Convenient energy-saving static OAR (Organics Aerobic oxidation Resources) treatment device

A treatment device and energy-saving technology, which is applied in the field of convenient and energy-saving static OAR treatment devices, can solve the problems of small space, unfavorable odor collection and treatment, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The following embodiment 1 is the embodiment of the single device of the device, and embodiment 2 is the embodiment of the application of the devices in series.

[0040] Example 1

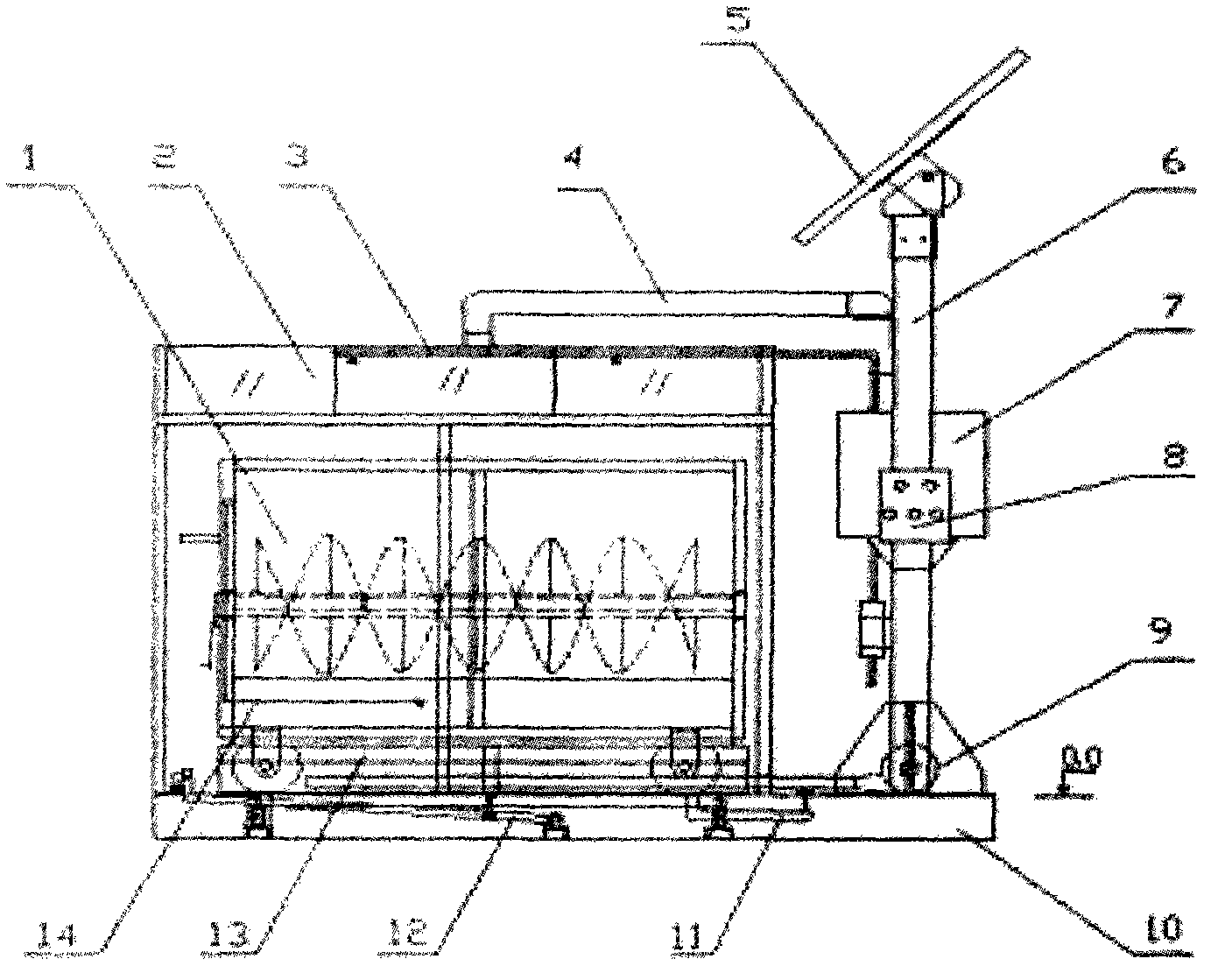

[0041] according to figure 1 Make this device in which:

[0042] The turnover fermentation vehicle 1 is made of anti-corrosion carbon steel plate and profiles, 2000mm×1700mm×1500mm, and the heat preservation warehouse 2 is made of sunlight board and light steel bracket;

