Experimental device and test method for the relationship between constraint pressure and extrusion deformation of tunnel face

A technology of restraint pressure and test device, which is applied in the direction of mechanical solid deformation measurement, soil material test, material inspection products, etc., can solve the problems of reducing construction speed, small restraint pressure, and increasing construction cost, so as to ensure stability and reduce construction cost. , the effect of improving the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

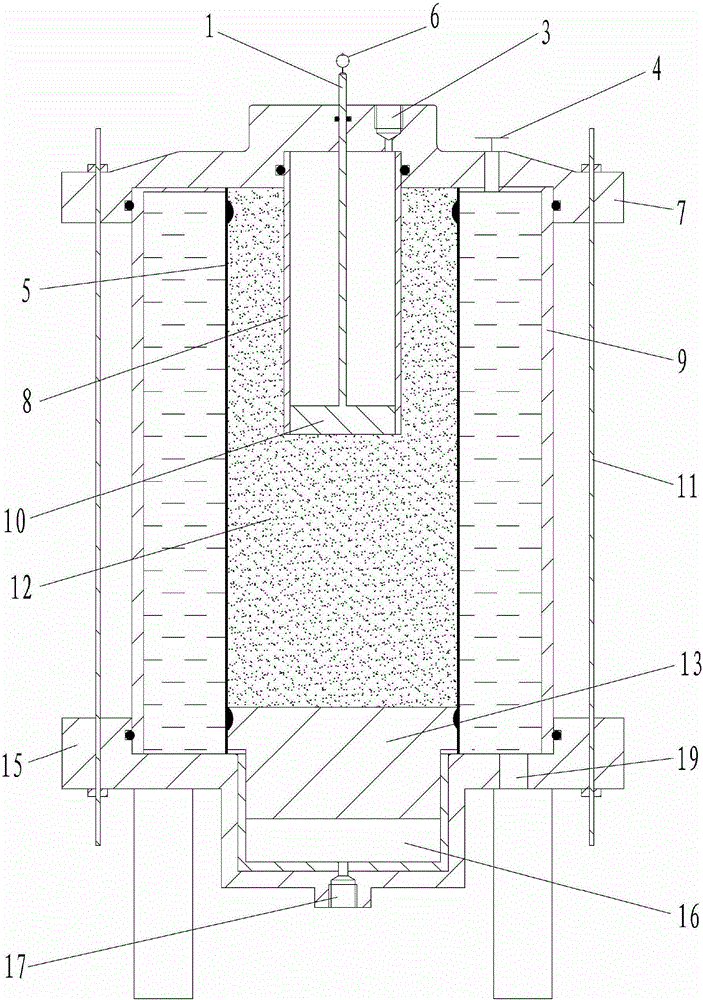

[0015] figure 1 Shown, a tunnel face constraint pressure and extrusion deformation test device, its composition is:

[0016] The side wall 9 is sealed and embedded with the upper cover 7 and the base 15 to form a cylindrical pressure chamber; the outer side of the upper cover 7 and the base 15 is also screwed through the pull rod 11, and the groove in the middle of the upper surface of the base 15 is fixed with a Oil cylinder 16, the piston 13 of oil cylinder 16 extends upward into the pressure chamber, and the oil inlet and outlet joint 17 of oil cylinder 16 passes through the base 15; the upper cover 7 is provided with an exhaust valve 4 near the side wall 9; the cylinder groove in the middle of the bottom surface of the upper cover 7 The upper seal is embedded with a cylinder barrel 8 with a diameter smaller than the oil cylinder 16. The cylinder groove is provided with a vent hole 3 passing through the upper cover 7. The piston 10 of the cylinder barrel 8 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com