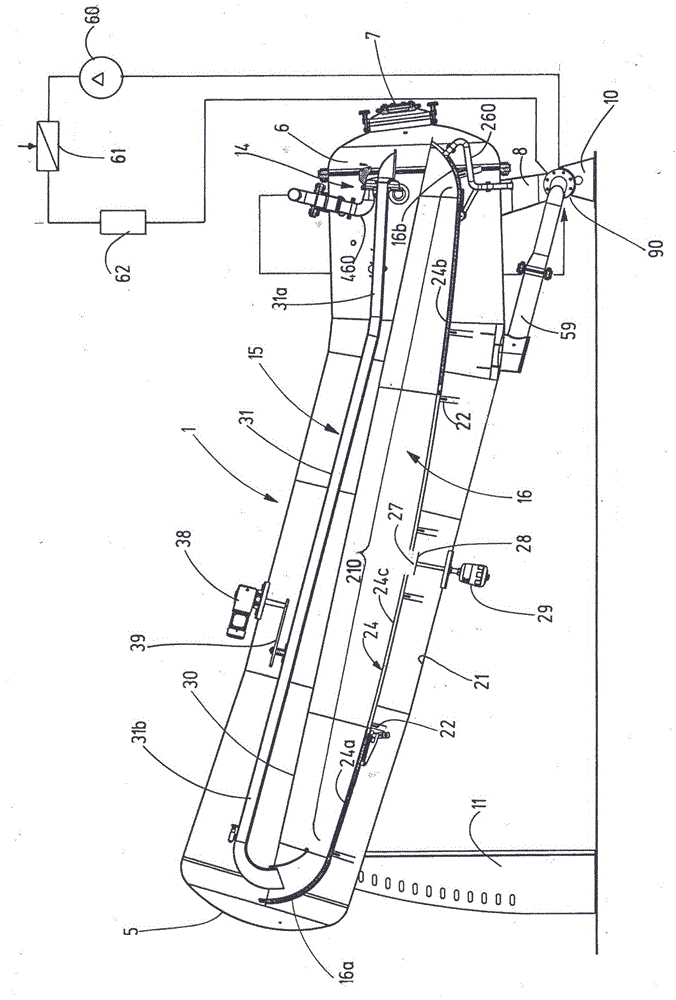

[0048] Please refer to the attached figure 1 to attach image 3 , the rope-like textile processing system in the present invention mainly processes rope-like textiles, and the textiles can move continuously in the system. In this embodiment, the cloth dyeing system is taken as an example. The basic part of the present invention is a tubular processing container 1. In this embodiment, the diameters of the front and back of the processing container 1 are the same, and it includes a longer first cylindrical tube portion 2 and a shorter second cylindrical tube portion. The pipe part 3, the first cylindrical pipe part 2 and the second cylindrical pipe part 3 are connected together through the intermediate pipe part 4, thereby forming a wedge-shaped st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com