Cleaning device for electro-galvanizing materials

A cleaning device and electro-galvanizing technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve customer complaints, low production efficiency, cleaning is not in place, etc., to save time and quality The effect of stabilizing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

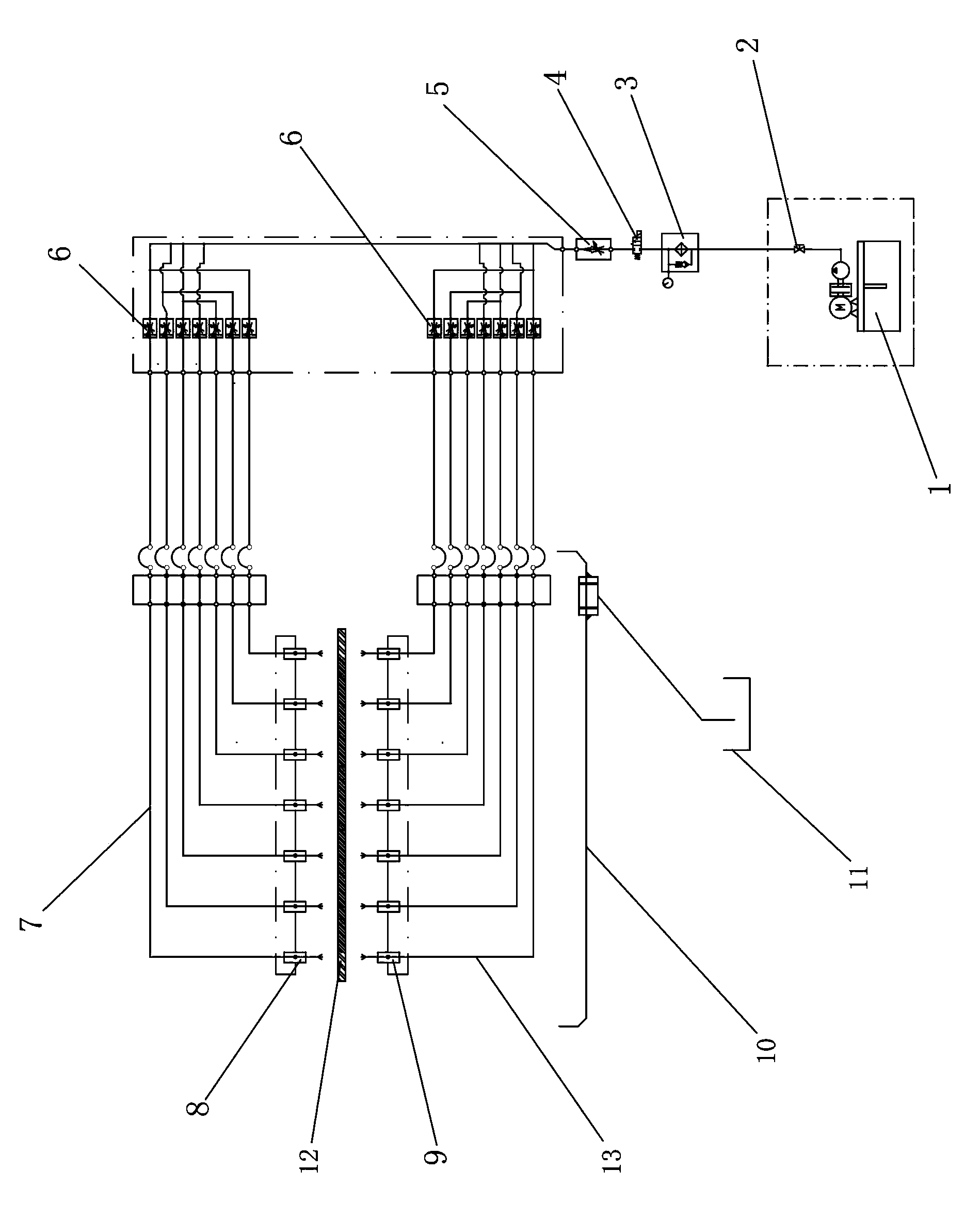

[0009] Such as figure 1 As shown, an electro-galvanized material cleaning device includes an air diaphragm pump 1, a filter 3, a number of upper pipes 7, a number of lower pipes 13, a return tray 10, and a return tank 11. The filter 3 passes through a shut-off valve 2 and The air diaphragm pump 1 is connected; the output end of the filter 3 is sequentially connected with a control directional valve 4 and a first flow regulating valve 5; the input ends of a number of upper pipelines 7 and a number of lower pipelines 13 are respectively connected to the first flow regulating valve 5 The output ends of the upper pipes 7 and the lower pipes 13 are respectively connected to the upper nozzle 8 and the lower nozzle 9; the upper nozzle 8 is located above the lower nozzle 9; the upper pipes 7 and the lower pipes A flow regulating valve 6 is respectively provided on the road 13; a return tray 10 is provided at the bottom of a number of lower pipes 13; the return tray 10 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com