Feeder automation test system with automatic interference input function

A feeder automation and testing system technology, applied in the field of feeder automation, can solve the problems of power supply reliability and power supply quality reduction, and achieve the effect of improving power supply reliability and power supply quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

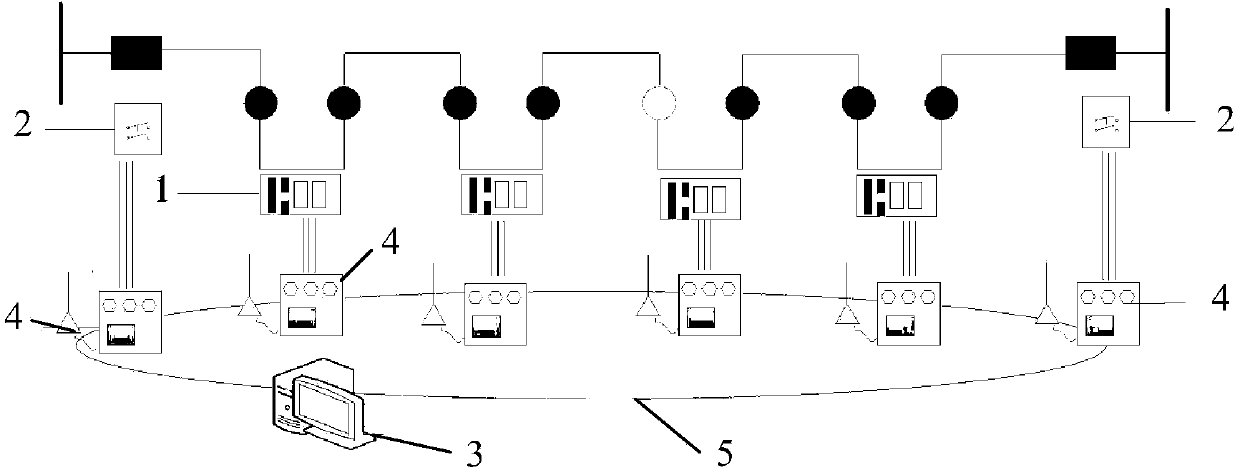

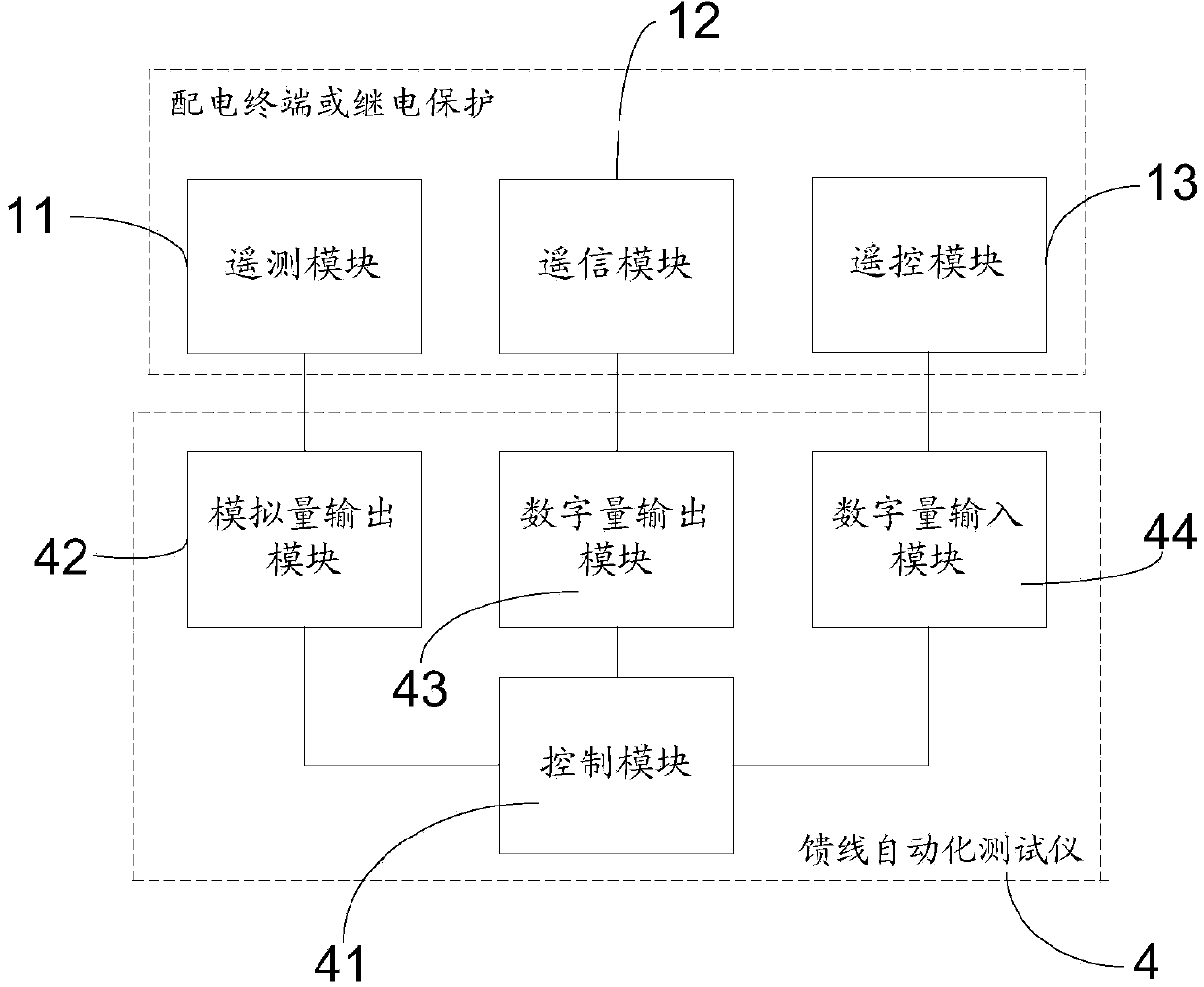

[0016] see figure 1 and figure 2 , the figure shows a feeder automatic test system with automatic disturbance input of the present invention, the power distribution network includes a power distribution terminal 1 and a relay protection 2, and the power distribution terminal 1 and the relay protection 2 both have a telemetry module 11, Remote signaling module 12 and remote control module 13, the feeder automatic test system of the present invention includes several feeder automatic testers 4 connected with power distribution terminal 1 or relay protection 2 respectively, and connected with all feeder automatic testers 4 through network system 5 console3.

[0017] Feeder automatic tester 4 comprises control module 41, analog quantity output module 42, digital quantity output module 43 and digital quantity input module 44, and control module 41 is connected with analo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com