An automatic packaging equipment for small bread processing

A bread and equipment technology, applied in packaging, transportation packaging, food packaging, etc., can solve the problems of low efficiency and labor consumption, and achieve the effect of ensuring quality, improving efficiency, and realizing ventilation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

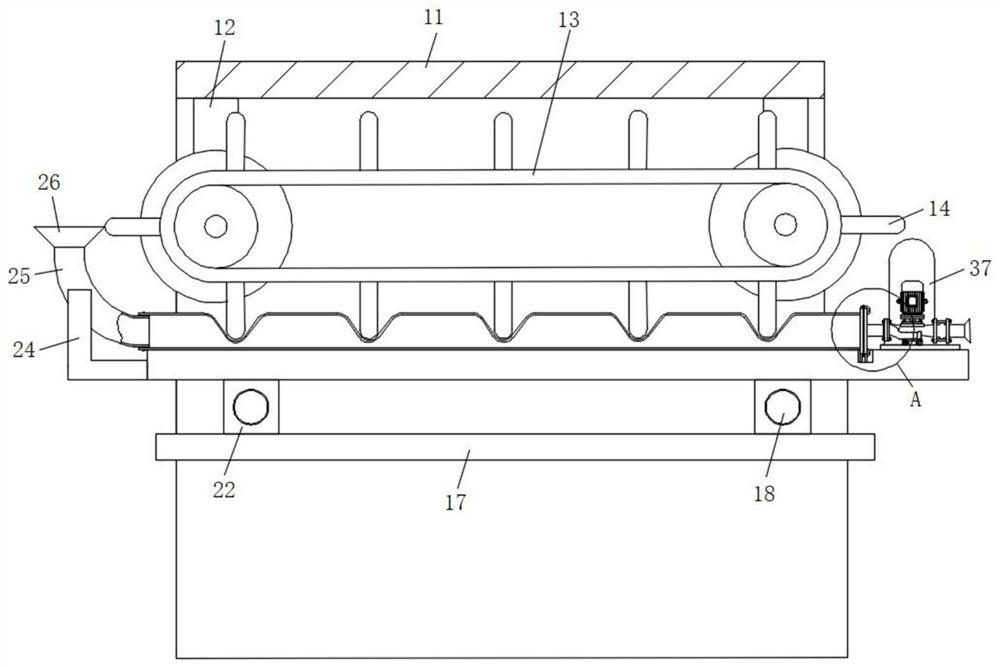

[0032] refer to Figure 1-5, an automatic packaging device for small bread processing, comprising a feeding mechanism and a dispersing mechanism, the feeding mechanism includes a supporting seat 1, the dispersing mechanism includes a supporting seat 2, and the upper ends of the supporting seat 1 and the supporting seat 2 are respectively equipped with conveying Belt one 3 and conveyor belt two 4, conveyor belt one 3 and conveyor belt two 4 go to the east through the motor, and the upper ends of conveyor belt one 3 and conveyor belt two 4 are respectively provided with sealing dish one 5 and sealing dish two 6, and sealing dish one 5, one side of the top surface is connected with a feeding funnel 7, a partition plate 8 is also fixed on the belt surface of the conveyor belt 2 4, and an ultraviolet sterilizing lamp 9 is also fixed on the top surface of the sealing dish 1 5 and the sealing dish 2 6 to disperse The side of the mechanism away from the feeding mechanism is also provi...

Embodiment 2

[0035] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, balls are installed on the bottom surface of the mounting block 22, and rolling grooves are provided on the top surface of the mounting plate 17, and the balls are placed in the rolling grooves.

[0036] In this embodiment, the mounting block 22 is rollingly connected to the top surface of the mounting plate 17, thereby making the movement of the mounting block 22 more stable, thereby ensuring a better sealing effect for continuous filling of the device.

Embodiment 3

[0038] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, four supporting seats 1 and two supporting seats 2 are provided and fixed on the working surface in a rectangular shape.

[0039] Partition plate 8 is provided with multiple and is evenly fixed on the belt surface of conveyer belt two 4, and ultraviolet sterilizing lamp 9 is all provided with multiple and is evenly installed on sealing dish one 5 and sealing dish two 6 inner top surfaces.

[0040] In this embodiment, a plurality of ultraviolet sterilizing lamps 9 are fixedly installed on the inner top surfaces of the first sealing dish 5 and the second sealing dish 6, so that the small bread can be continuously sterilized during transportation, and the small bread is well guaranteed. The quality of the bread packs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com