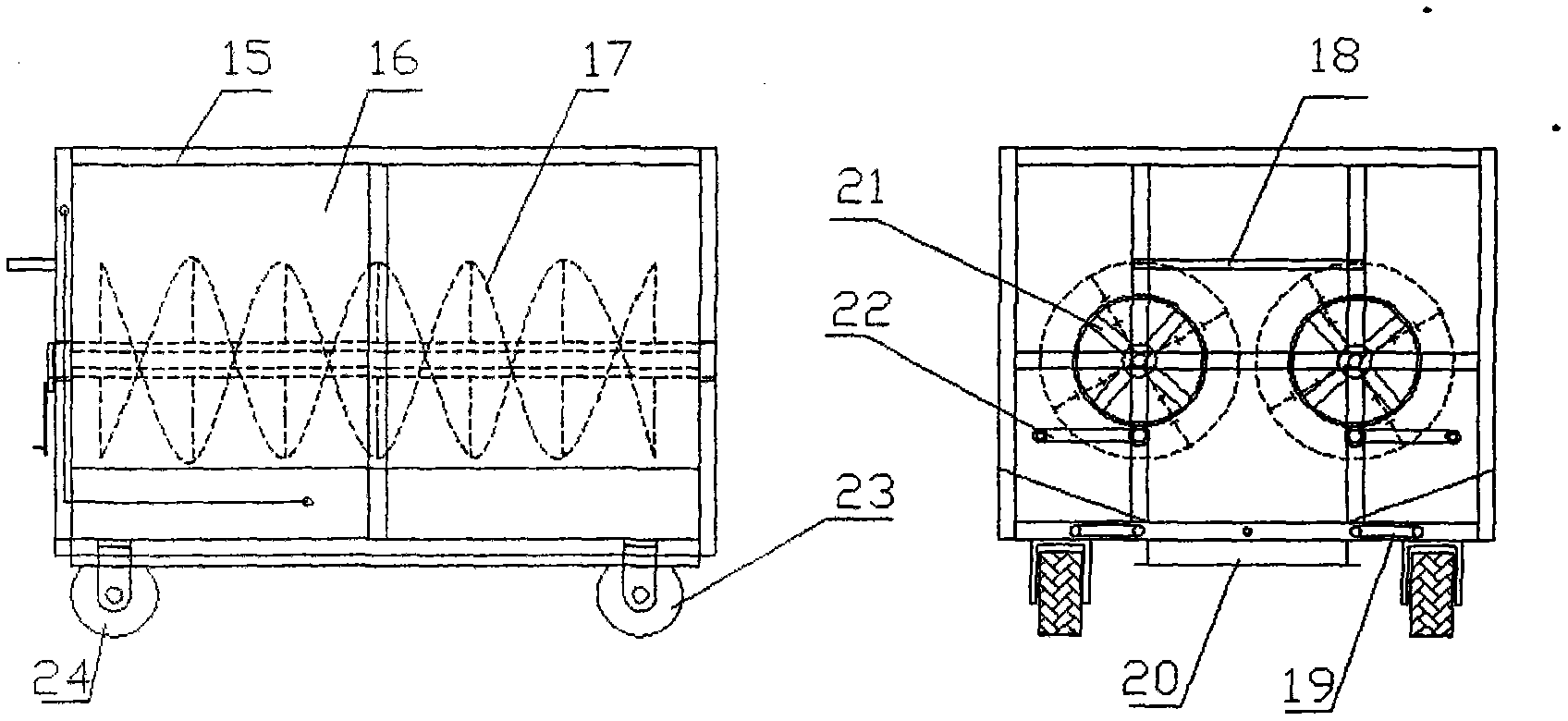

[0043] The turner 17 is made of anti-corrosion carbon steel, the diameter of the main shaft is 80mm, and the diameter of the spiral belt is 10mm; the rocker arm 22 and the main shaft are driven by gears, and the transmission ratio is 1:10;

[0044] The exhaust system 4 adopts DN100 UPVC pipe, the exhaust fan is a 120w axial flow fan, and the outlet is connected to the deodorizer; the spray system 3 adopts a DN15 galvanized pipe and a 100w booster pump; the filtrate pipe 11 adopts a DN40 hose.

[0045] The solar power gen...

Embodiment 2

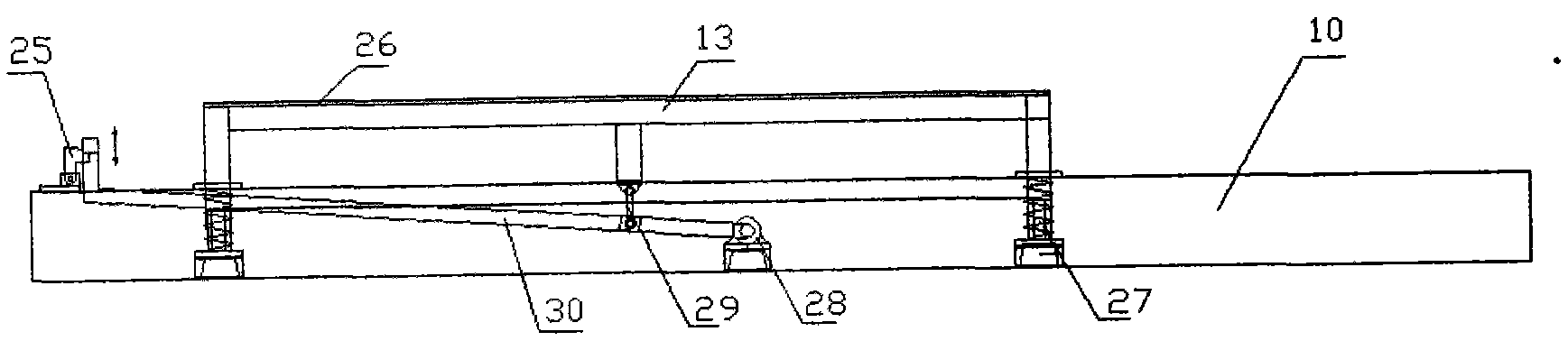

[0052] Such as Figure 4 As shown, six devices in Embodiment 1 are arranged in rows, wherein: exhaust pipe, spray pipe and filtrate pipe 11 are connected in parallel; the control system remains independent; the number of single solar panels 5 remains unchanged, and each control system combined into 1.

[0053] Each warehouse is independently operated and managed uniformly, and its operation sequence is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com