Vertical unpowered strip stocker

A power belt and material storage technology, applied in the field of vertical unpowered strip steel storage machine, can solve the problems of high manufacturing precision, difficult design, high production cost, etc., achieve low manufacturing precision requirements, reduce processing difficulty and Production cost, production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

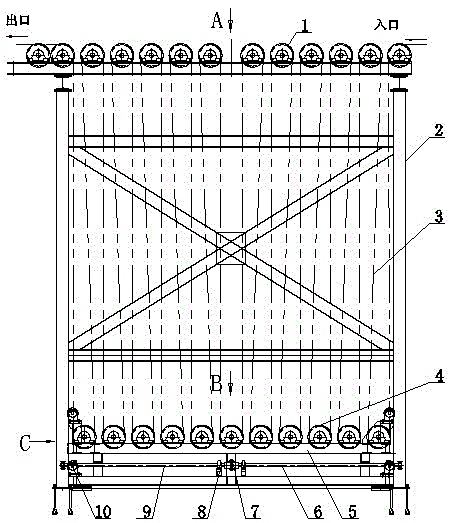

[0025] As shown in the figure, the vertical unpowered strip steel storage machine includes a frame 2, a movable roller set 4, a static movable roller set 1 and a looser car body 5, and the static movable roller set 1 is fixed On the top of the frame 2, the movable set of rollers 4 is fixed on the top of the looper body 5, and the looper body 5 is slidably connected in the frame 2. The looper rolls of the set of roll sets 4 and 1 form a staggered arrangement, and the two ends of the set of static set rolls 1 are respectively the inlet of the stocker and the outlet of the stocker. The two ends of the looper car body 5 are symmetrically arranged with a guiding mechanism, and the said guiding mechanism is composed of a gear guiding wheel 11 fixed on the looper car body 5, and a gear guiding wheel fixed on the frame 2. The toothed rack 12 that is meshed with the spur wheel 11 is formed. A balance shaft is connected between the rotating shafts of the two gear guide wheels 11, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com