Continuous discharge device of evaporation and crystallization equipment

A discharge device and evaporation crystallization technology, which is applied in the field of continuous discharge device of evaporation crystallization equipment, can solve the problems of difficult discharge, crystal hardening, blockage of the discharge port, etc., and achieve the effect of saving energy consumption and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

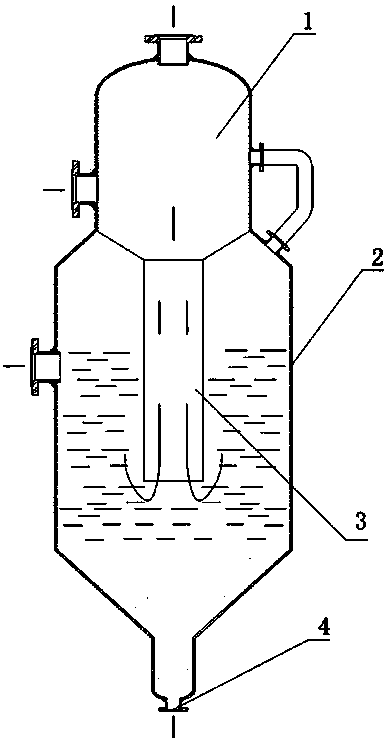

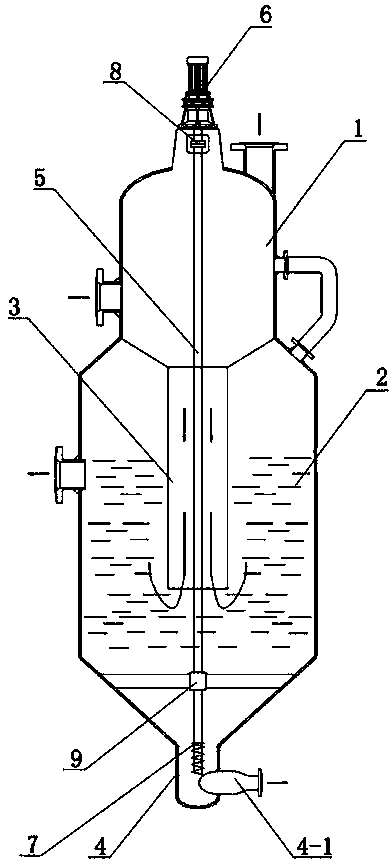

[0012] Embodiment: The structure of the continuous discharge device of the evaporation crystallization equipment provided by the invention is as follows figure 2 As shown, it includes an evaporator 1 and a crystallizer 2 connected to each other. The evaporator 1 is connected to the top of the crystallizer 2. The outer diameter of the evaporator 1 is smaller than the outer diameter of the crystallizer 2. It is fixed by the shrinking shoulder on the top of the crystallizer 2. Connections also have interconnected vapor phase tubes on the shoulders.

[0013] There is an elutriation leg 4 at the conical bottom of the crystallizer 2, and the side wall on the elutriation leg 4 is provided with a square variable-diameter discharge opening 4-1, and the section of the discharge opening 4-1 is a square, and its tube The diameter shrinks along the discharge direction. The bottom of the evaporator 1 has a central circulation pipe 3 extending into the crystallizer 2, the outlet of the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com