Centralized air supply device of railway car equipment compartment and equipment compartment ventilation system

A technology of centralized air supply and ventilation system, applied in the heating/cooling, transportation and packaging of railway vehicles, railway vehicle body parts, etc. Use efficiency, help heat dissipation, and solve the effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

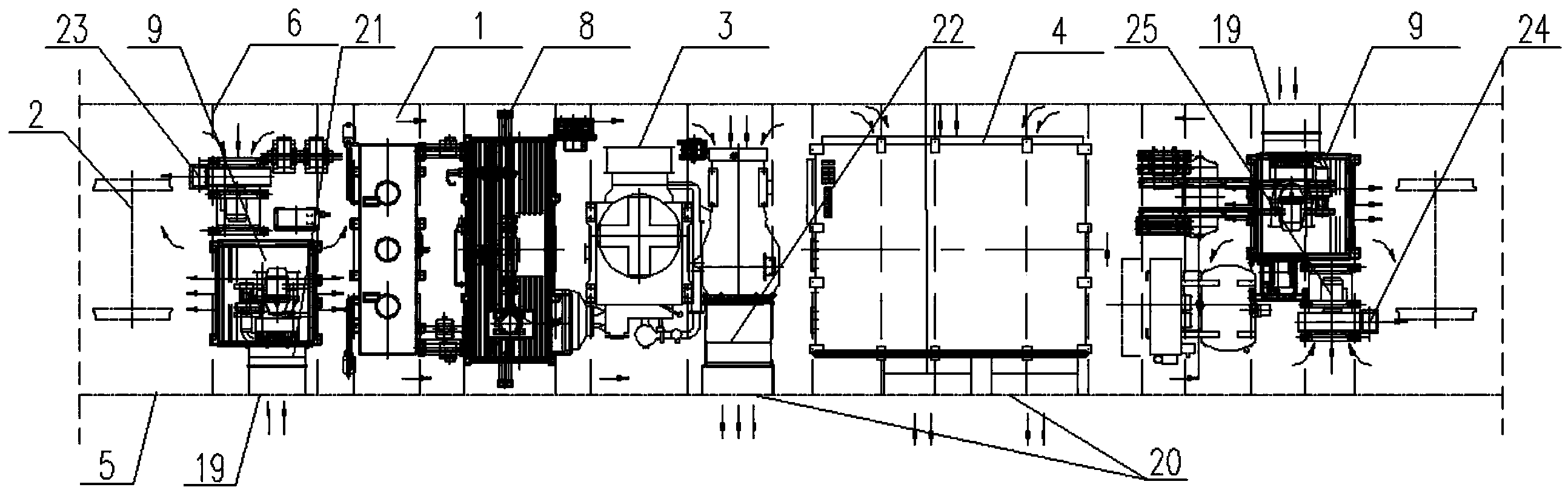

[0029] figure 1 As shown, the present invention provides a ventilation system for equipment cabins suitable for high-speed rail vehicles such as EMUs operating in severe environments such as high cold, strong wind and sand, and high temperature, including equipment cabins 1 for installing equipment under the vehicle, and equipment cabins 1 is installed between the two bogies under the car, and transformer 3, converter 4 and other equipment are installed in the equipment compartment 1.

