Method of Automatic Detection and Tracking Weld Seam

An automatic detection and welding torch technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of reducing automatic welding efficiency, heavy workload, and scrapped steel plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

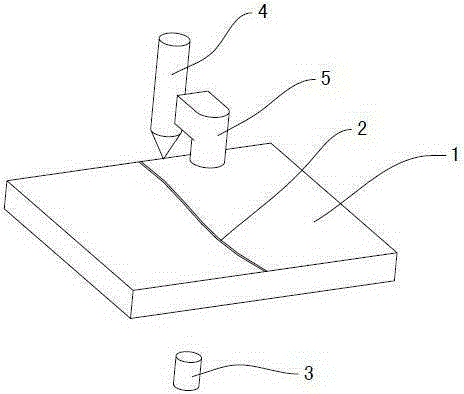

[0044] Figure 1~5 It is the best embodiment of the method for this automatic detection and tracking weld seam, below in conjunction with the attached Figure 1~5 The present invention will be further described.

[0045] refer to figure 1 The welding equipment used in the method for automatically detecting and tracking welds includes a workpiece 1, a welding torch 4, a camera 5 and a bottom light source 3. The welding torch 4 and the camera 5 are relatively fixed on the upper side of the workpiece 1, and the welding torch 4 is connected to drive it along the X axis. The moving X-axis motor and the Y-axis motor (not shown in the figure) driving it to move along the Y-axis, the bottom light source 3 is arranged on the lower side of the two workpieces 1 .

[0046] The method for automatically detecting and tracking weld seams includes the following steps:

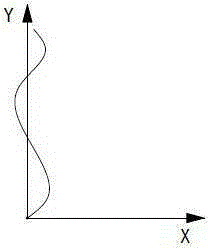

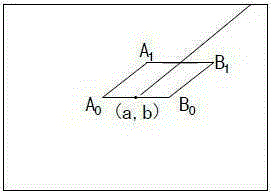

[0047] Step 1, refer to Figure 1~2 , the workpiece 1 to be welded is pre-assembled, and there is a gap between the work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com