Silicon wafer separating device

A substrate and negative pressure technology, which is applied in the field of silicon wafer processing equipment, can solve problems such as unfavorable fragmentation, water reduction, and negative pressure adsorption efficiency, and achieve the effects of improving work efficiency, improving adsorption force, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

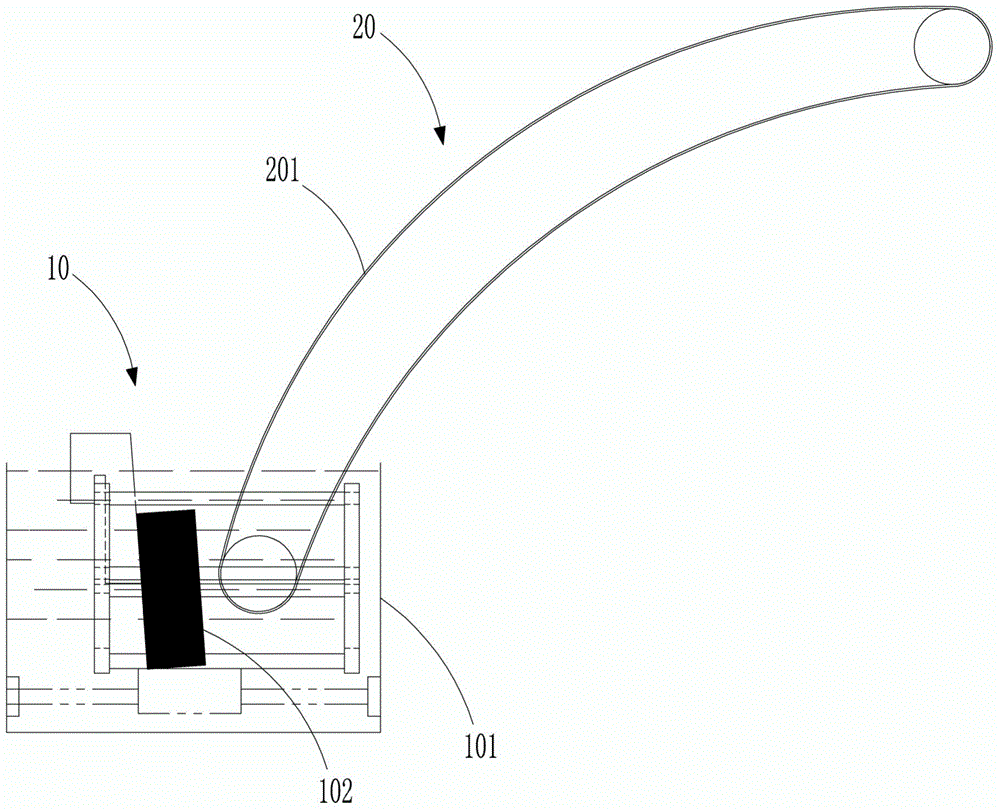

[0015] as attached figure 1 and attached figure 2 As shown, a slicer device includes a feeding unit 10, a suction unit 20 and a negative pressure unit 30. The feeding unit 10 is arranged in a water tank 101, wherein, the feeding unit 10 is placed with There is a substrate stack 102 of a plurality of substrates, each substrate is arranged along a substantially vertical plane; the suction unit 20 includes a conveyor belt 201, and the conveyor belt 201 is provided with a number of negative pressure adsorption holes communicated with a negative pressure power source, Conveyor belt 201 has part to be arranged in water tank 101 and this part extends to feeding unit 10, when substrate pile 102 is advanced along feeding direction, the substrate in substrate pile 102 can be one by one by the negative on conveyer belt 201. The pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com