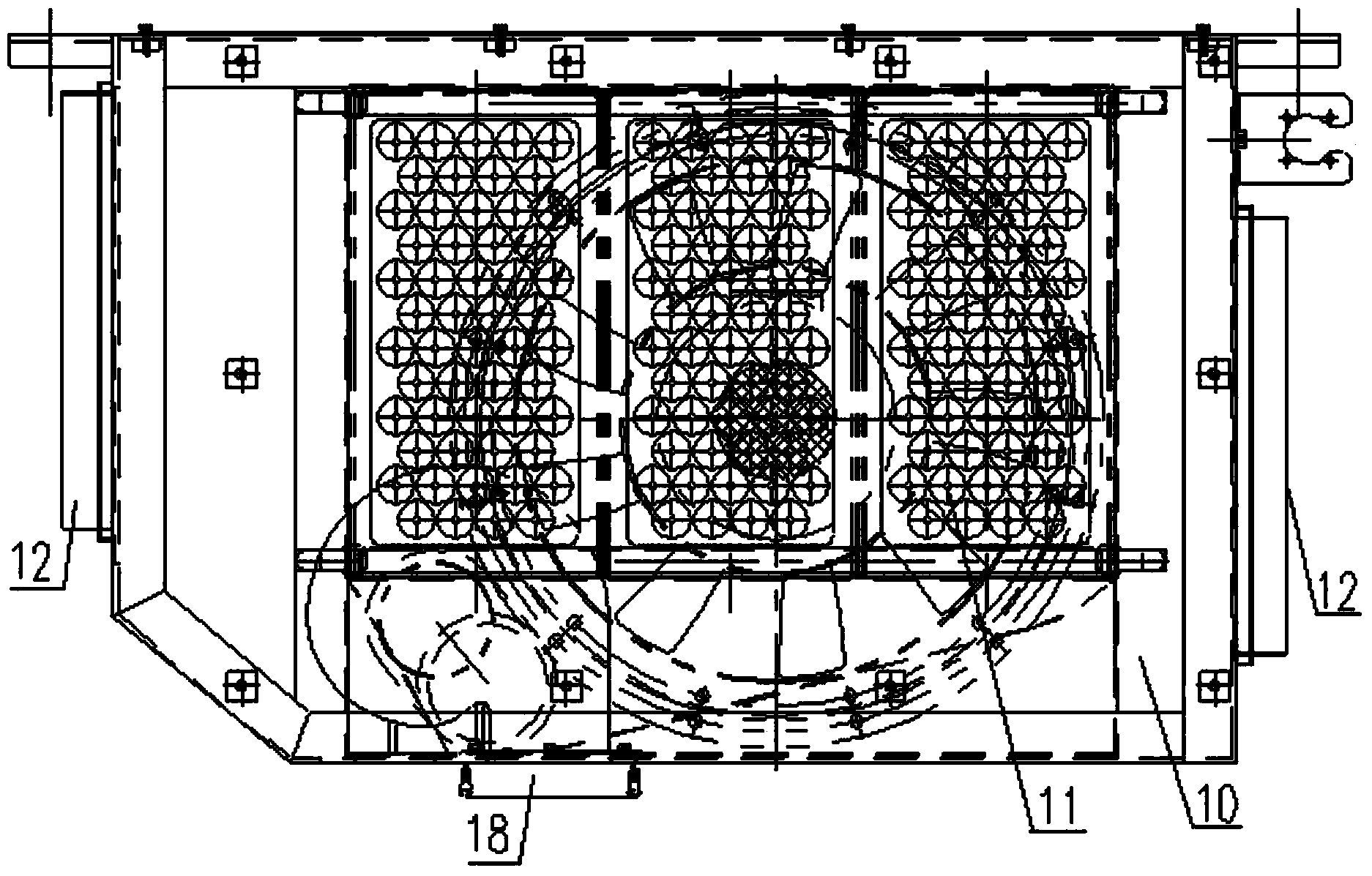

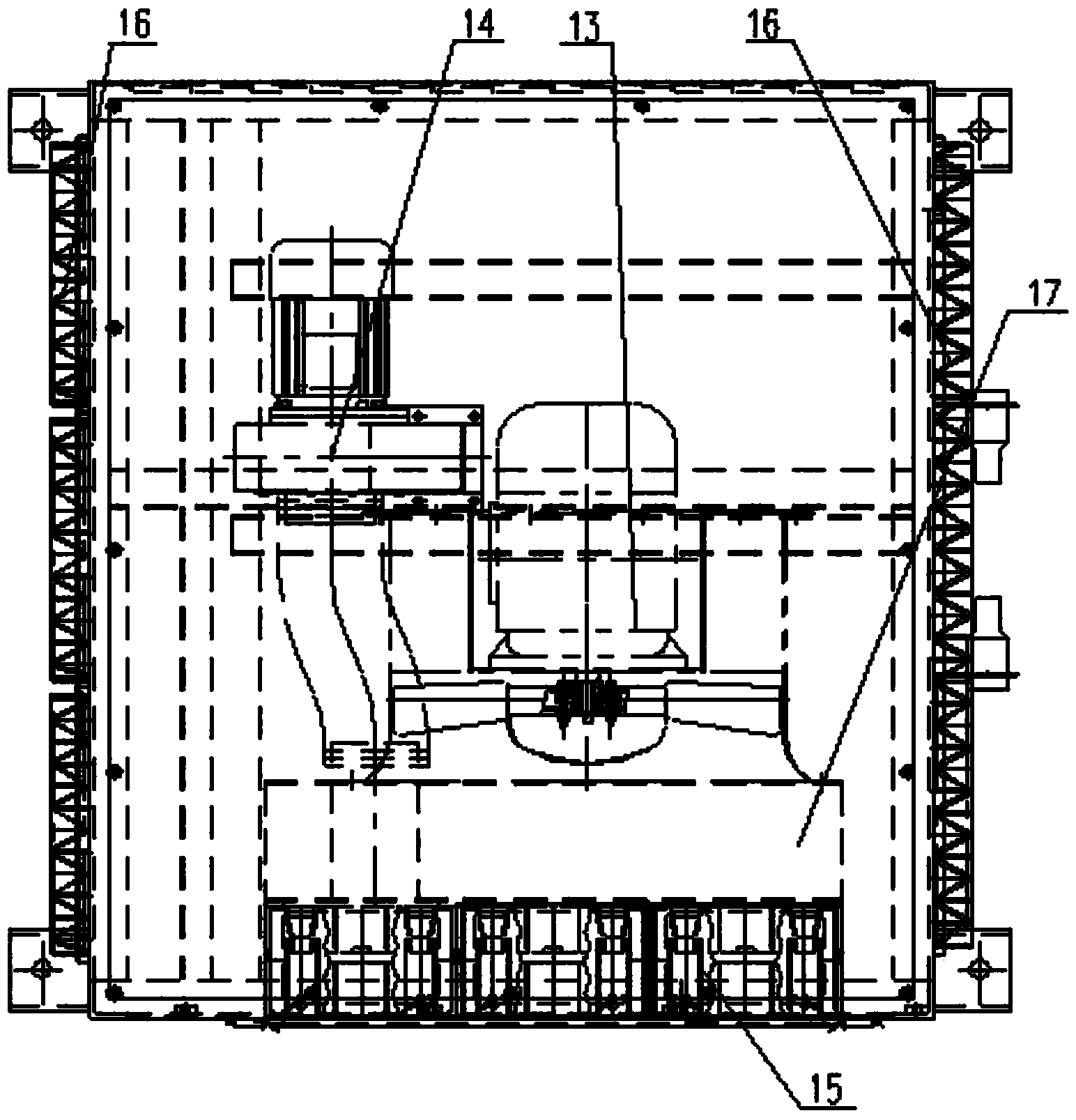

[0030] such as 1 and Figure 4 As shown, the equipment compartment 1 is composed of skirt plates 5 located on both sides of the car body, end plates 6 at both ends, a bottom plate 7 and a frame 8, the frame 8 is fixed on the crossbeam of the car body chassis by bolts, the end plates 6, skirt plates 5 is fixedly connected to the frame 8 by bolts, the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com