Novel washable feeder

A flushing feeder, a new type of technology, applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of inconvenient angle adjustment, unclean cleaning, inconvenient use, etc., to save manpower, Good cleaning effect and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

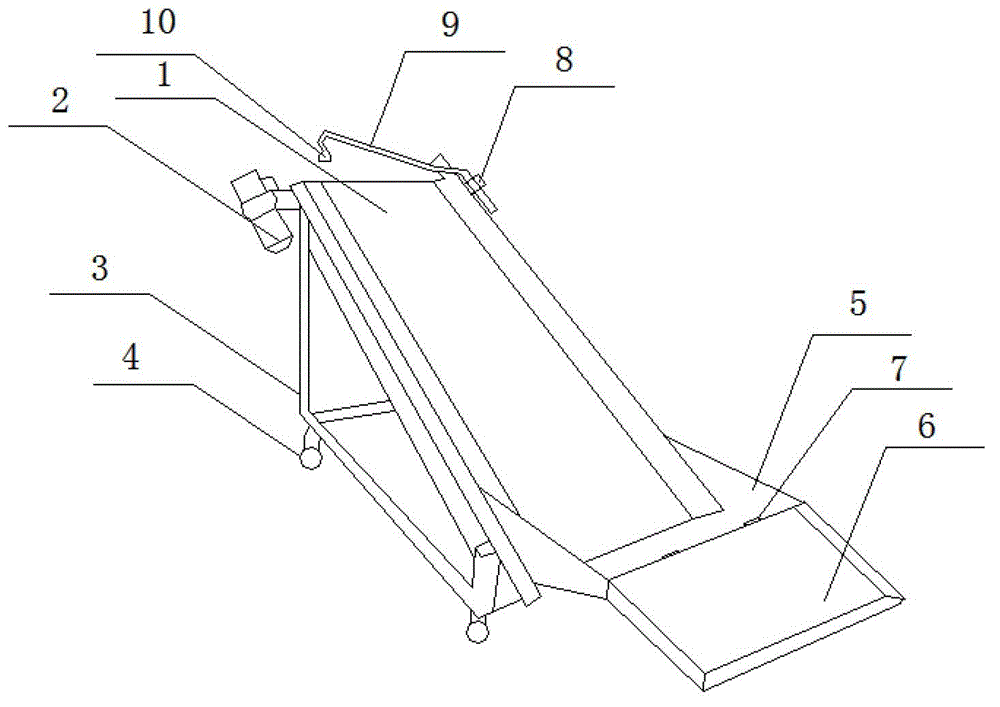

[0008] refer to figure 1 , this specific embodiment adopts the following technical solutions: it includes a material channel 1, a motor 2, an underframe 3, a roller 4, a material channel opening 5, a transfer material plate 6, a folding hinge 7, a fixing device 8, a water pipe 9 and a nozzle 10, A material channel 1 is arranged above the base frame 3, a roller 4 is provided below the base frame 3, a motor 2 is provided on one side of the material channel 1, and a fixing device 8 is provided on the other side of the material channel 1, and a fixing device 8 is fixed on the fixing device 8. The water pipe 9, the front end of the water pipe 9 is provided with a nozzle 10, and the bottom of the material channel 1 is provided with a material channel 5, and the material channel 5 and the transfer material plate 6 are connected by a folding hinge 7.

[0009] When this specific embodiment is used, water can be fed through the water pipe 9, the nozzle 10 sprays and flushes the feed cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com